Furniture article with concealed storage and removable panels

a technology of furniture articles and panels, applied in the field of ready-to-assemble modular furnishings, can solve the problems of difficult and counterintuitive assembly, extensive use of composite materials clad with high-pressure decorative laminates, and art ready-to-assemble furnishings, and achieve the effect of resisting the disassembly of tab and slot joinery and minimizing the appearance of joinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

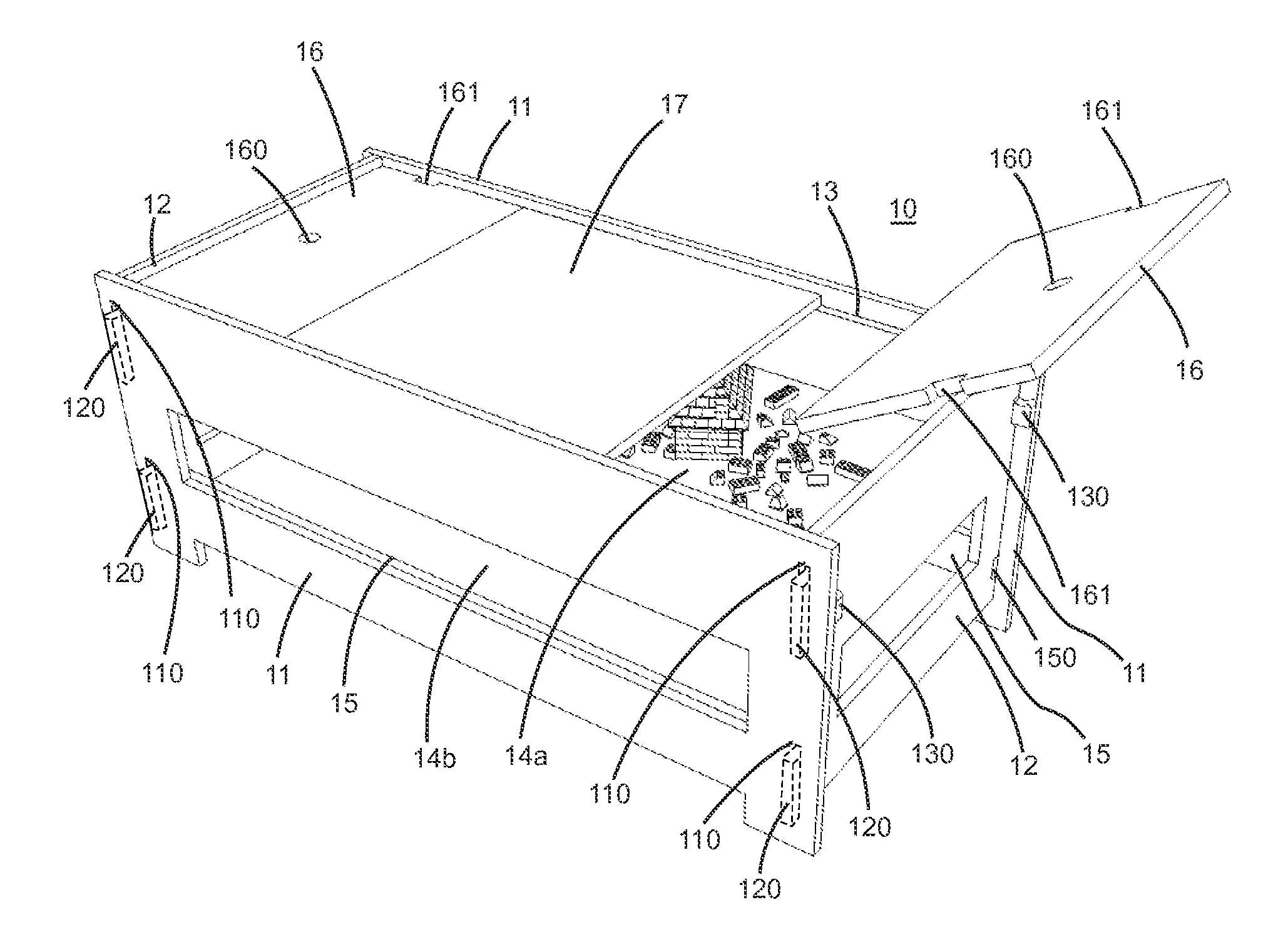

