Aluminum-magnesium-lithium alloys, and methods for producing the same

a technology of aluminum-magnesium-lithium alloys and alloys, which is applied in the field of new aluminum-magnesium-lithium alloys, can solve the problems of reducing ductility and too much lithium, and achieve the effects of reducing density, improving strength, and reducing ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0035]Twelve book mold ingots were produced, the compositions of which are provided in Table 1, below (all values in weight percent).

TABLE 1Example 1 Alloy CompositionsAlloyMgLiCuZn12.890.000022.800.210032.900.870042.801.200052.701.600065.030.000074.750.230084.750.870094.551.2000105.550.8500115.040.000.190.54124.500.860.180.46

[0036]Unless otherwise indicated, all alloys contained the listed elements, from about 0.10 to 0.13 wt. % Zr, about 0.60 wt. % Mn, not more than about 0.04 wt. % Fe, not more than 0.03 wt. % Si, about 0.02 wt. % Ti, the balance being aluminum and other elements, where the other elements did not exceed more than 0.05 wt. % each, and not more than 0.15 wt. % total of the other elements.

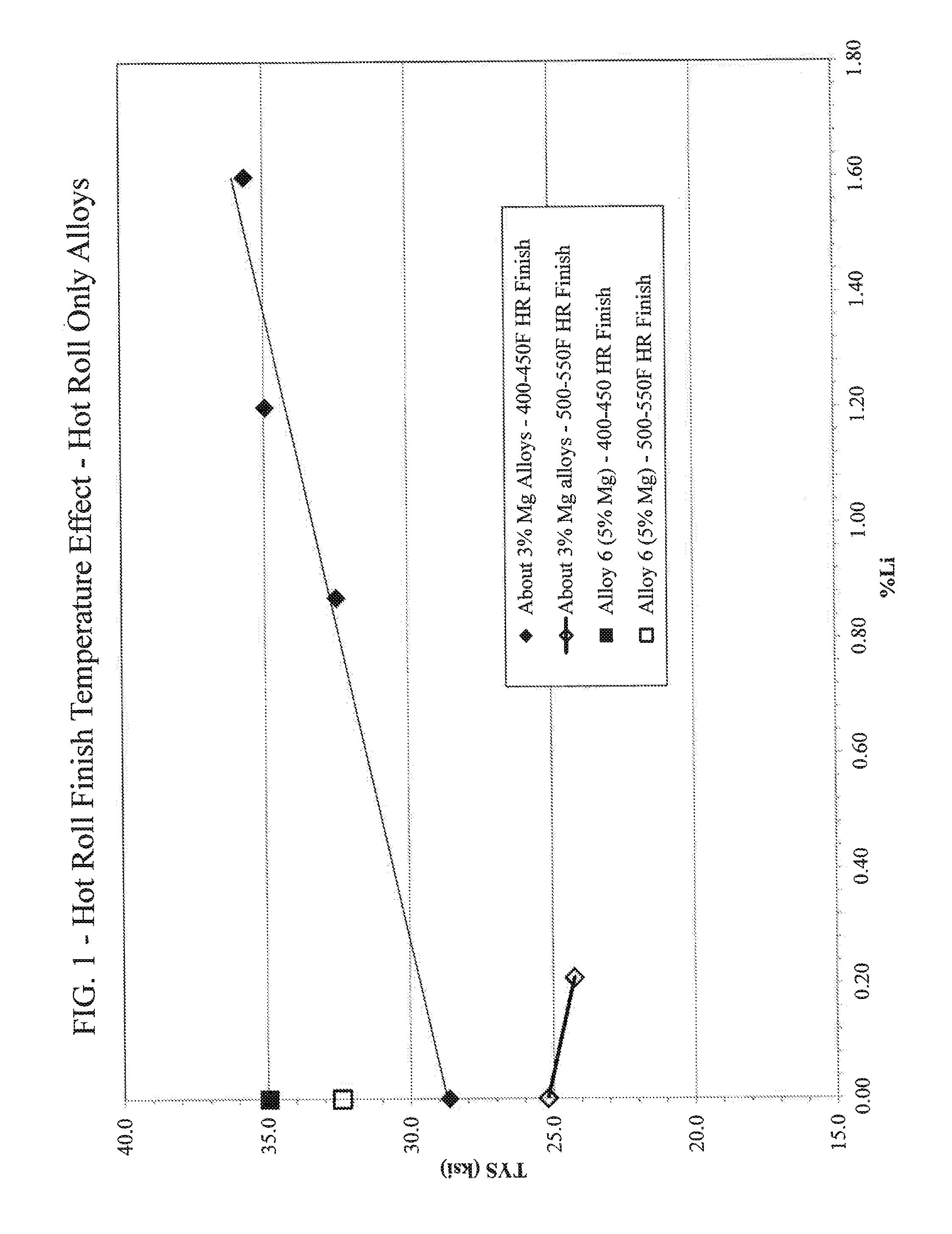

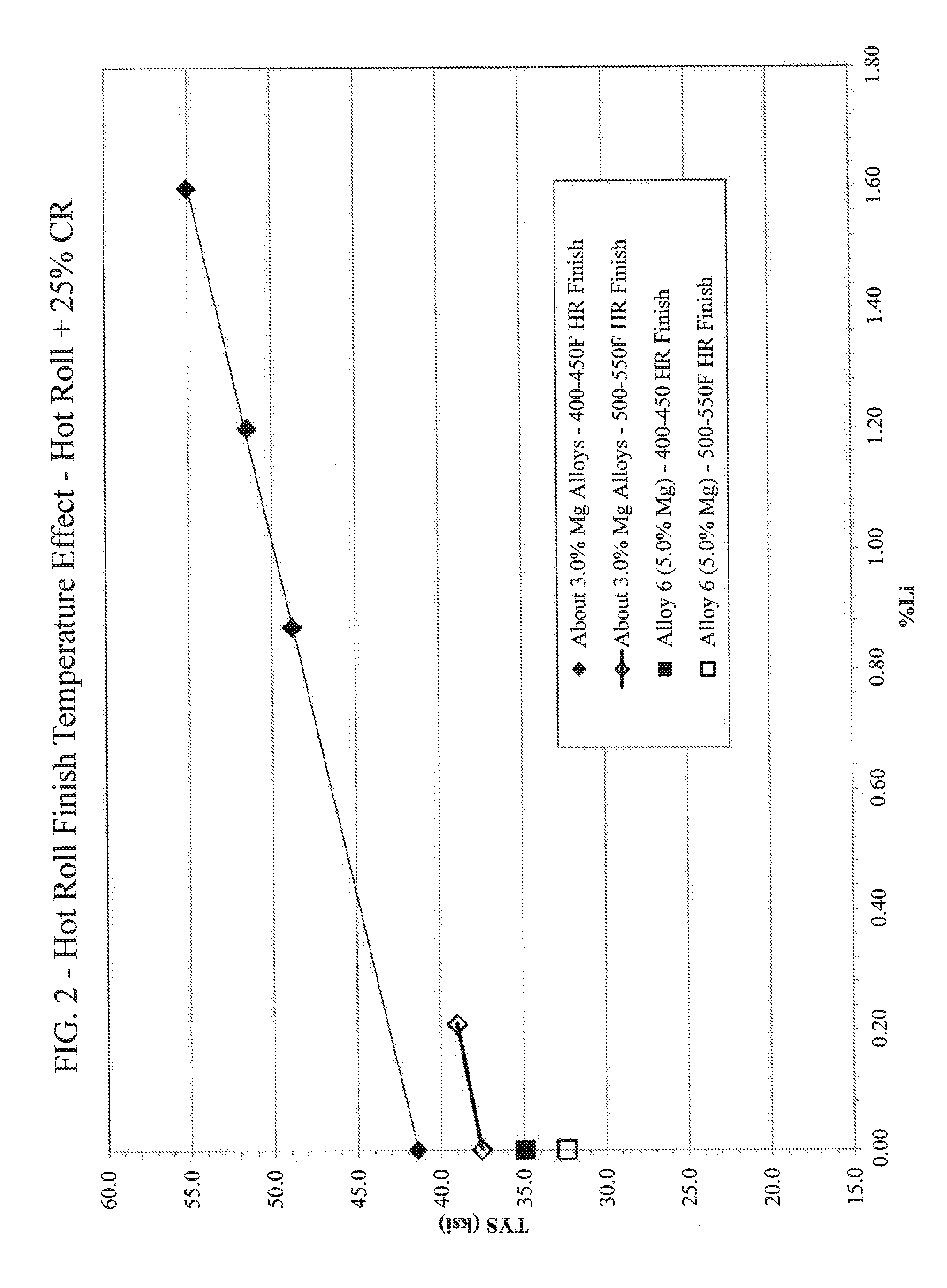

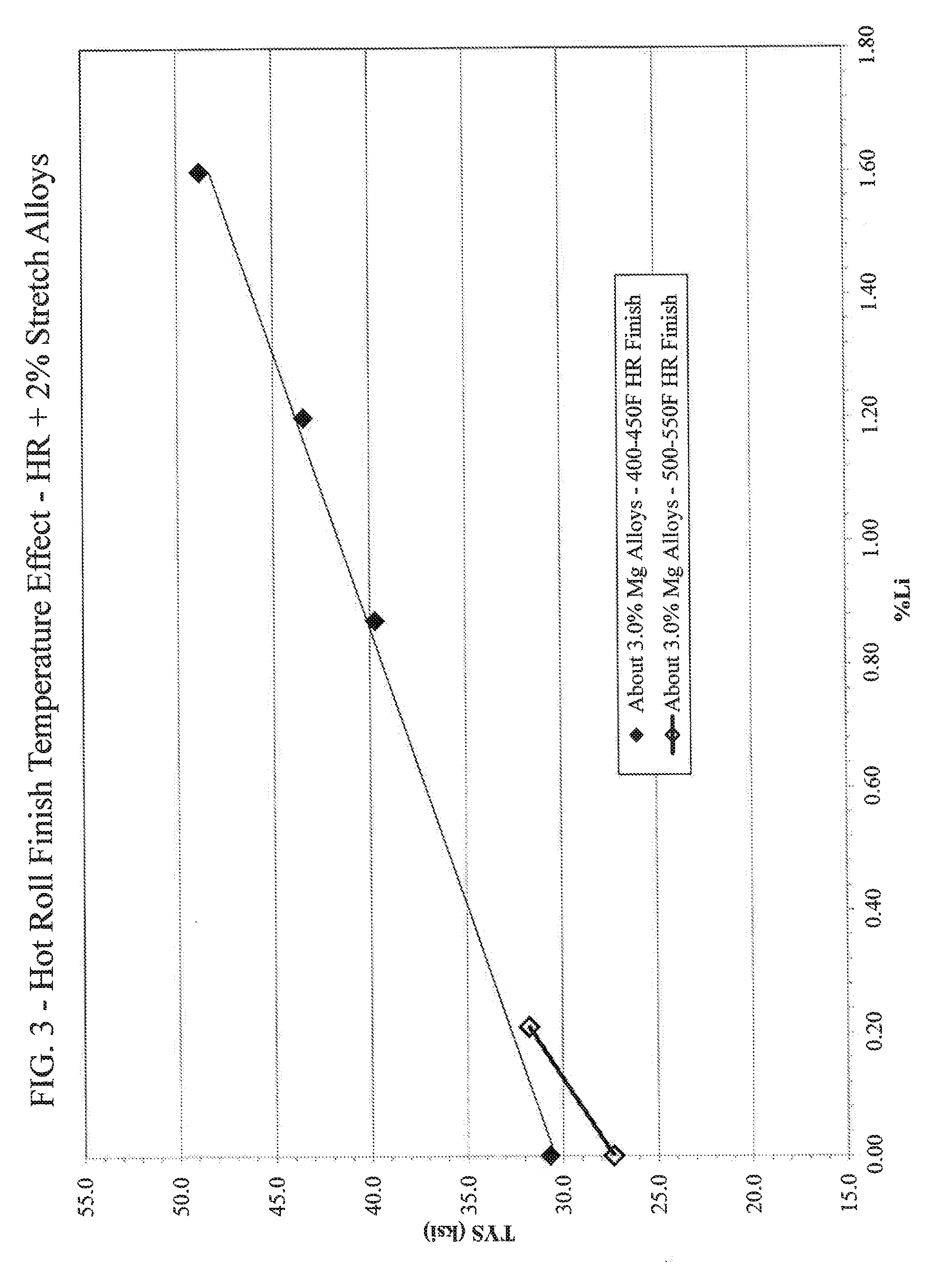

[0037]The alloys were cast as approximately 2.875 inch (ST)×4.75 inch (LT)×17 inch (L) ingots that were scalped (machined) to about 2 inches thick. Alloys 10-12 were then homogenized. Each ingot was then hot rolled to a gauge of about 0.25 inch. The finish hot rolling temperature v...

example 2

[0041]Fourteen book mold ingots were produced, the compositions of which are provided in Table 8, below (all values in weight percent).

TABLE 8Example 2 Alloy CompositionsAlloyMgLiZnCuAg134.422.010.960.350.24144.332.091.870.350.23154.532.130.970.950.24164.482.181.920.950.24174.412.030.970.350.65184.382.041.900.360.65194.412.060.980.