Forming shoulder of a tubular bag packaging machine

a tubular bag and packaging machine technology, applied in the direction of packaging goods, transportation and packaging, liquid materials, etc., can solve the problems of forming shoulder wear and inability, and achieve the effect of rapid prototyping, reduced friction and therefore the required pull-off for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

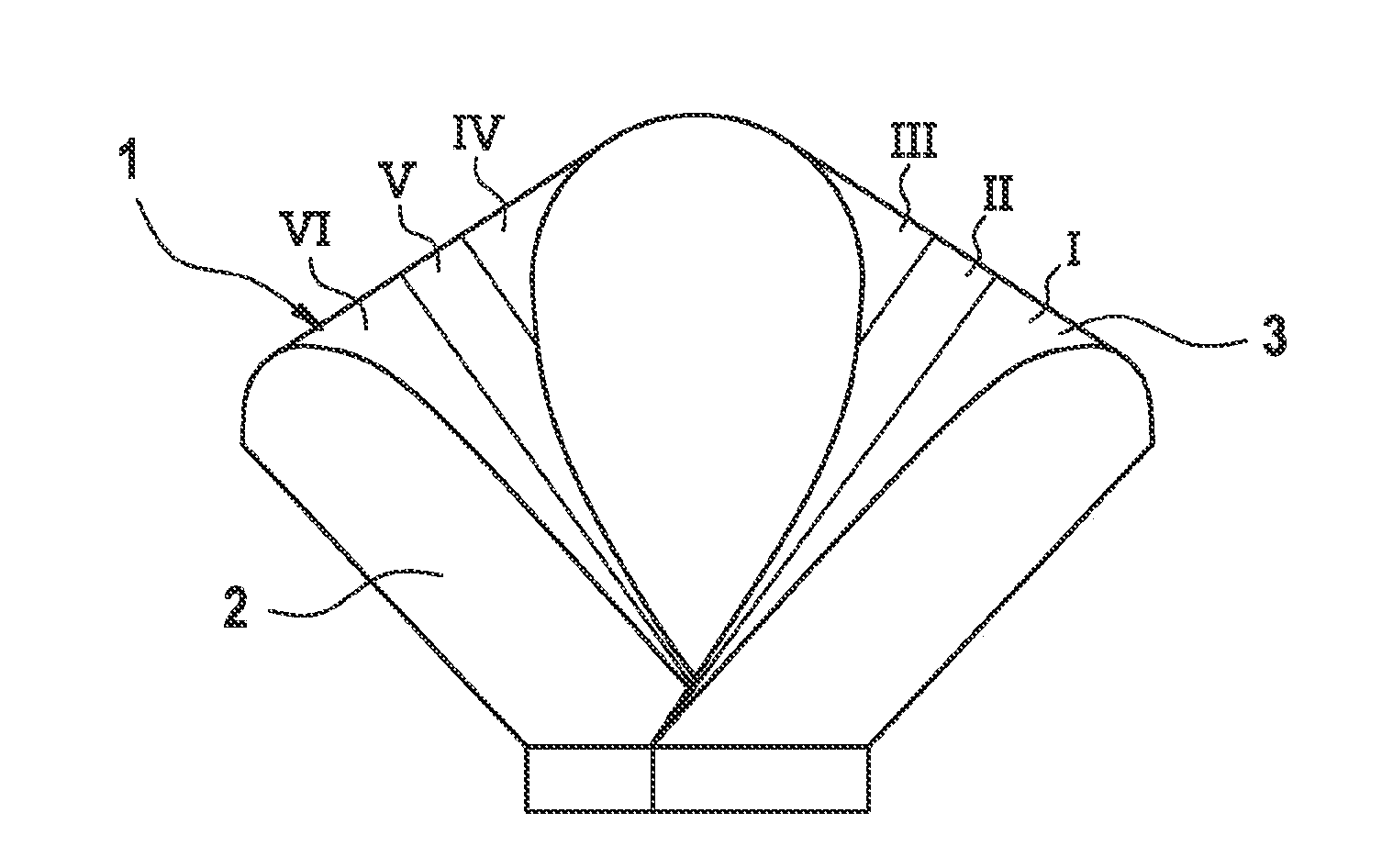

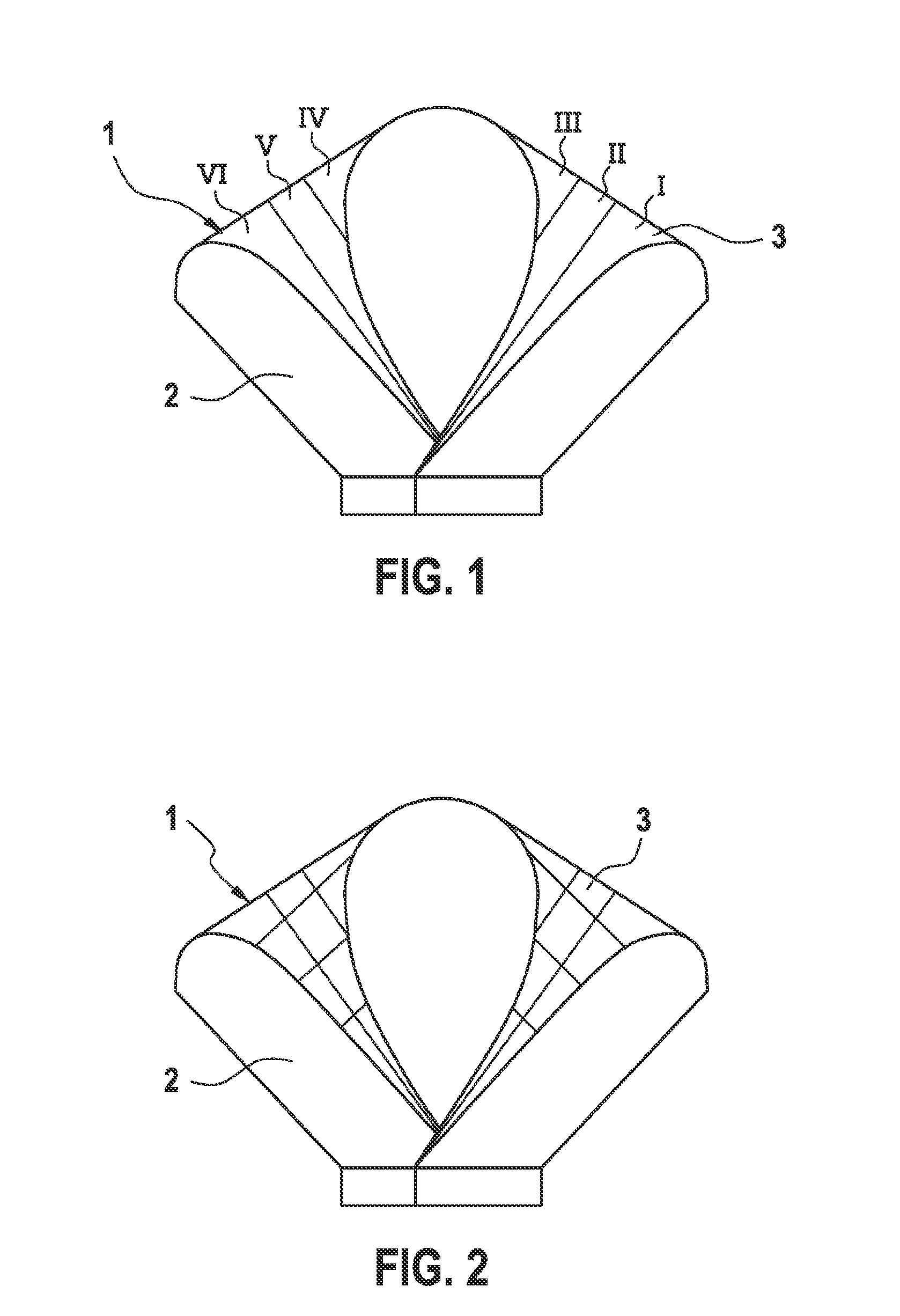

[0019]FIGS. 1 and 2 show in each case a schematic depiction of a forming shoulder according to the invention. The forming shoulder 2 depicted in FIG. 1 is designed in a segmented manner and has in total six segments Ito VI on the surface thereof, which are designed substantially strip-shaped.

[0020]In the exemplary embodiment shown in FIG. 2, the segments are designed in each case as measurement segments. This means that they are not strip-shaped but rectangular or suitably divided in order to carry out measurements over the running movement of the packaging material web, said measurements being used for the open-loop or closed-loop control of the process.

