Fuel supply device, fuel supply method and boat propulsion device

a fuel supply device and fuel supply technology, applied in the direction of valve details, fluid pressure control, special dispensing means, etc., can solve the problems of fuel pump idleness, insufficient negative pressure in the sub fuel tank, oil-film seal not provided inside the fuel pump, etc., and achieve the effect of efficient sucking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

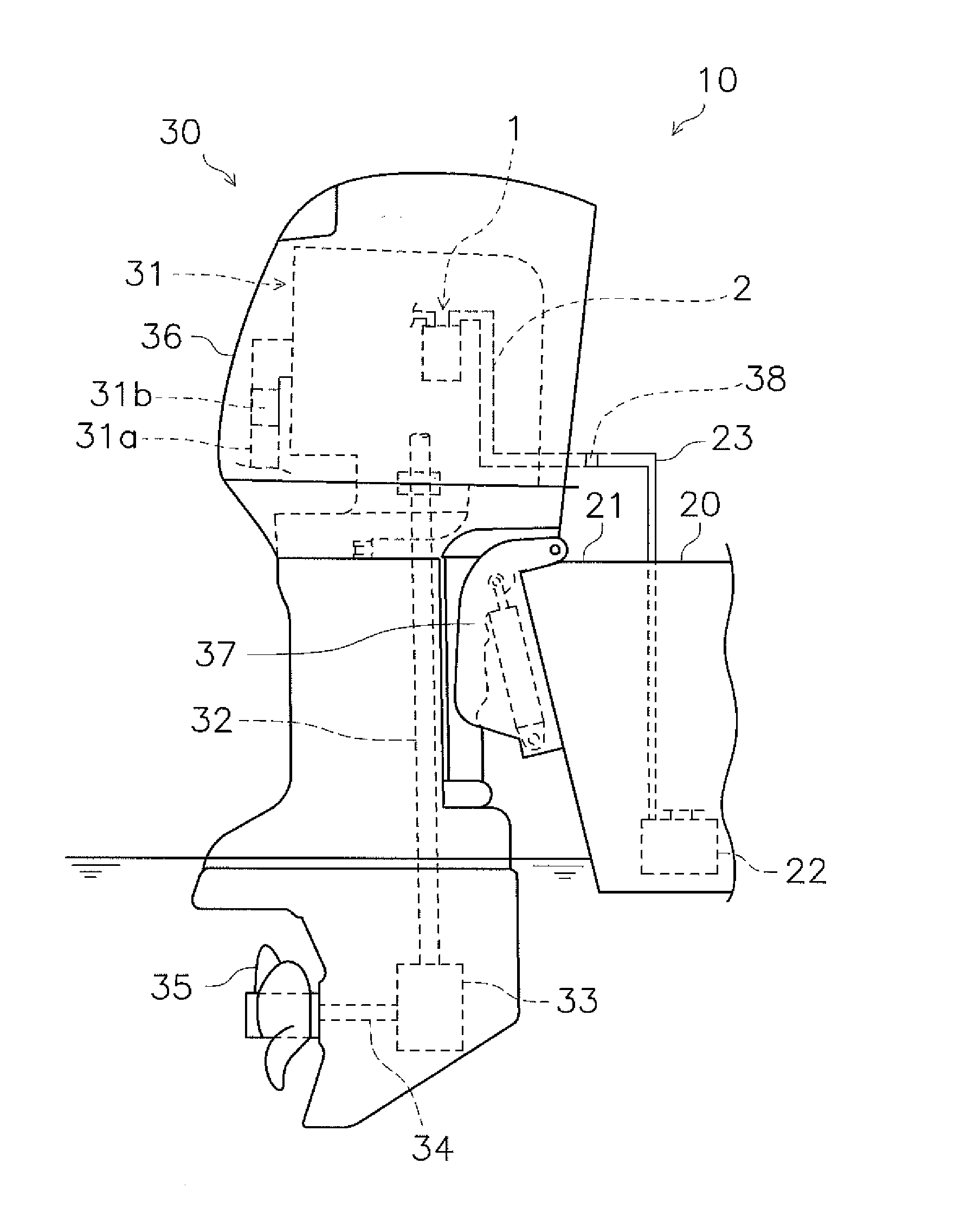

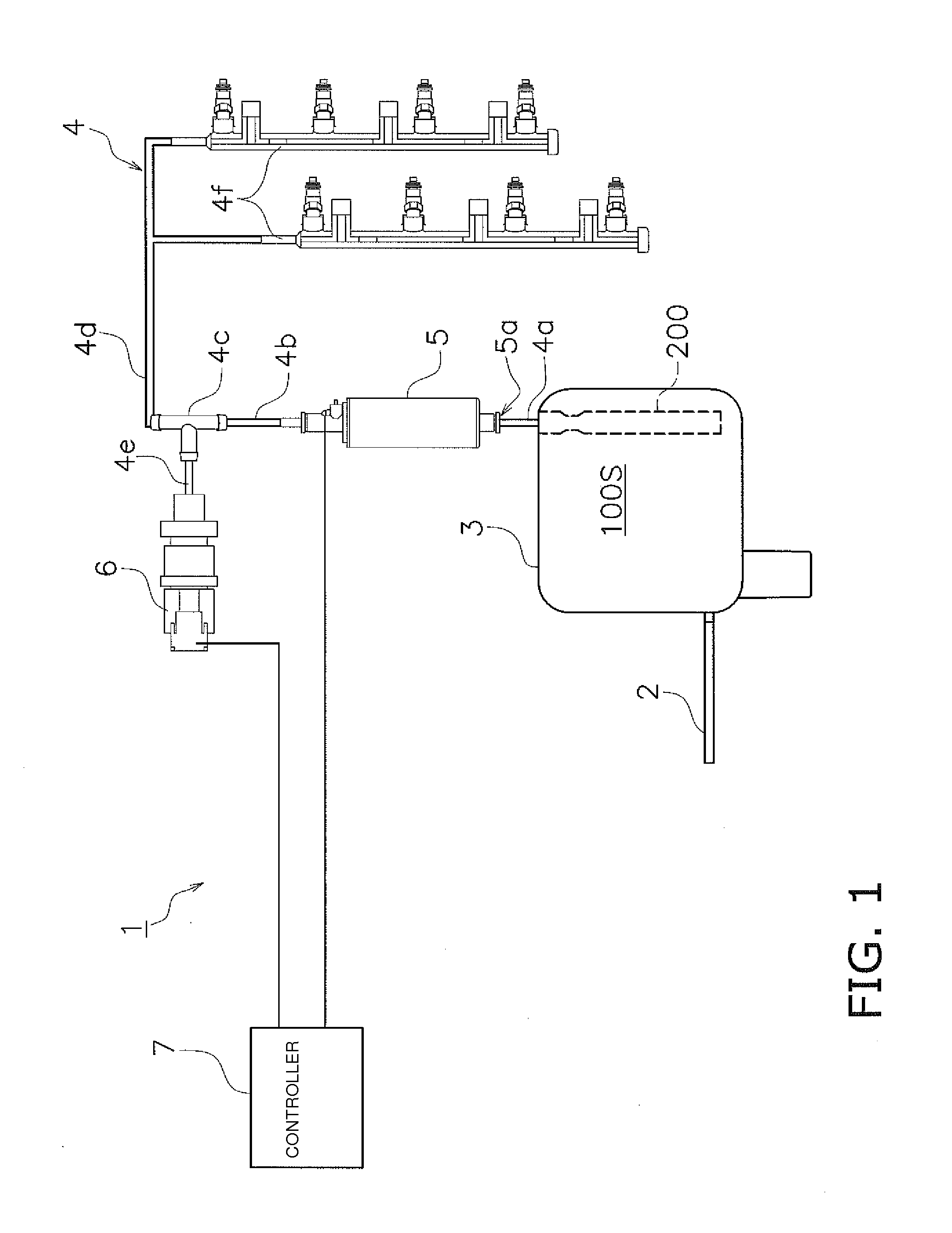

[0023]A structure of a fuel supply device 1 for supplying fuel to an engine will be hereinafter explained. FIG. 1 is a schematic diagram of a structure of the fuel supply device 1 according to a first preferred embodiment of the present invention.

[0024]The fuel supply device 1 includes a fuel supply pipe 2, a fuel tank 3, a fuel path 4, a fuel pump 5, a fuel pressure sensor 6, and a controller 7.

[0025]The fuel supply pipe 2 is connected to the fuel tank 3. The fuel supply pipe 2 directs the fuel to the fuel tank 3.

