Shape Memory Safety Utensil

a memory safety and utensil technology, applied in the field of utensils, can solve the problems of serious burns on the inside of the mouth of a person, children and elderly people often cannot or do not recognize such indications,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

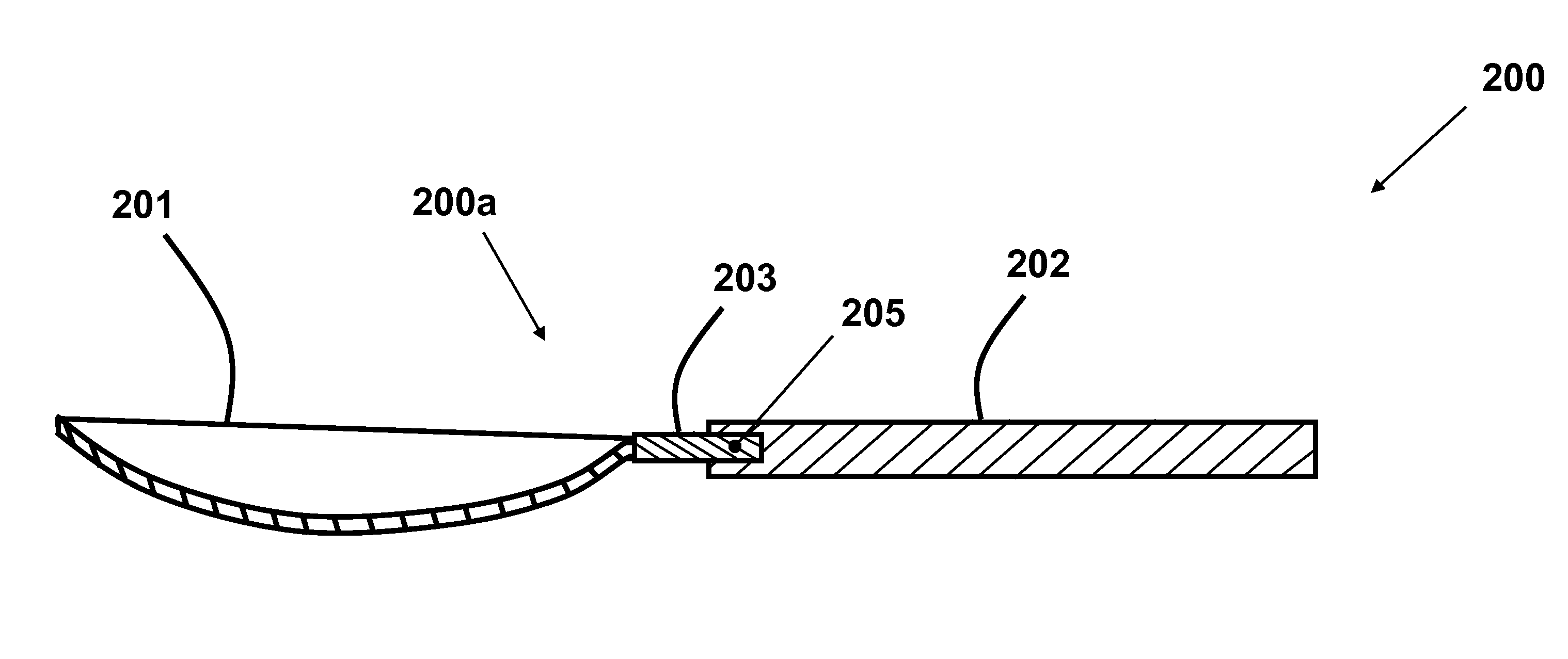

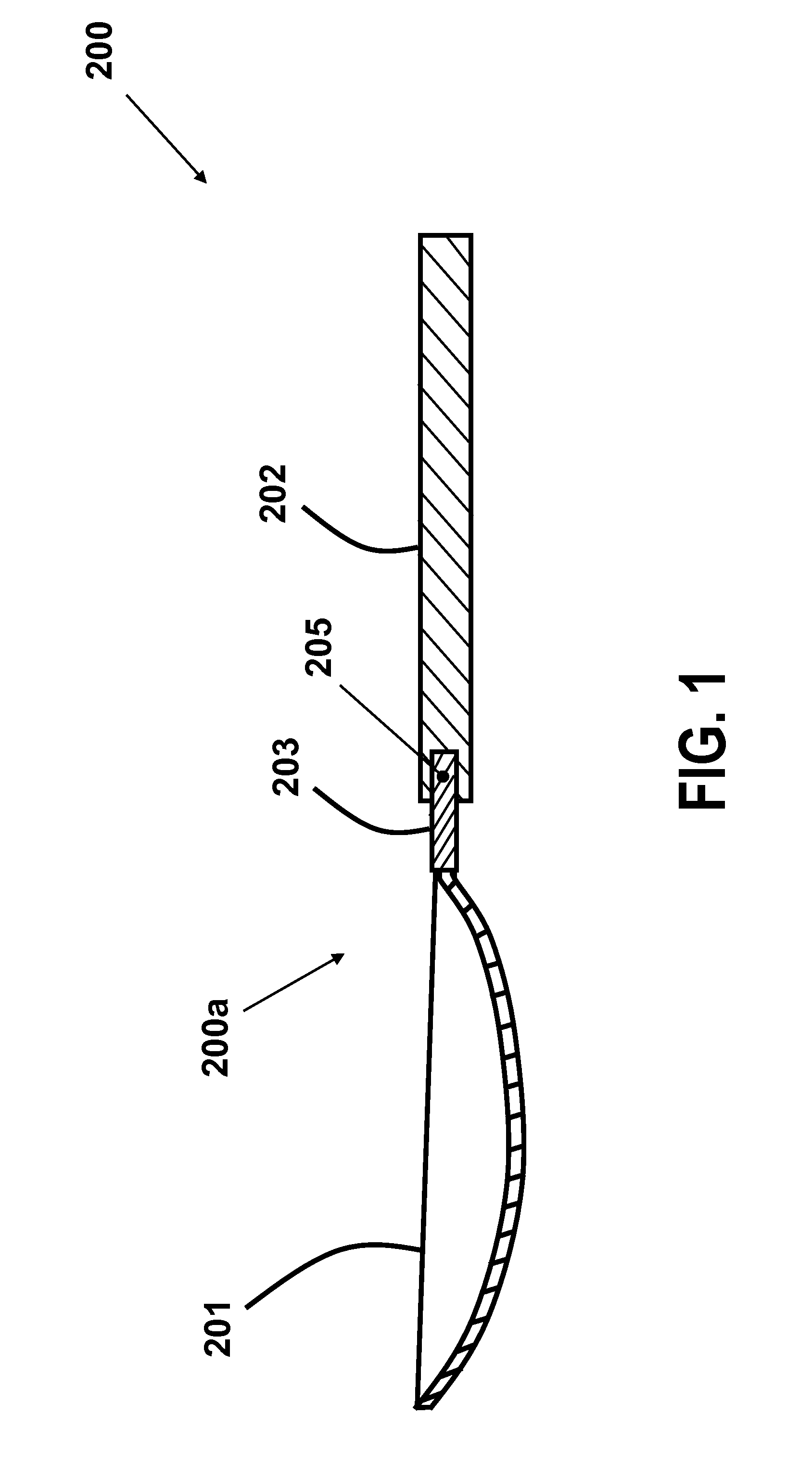

embodiment 200

[0036]A top view of a first variation of the embodiment 200 of FIG. 1 is shown in FIG. 3A. In this variation, the shape memory alloy neck portion 203a is shown to be constructed with a relatively thin strip of shape memory alloy material which is connected to the concave portion 201 on one end such as by welding, brazing or the like and is fixed to the spoon handle 202 on the other end, with the handle being an appropriate food grade plastic that is molded over the end portion 205a as shown in FIG. 3A.

[0037]Alternatively, as shown in the top view of FIG. 3B of a second variation of the embodiment 200 of FIG. 1, at least one shape memory alloy neck portion 203b configured as a wire is used to connect the concave portion 201 to the spoon handle 202. The handle 202 can be made out of an appropriate food grade plastic that is molded over the end portion 205b of the at least one shape memory alloy “wire” neck portion 206.

[0038]The shape memory alloy wires (of round, square or other shape...

