Heater Having Heating Core and Conductive Fin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

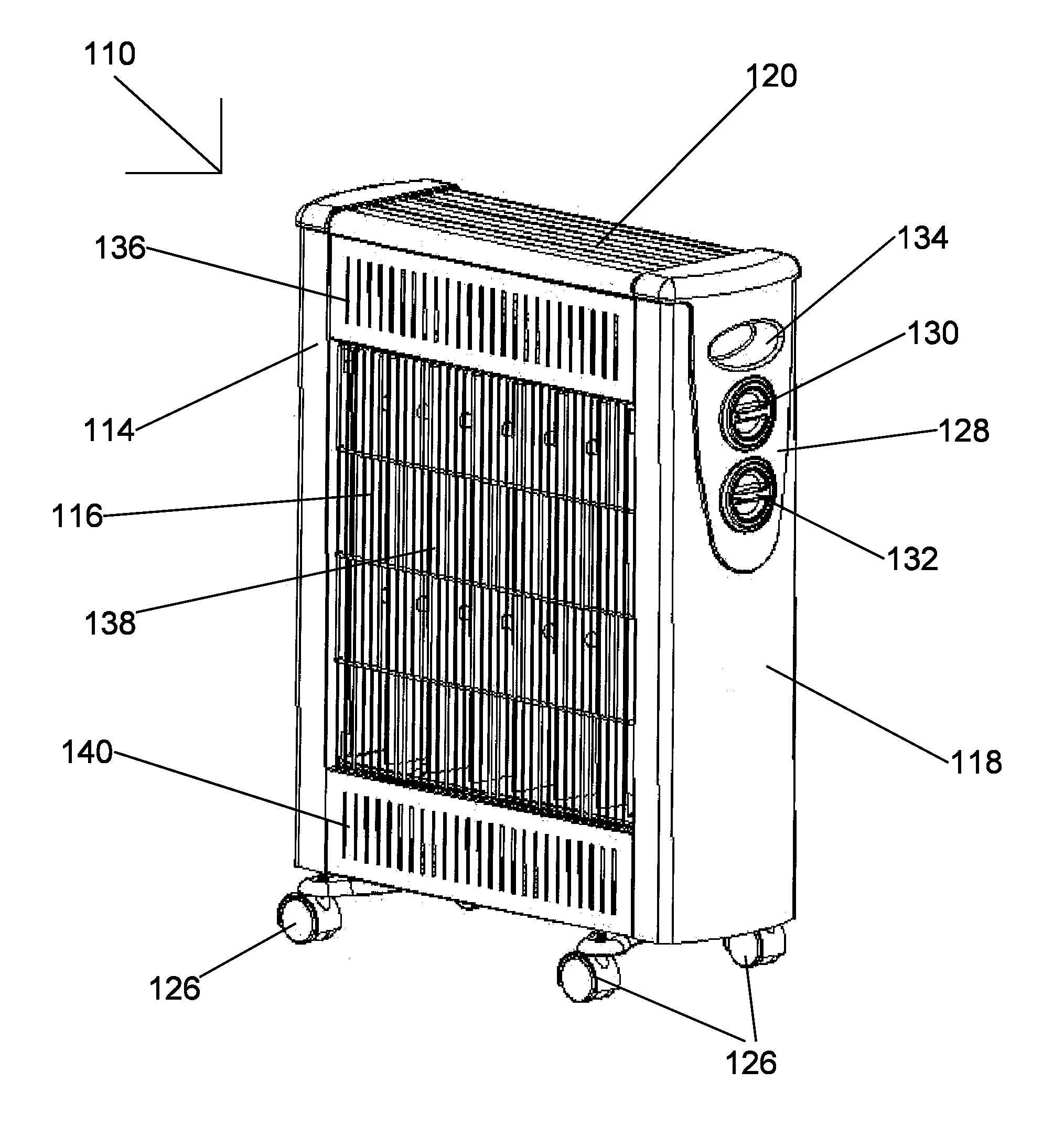

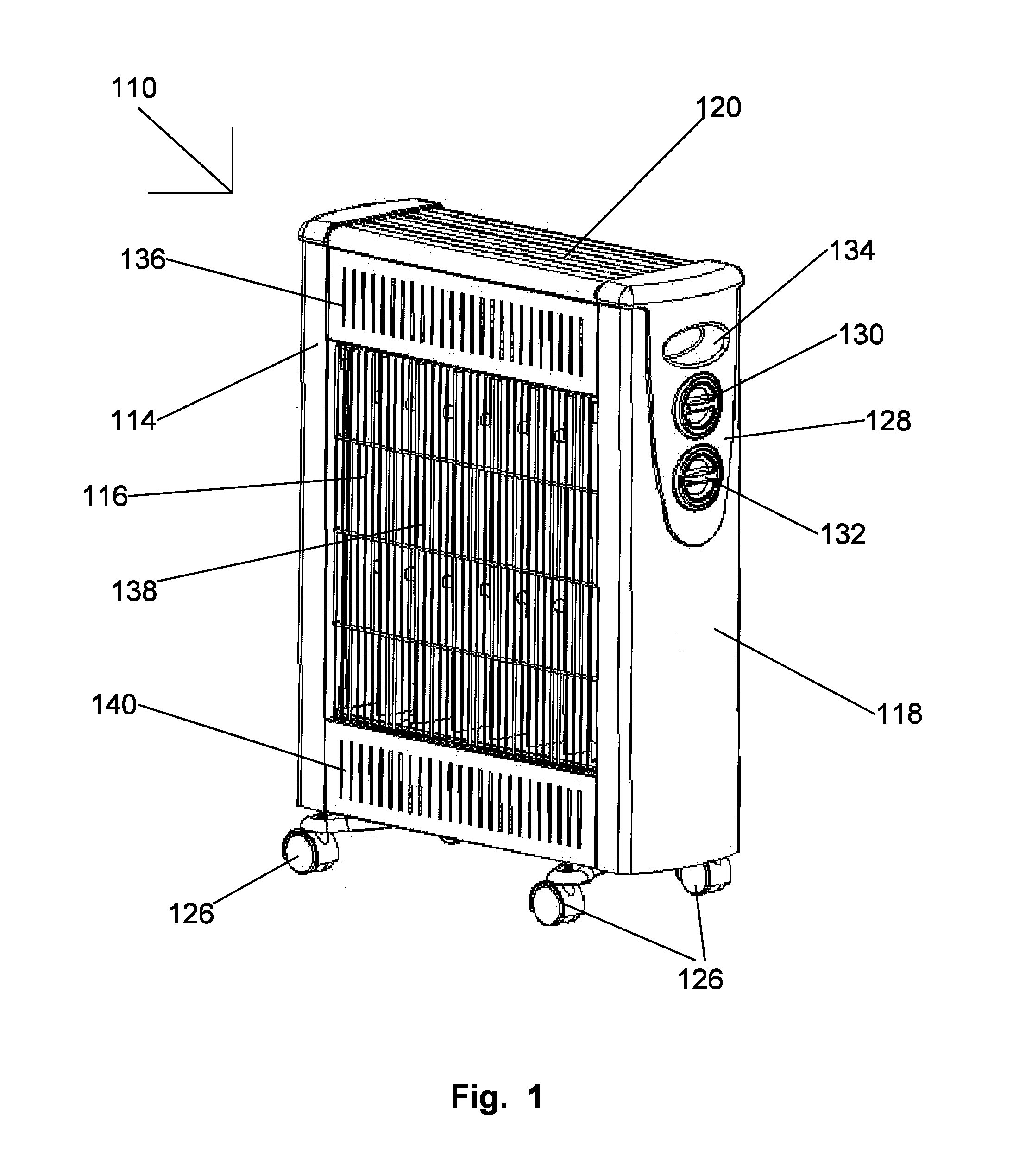

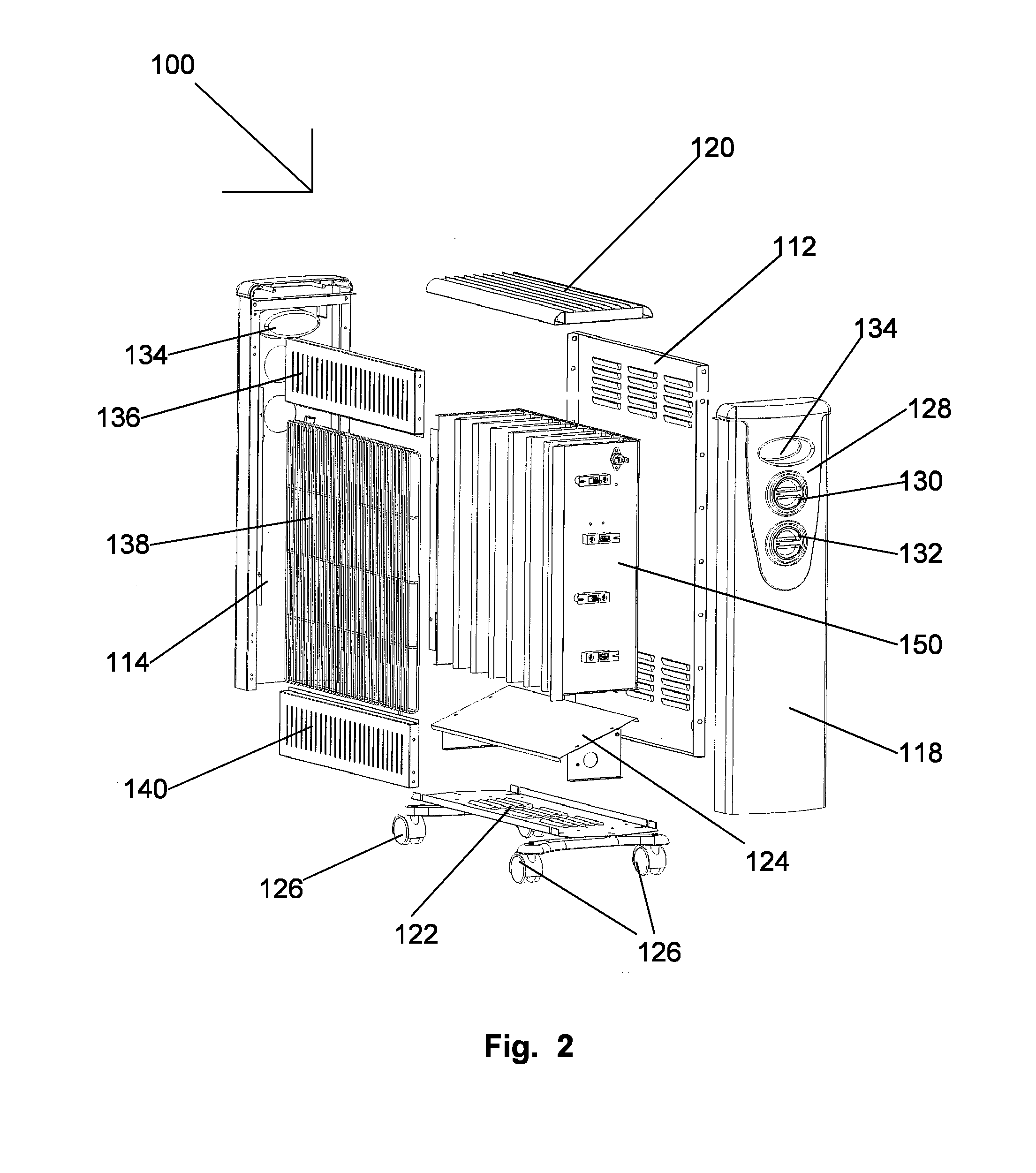

[0070]In reference to the claims and diagrams, the following detailed description is provided.

[0071]It is thus one aspect, embodiment, objective and advantage of the present invention to provide a heating core for a heater, said heating core comprising: a corrugated heat conductive fin; a first side panel attached to a first end of said fin; a second side panel attached to a second end of said fin; and at least one heating element mounted to and extending between said first and second side panels; wherein said fin is self-supporting between said first and second side panels.

[0072]It is thus another aspect, embodiment, objective and advantage of the present invention to provide a heating core for a heater, further comprising an additional third panel attached to said first and second side panels, with a space between said additional third panel and said fin.

[0073]It is thus another aspect, embodiment, objective and advantage of the present invention to provide a heating core for a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com