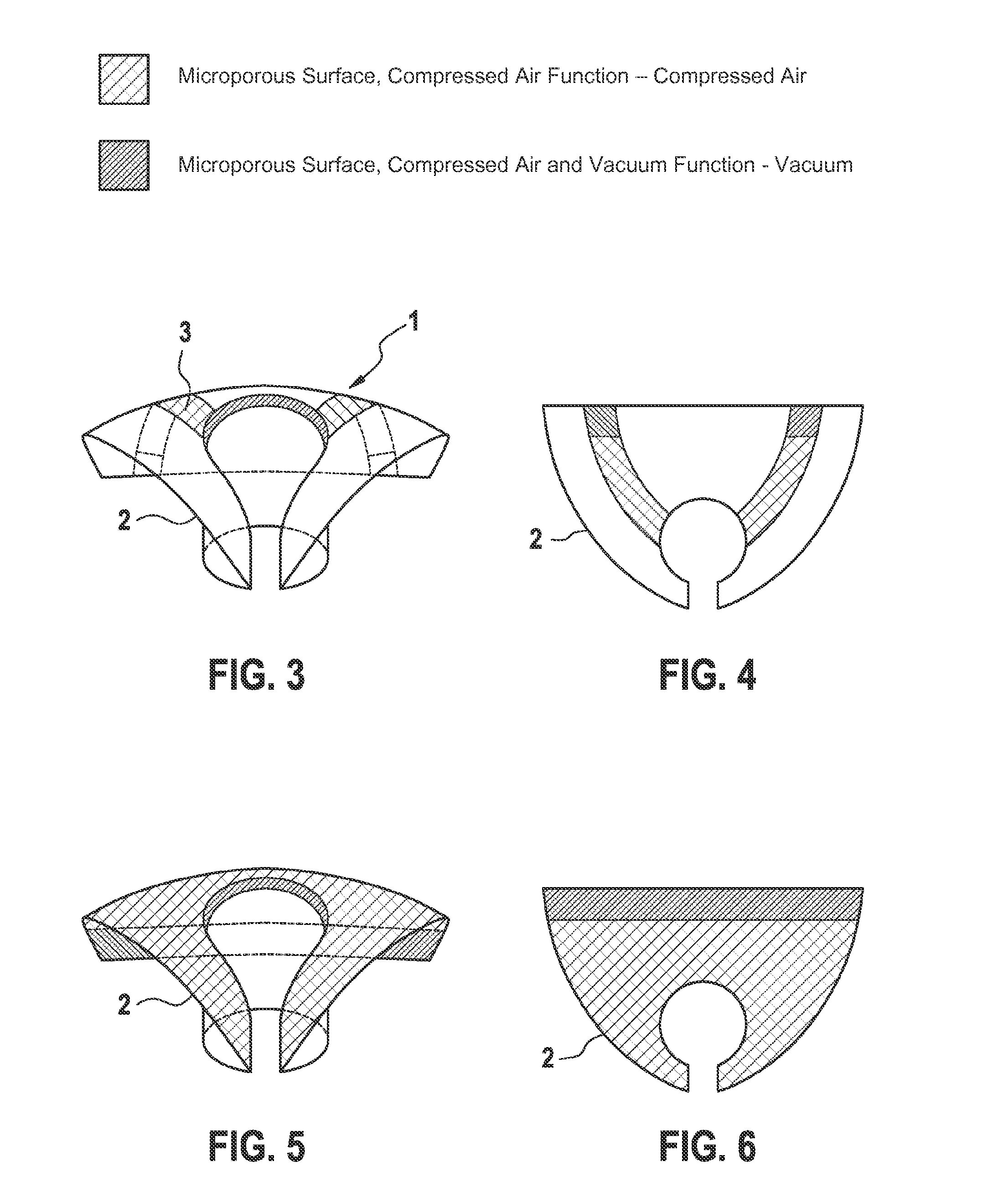

[0021]The invention thus relates, as described above, to a forming shoulder 2 which can be produced in two ways. On the one hand, production can take place by sintering and on the other hand by a generative manufacturing method, such as, for example, rapid prototyping.

[0022]The forming shoulder 2 can obtain a porous structure by mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ram pressure | aaaaa | aaaaa |

| flow resistance | aaaaa | aaaaa |

| surface properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com