Gun sight using LED illumination

a technology of led illumination and gun sight, applied in the field of devices, can solve the problems of increased difficulty in low or variable lighting conditions, reduced light output, and reduced illumination efficiency,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

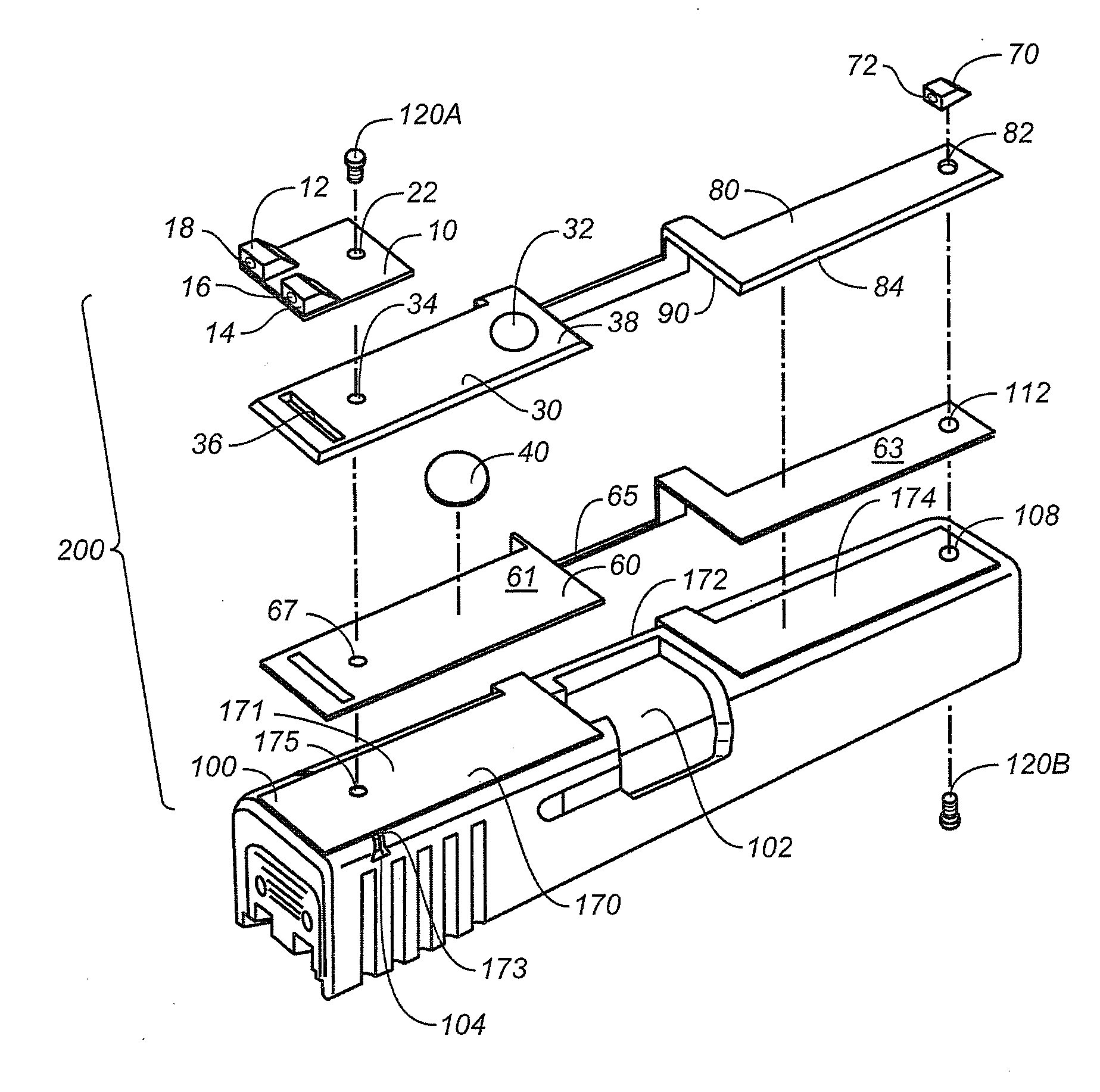

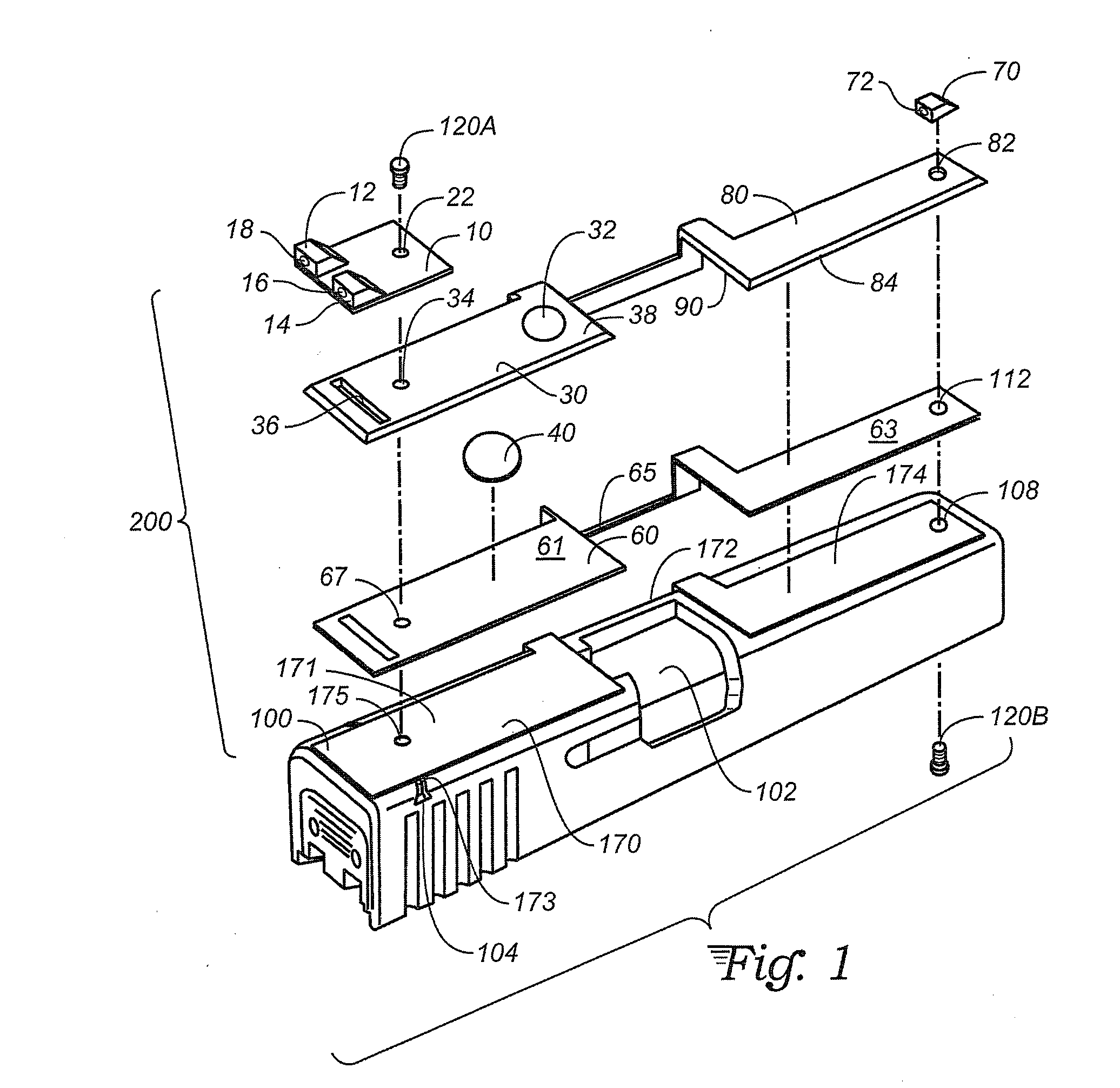

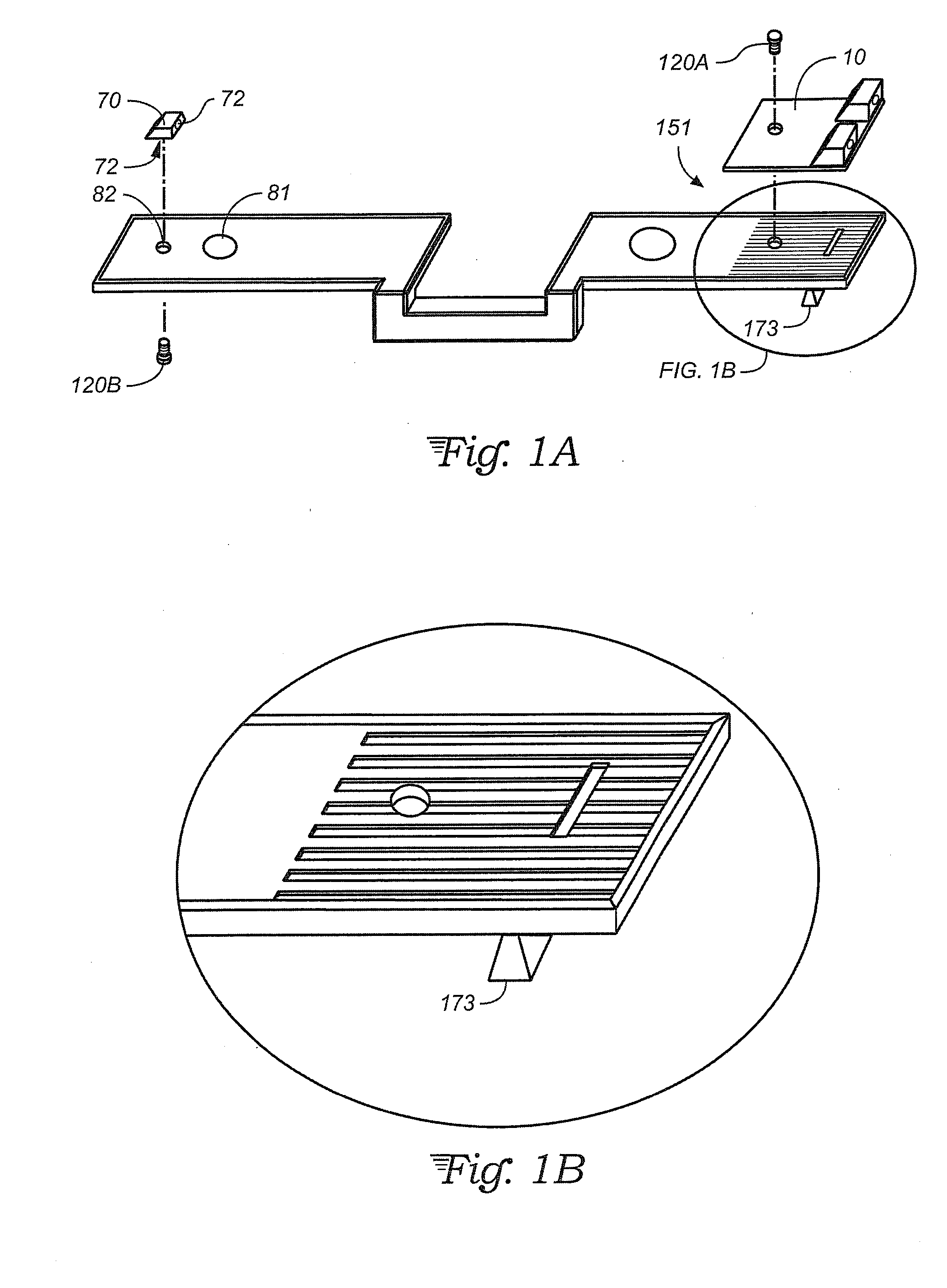

[0028]With reference to FIG. 1, an exploded view of an embodiment of the invention shows a gun slide 100. This slide is the type that may be used on a Glock® brand automatic handgun. The slide includes a central opening 102 through which shell casings are ejected after firing. A dove tail mounting slot 104 allows mounting of the stock rear sight. The stock front sight is attached using a screw 120B, through front sight mounting hole 108.

[0029]The illustrated embodiment includes a bottom housing 170 and a top housing 30 which are joined together to encase a printed circuit board 60. A detail view of the printed circuit board is shown at FIG. 1C. The bottom housing 170 and top housing 30 may be made of high impact plastic. Bottom housing 170 has a underside adhesive 176. This may be an adhesive that includes a release liner adhering to the adhesive layer. The release liner could be removed and the device mounted on a gun. The adhesive would then cure, providing a firm attachment to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com