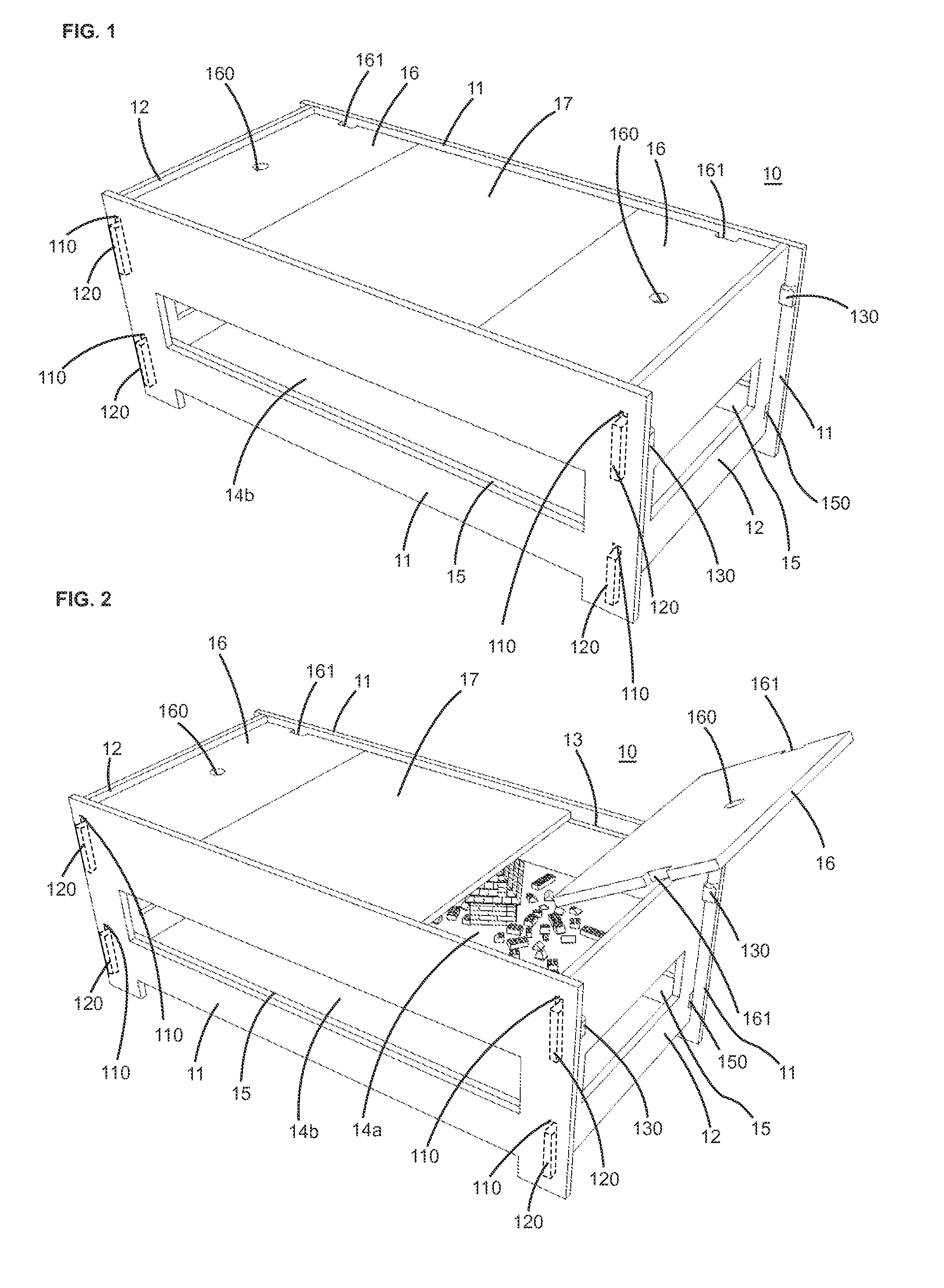

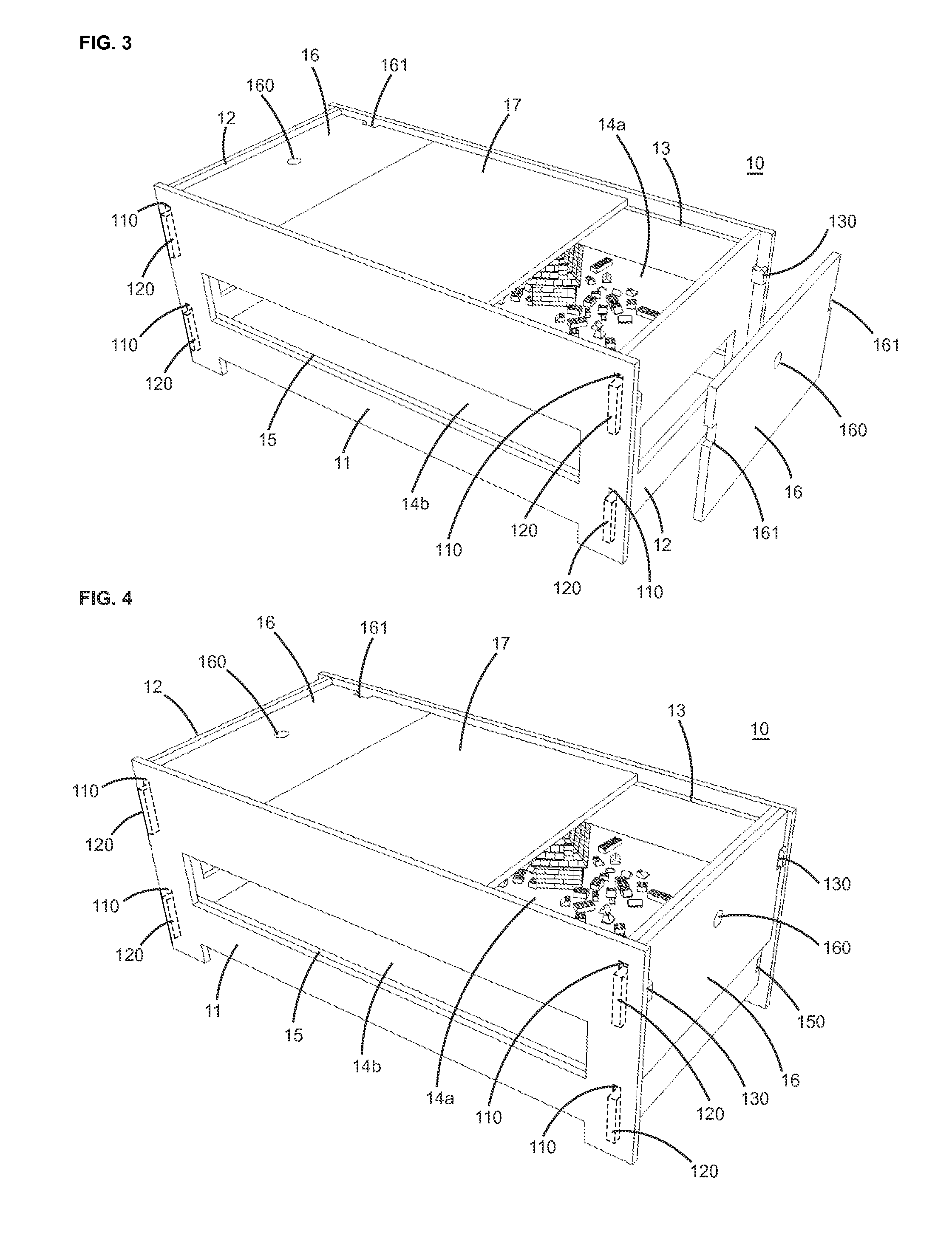

[0035]Referring to FIGS. 1-5 in the drawings, a children's play table 10, made in accordance with the modular furniture system of the present invention, is illustrated. The play table 10 is an example of the type of ready-to-assemble furniture that can be fit together from interlocking panels using corresponding slot and tab elements without need for tools or fasteners. As explained herein, the modular furniture system allows a user to assemble, disassemble, and reconfigure a complementary arrangement of exterior and interior panels that hide the joinery formed by the slot and tab elements, while creating a large variety of aesthetically pleasing furnishings that also provide concealed storage areas. Furnishings assembled from the interchangeable and reversible components of the present invention are ideally suited for use where storage space is limited, and may include pieces such as tables, desks, cribs, mattress foundations, and other items.

[0036]As illustrated in FIGS. 1-5, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| right angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com