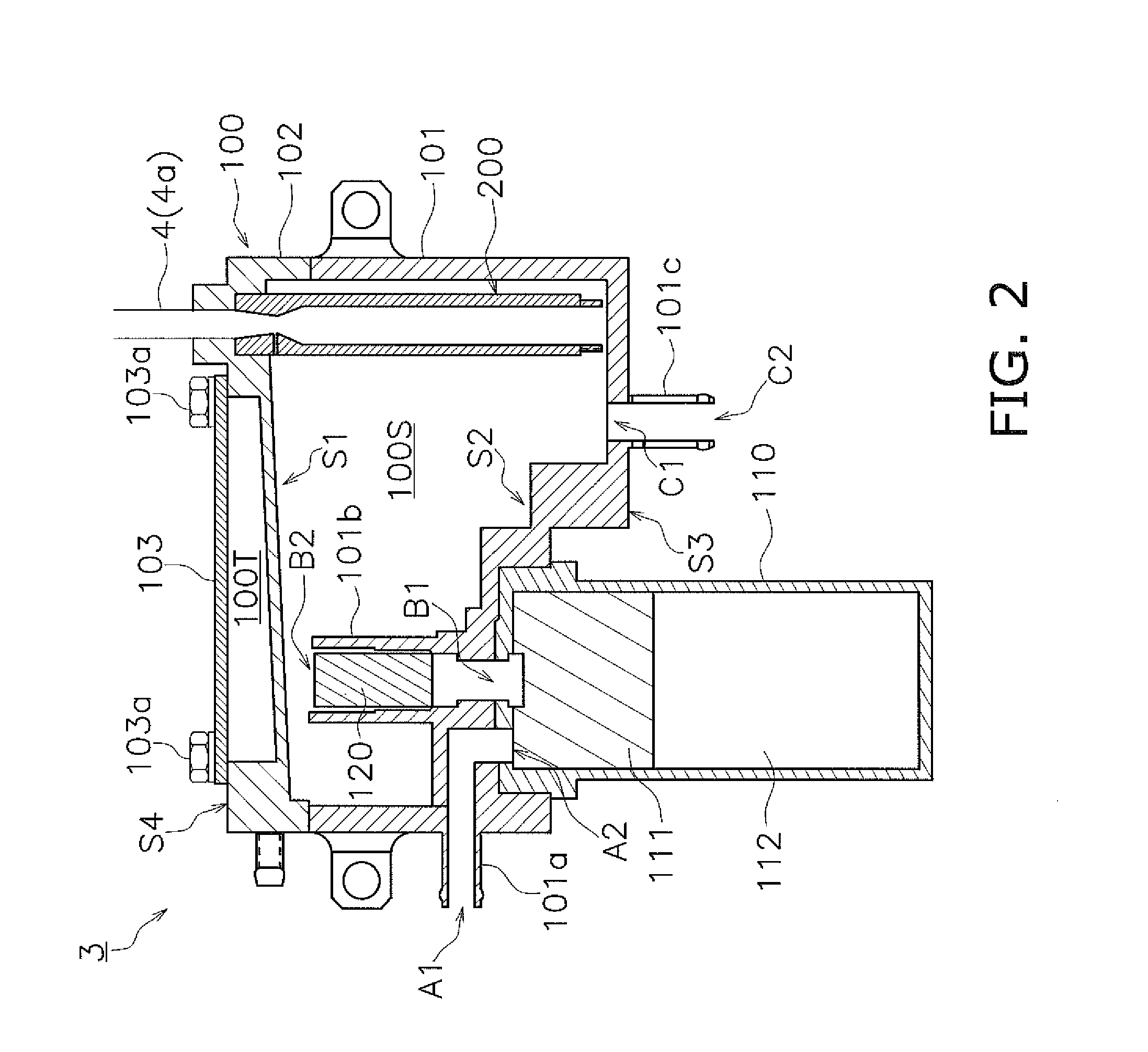

[0026]The fuel tank 3 includes a fuel storage region 100S configured to store the fuel fed thereto through the fuel supply pipe 2. The fuel storage region 100S is a sealed region with liquid tight properties and gas tight properties. The fuel storage region 100S does not include a port opened to the atmosphere. In the fuel storage region 100S, the vaporized fuel is produced as a result of vaporization of the liquid fuel. Thus, the fuel storage region 100S stores both the l...

second preferred embodiment

[0079]A structure of a fuel supply device 1A according to a second preferred embodiment of the present invention will be explained. FIG. 10 is a schematic diagram of the structure of the fuel supply device 1A according to the second preferred embodiment. The fuel supply device 1A is different from the fuel supply device 1 according to the first preferred embodiment in that the fuel supply device 1A is equipped with a regulator 8 and a return path 9 instead of the fuel pressure sensor 6 and the controller 7.

[0080]The regulator 8 is connected to the fuel path 4 (the fourth fuel hose 4e). The regulator 8 is configured to regulate the pressure of the fuel discharged from the fuel pump 5 to be a target value by releasing or diverting a surplus fuel existing in the fuel path 4 to the return path 9. The return path 9 is connected to the fuel tank 3 and the regulator 8. The fuel released from the regulator 8 returns to the fuel tank 3 through the return path 9. A self-priming pump is prefer...

third preferred embodiment

[0082]A structure of a fuel supply device 1B according to a third preferred embodiment of the present invention will be explained. FIG. 11 is a schematic diagram of the structure of the fuel supply device 1B according to the third preferred embodiment. The fuel supply device 1B is different from the fuel supply device 1 according to the first preferred embodiment in that the fuel supply device 1B utilizes a fuel tank 3B as a sub tank to store a fuel to be supplied to a vapor separator tank (hereinafter referred to as “VST”) 10.

[0083]The fuel supply device 1B includes the fuel tank 3B, a fuel pump 5B, and the VST 10.

[0084]The fuel tank 3B has a simple structure that is not provided with a filtration filter and so forth. The fuel tank 3B includes the fuel storage region 100S that is configured to store a fuel to be fed thereto through the fuel supply pipe 2. The fuel storage region 100S is a sealed region with liquid tight properties and gas tight properties. The fuel storage region 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com