950.66204.362.121.890.890.62214.372.081.440.650.44224.312.222.820.640.43234.432.161.441.850.45244.452.181.480.680.91254.452.061.450.670.45264.402.131.450.670.44

[0042]Unless otherwise indicated, all alloys contained the listed elements, from about 0.10 to 0.012 wt. % Zr, not more than about 0.03 wt. % Fe, not more than 0.04 wt. % Si, about 0.02 wt. % Mn, about 0.02 wt. % Ti, the balance being aluminum and other elements, where the other elements did not exceed more than 0.05 wt. % each, and not more than 0.15 wt. % total of the other elements. Alloy 25 contained about 0.24 wt. % Si. Alloy 26 contained about 0.87 wt. % Si.

[0043]The alloys were cast as approx...

example 3

[0047]Twenty-three book mold ingots were produced, the compositions of which are provided in Table 9, below (all values in weight percent).

TABLE 10Example 1 Alloy CompositionsAlloyMgLiMnCuZn272.21.10.550.05—282.51.00.58——293.31.00.54——303.51.10.56——314.11.10.57——322.91.10.54——333.11.00.29——343.21.1—0.01—353.01.01.10——363.01.01.60——373.01.00.56—0.10383.01.10.56—0.24392.91.10.57—0.51403.01.10.56—0.97413.01.10.56—1.90422.91.00.570.140.02433.11.10.560.29—442.91.10.560.48—453.11.00.560.250.50462.81.10.56——472.94—0.54——482.90.500.57——492.81.000.57——502.91.600.57——

Unless otherwise indicated, all alloys contained the listed elements, from about 0.10 to 0.14 wt. % Zr, not more than about 0.04 wt. % Fe, not more than 0.08 wt. % Si, the balance being aluminum and other elements, where the other elements did not exceed more than 0.05 wt. % each, and not more than 0.15 wt. % total of the other elements. Alloy 46 contained about 0.09 wt. % Zr, about 0.10 wt. % Fe and about 0.14 wt. % Si.

[0048]The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| exit temperature | aaaaa | aaaaa |

| exit temperature | aaaaa | aaaaa |

| exit temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com