Electric compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

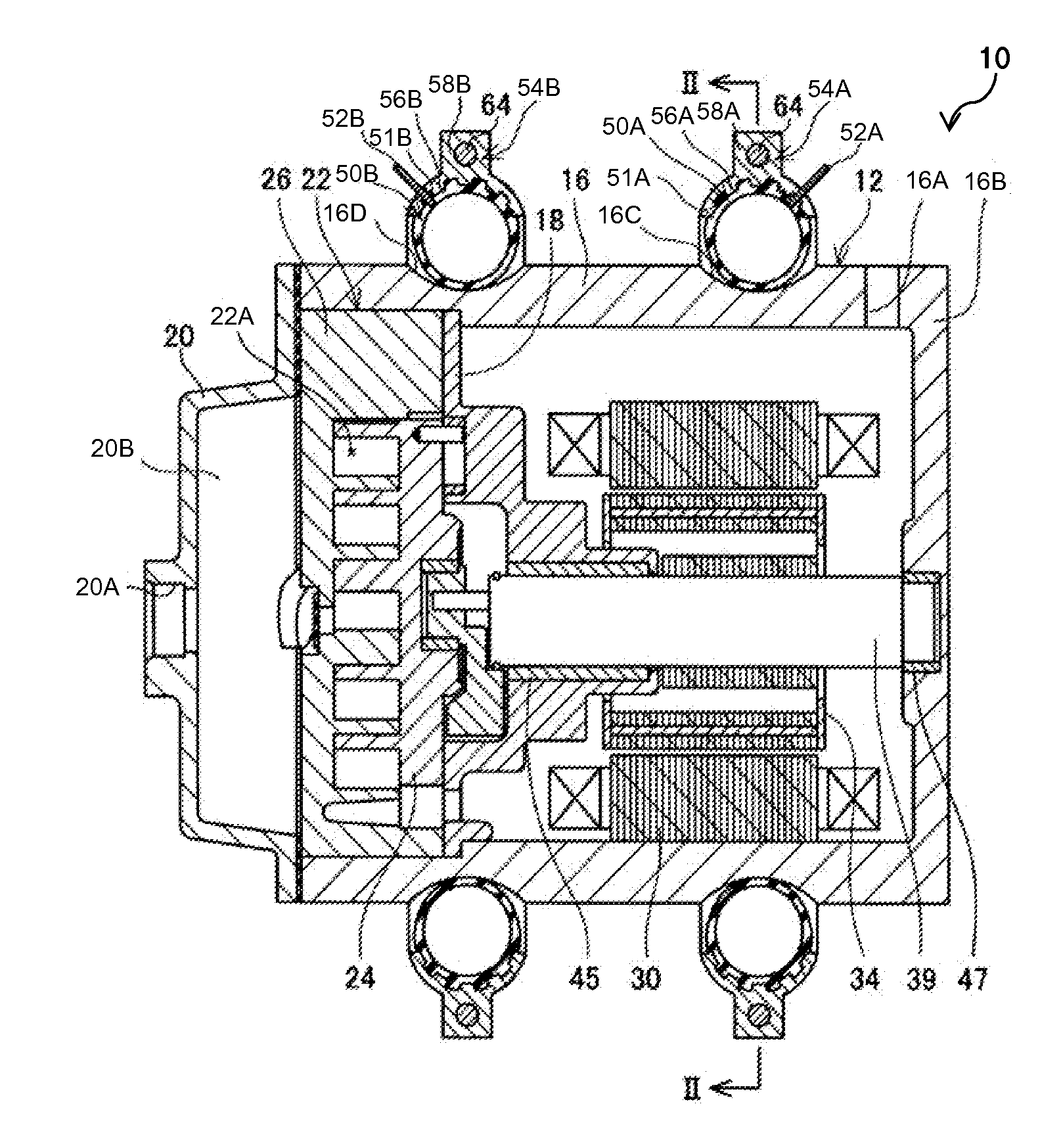

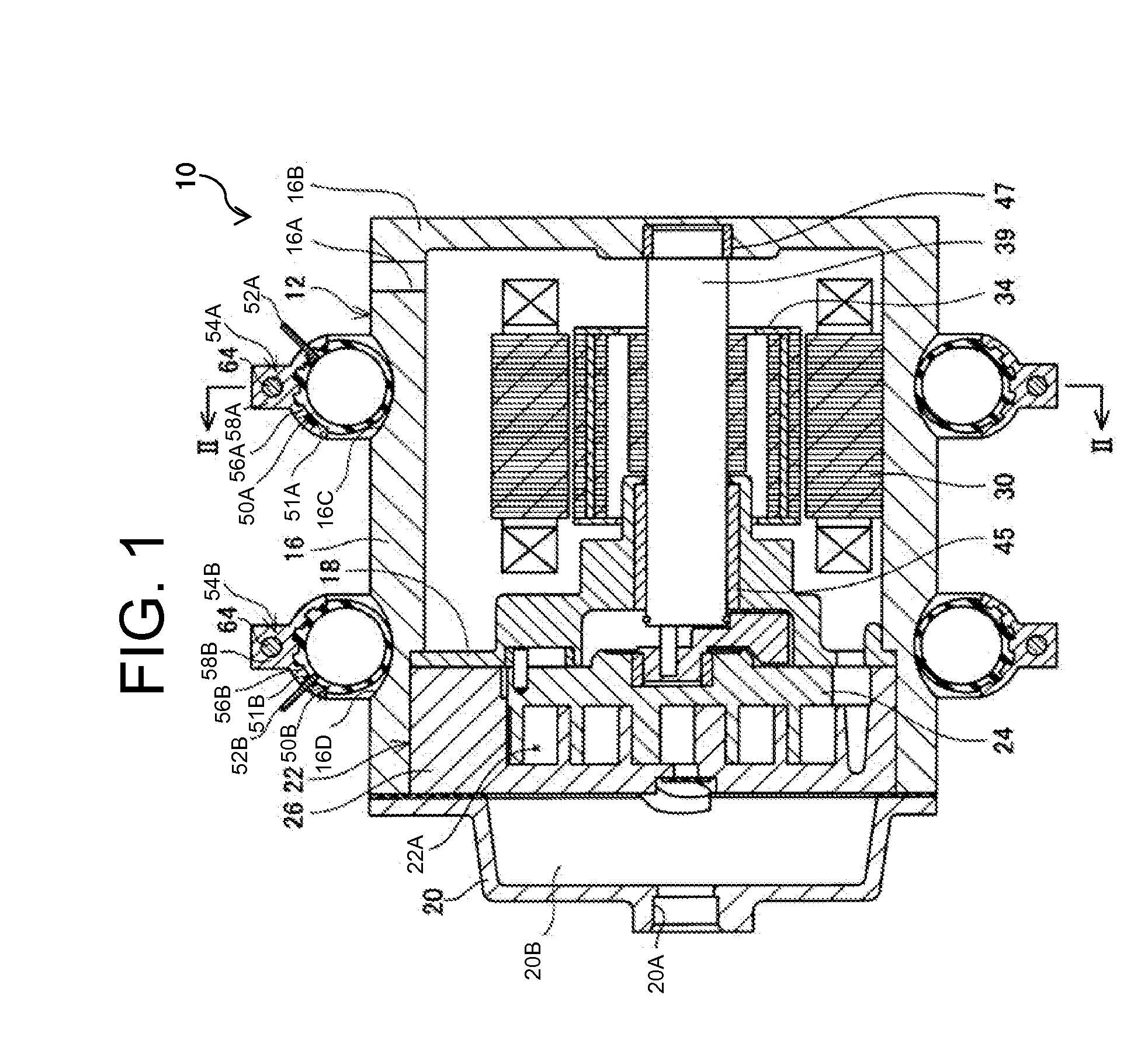

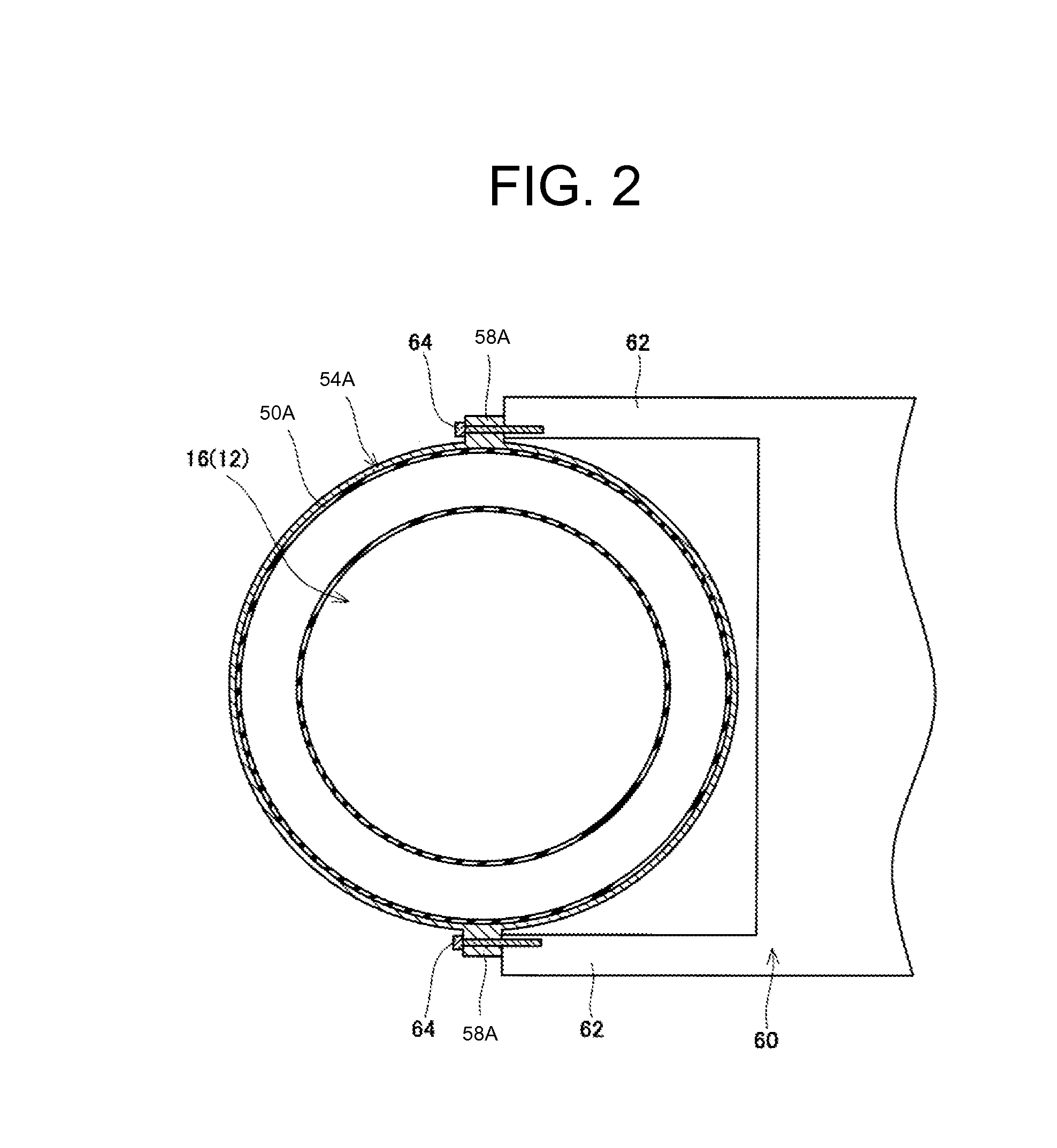

[0025]A first embodiment of the present invention will now be described with reference to FIGS. 1 to 4. An electric compressor, which is designated by numeral 10, is mounted to an electric vehicle or a hybrid car and adapted for use in a vehicle air conditioner. In FIG. 2, an engine to which the electric compressor 10 is mounted is designated by numeral 60, but in FIGS. 1, 3, and 4 the engine 60 is not illustrated. It is to be noted in the drawings some cross sections are not indicated by hatching and also that in FIG. 2 the internal configuration of a housing 12 is not illustrated. Referring to FIG. 1, the electric compressor 10 includes the housing 12 of a substantially cylindrical shape, a rotating shaft 39 that is rotatably supported in the housing 12, a motor including a stator coil 30 and a rotor 34 and a compression part 22. The motor (30, 34) and the compression part 22 are housed in the housing 12. The electric compressor further includes a pair of tubes 50A, 50B that exten...