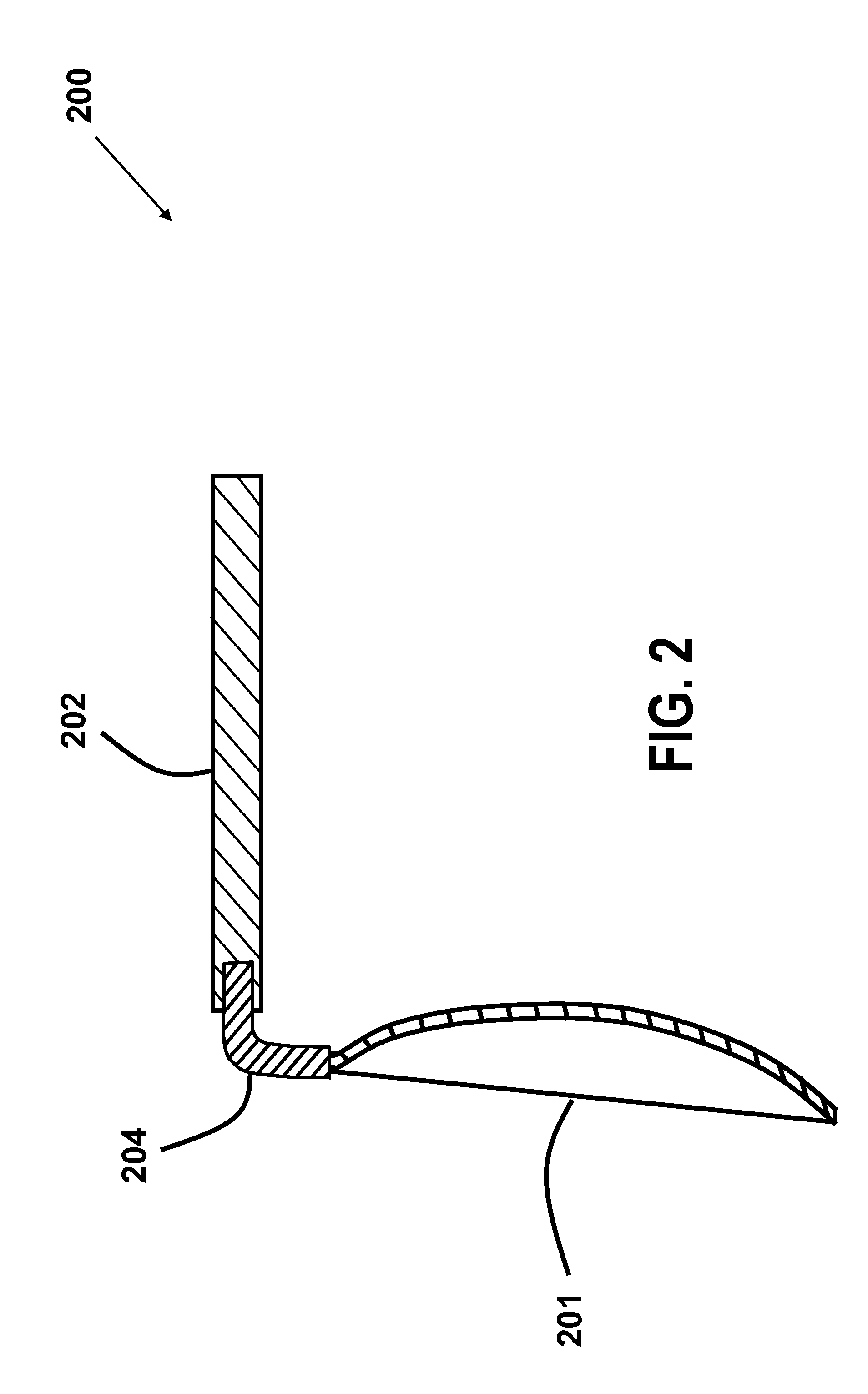

embodiment 220

[0040]In an alternative embodiment 220 shown in FIG. 4, a distance between a center region 221 of the concave portion 201 and the shape memory alloy neck portion 222 connecting the concave portion 201 to the spoon handle 202 may be reduced to allow for its rapid heating to the aforementioned transition temperature and its consequent deformation, for example to the configuration 223 shown in the schematic of FIG. 5. In the alternative embodiment 220, the frontal section 224 (FIGS. 4 and 5) of the shape memory alloy neck portion 222 is attached close to the mid-section of the bottom side of the concave portion 201. However, other portions of the shape memory alloy neck portion 222 can still contact the concave portion 201 while not being fixedly connected. As a result, heat is transferred rapidly from the hot food inside the spoon, but more importantly, as the user brings the spoon in contact with food, the regions around the sections 224 and 225 of the shape memory alloy neck portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com