first modification

[0044]A first modification of the present invention will now be described with reference to FIG. 5. In the following description of the first modification, only the differences form the first embodiment will be described and the detailed description on the configurations that are common to the first embodiment will be omitted. This also applies to other embodiments and modifications unless otherwise specified. It is to be noted that the internal configuration of the housing 12 is not illustrated in FIG. 5. This also applies to FIGS. 6 and 7, and FIGS. 9 to 14. In the first modification, substantially the same tube assemblies each including a tube and a rim are fitted in the respective grooves 16C, 16D of the motor housing 16. This also applies to other embodiments and modifications which will be described hereinafter.

[0045]The first modification of FIG. 5 is different from the first embodiment in the configuration of the tube. Specifically, the first modification differs from the fi...

second modification

[0047]A second modification of the present invention will now be described with reference to FIGS. 6 to 8. The second modification is different from the first modification in that two sheets 70 are added, i.e. one sheet 70 disposed between the rim 254A and the tube 150A and the other sheet 70 between the rim 254A and the tube 152A. FIG. 6 shows a state in which the air pressure of the tubes 150A, 152A is maintained within the specified range, and FIG. 7 shows a state in which some air is released from the tube 152A, so that the air pressure of the tube 152A falls below the specified range. FIG. 8A is a cross-sectional view of the tube 152A of FIG. 6, and FIG. 8B is a cross-sectional view of the tube 152A of FIG. 7. The cross sections in FIGS. 8A and 8B are taken along a plane that is perpendicular to the extending direction of the tube 152A. As shown in FIG. 6 and FIG. 8A, the sheet 70 that is disposed between the rim 254A and the tube 152A is in contact with both of the rim 254A an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com