Non-Adjustable Pointer-Tracker Gimbal Used For Directed Infrared Countermeasures Systems

a pointer-tracker gimbal and infrared countermeasure technology, applied in the direction of direction/deviation determining electromagnetic systems, instruments, angle measurement, etc., can solve the problem of not being able to easily compensate for positional errors of mirrors, not being able to adjust for all pointing directions, and complicating the situation of locking the adjustment mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

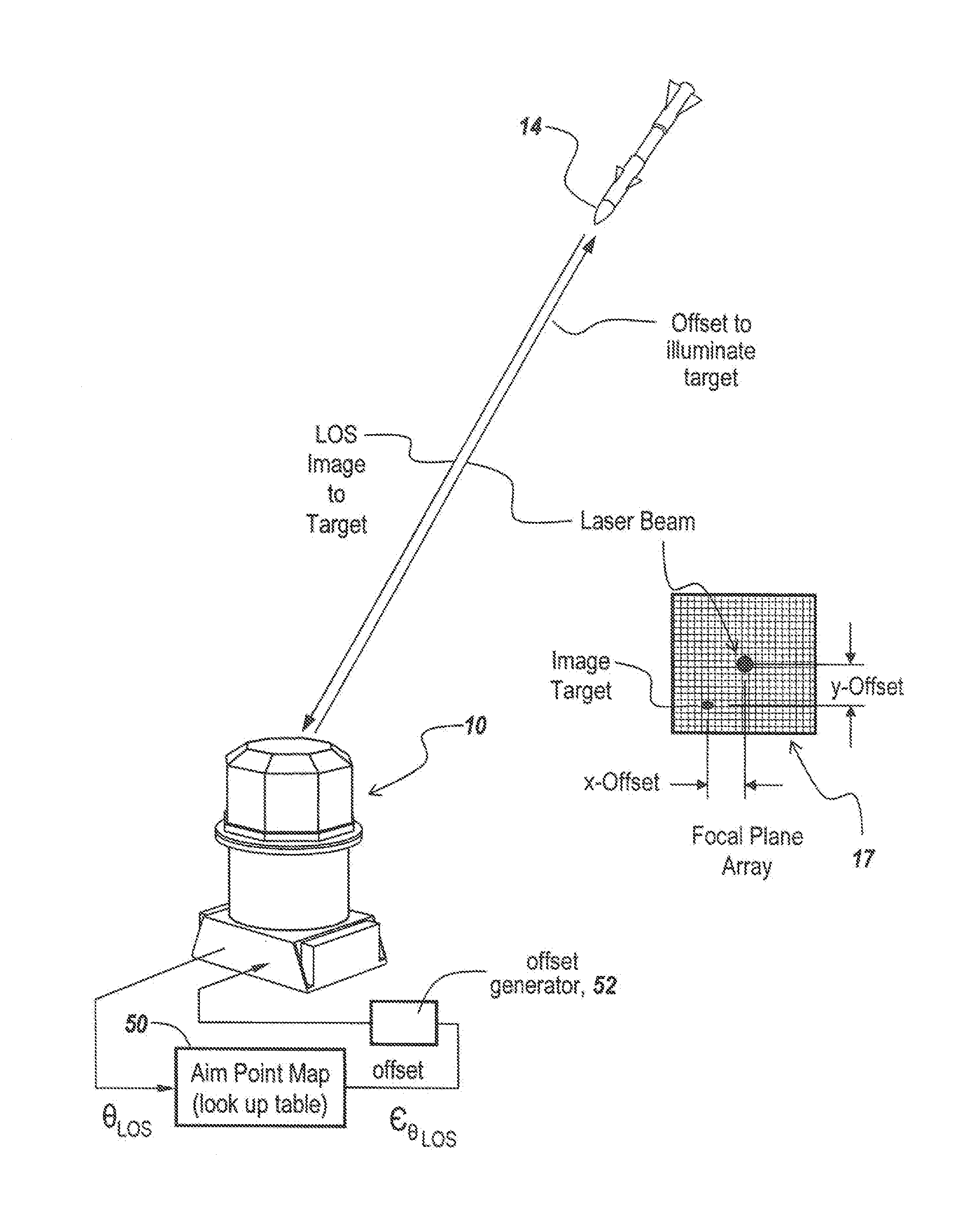

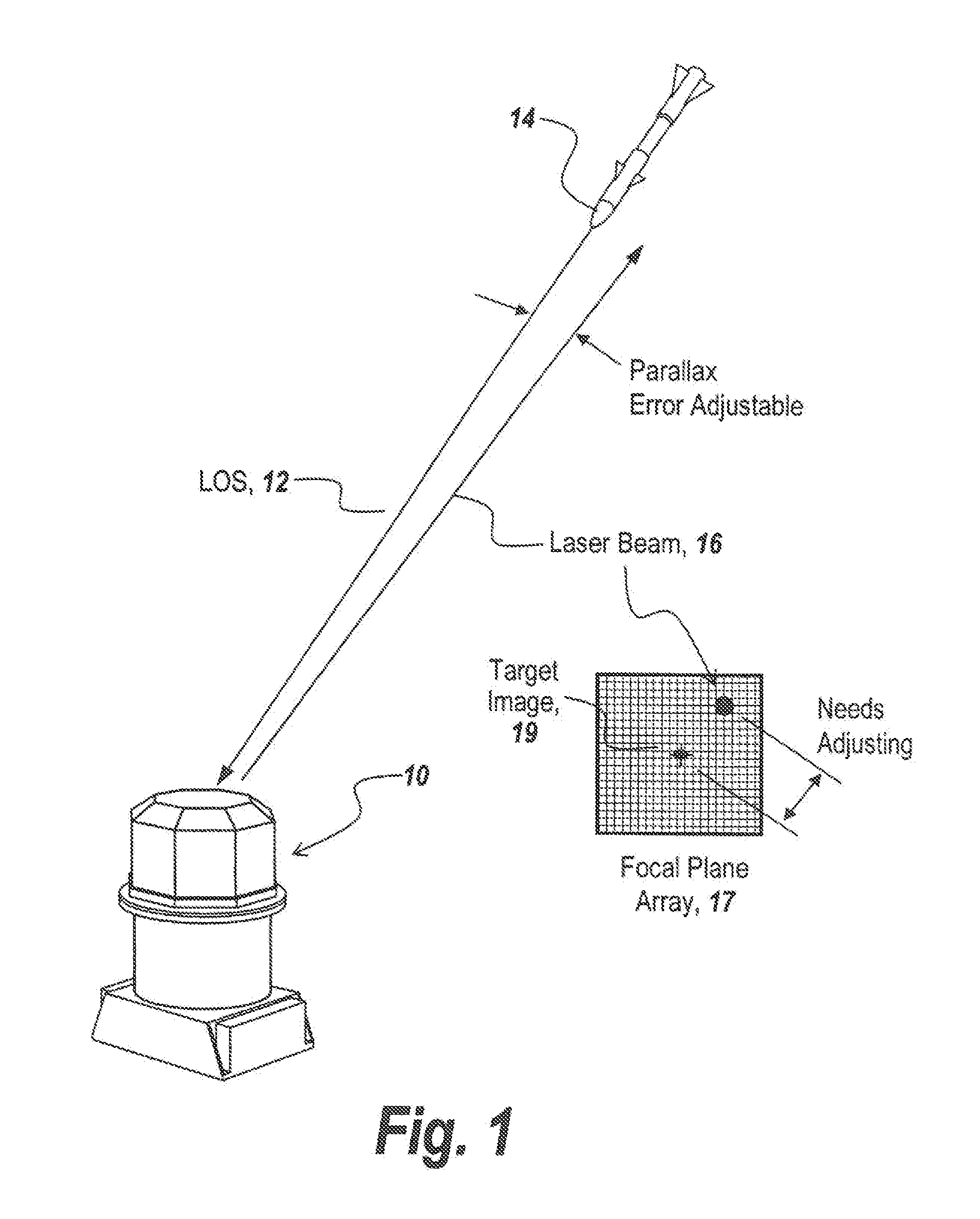

[0039]Referring now to FIG. 1, a pointer-tracker gimbal 10 is utilized to detect the line-of-sight 12 to a target 14 and aim a laser beam 16 towards the head of the missile.

[0040]Pointing accuracies required for such pointer-trackers are substantial. The pointing accuracies required to assure a hit on the target must be less than the total errors within the system, namely in one embodiment a 200 microradian divergence between the line-of-sight to the target and the projected laser beam. As illustrated, the laser beam path 16 and the line-of-sight to the true target 14 must be brought into alignment as would be the case with a coincidence of the back projection of the laser 16 beam with target image 19 on focal plane array 17. This is done by adjustments that must be maintained during the harsh environment of military aircraft.

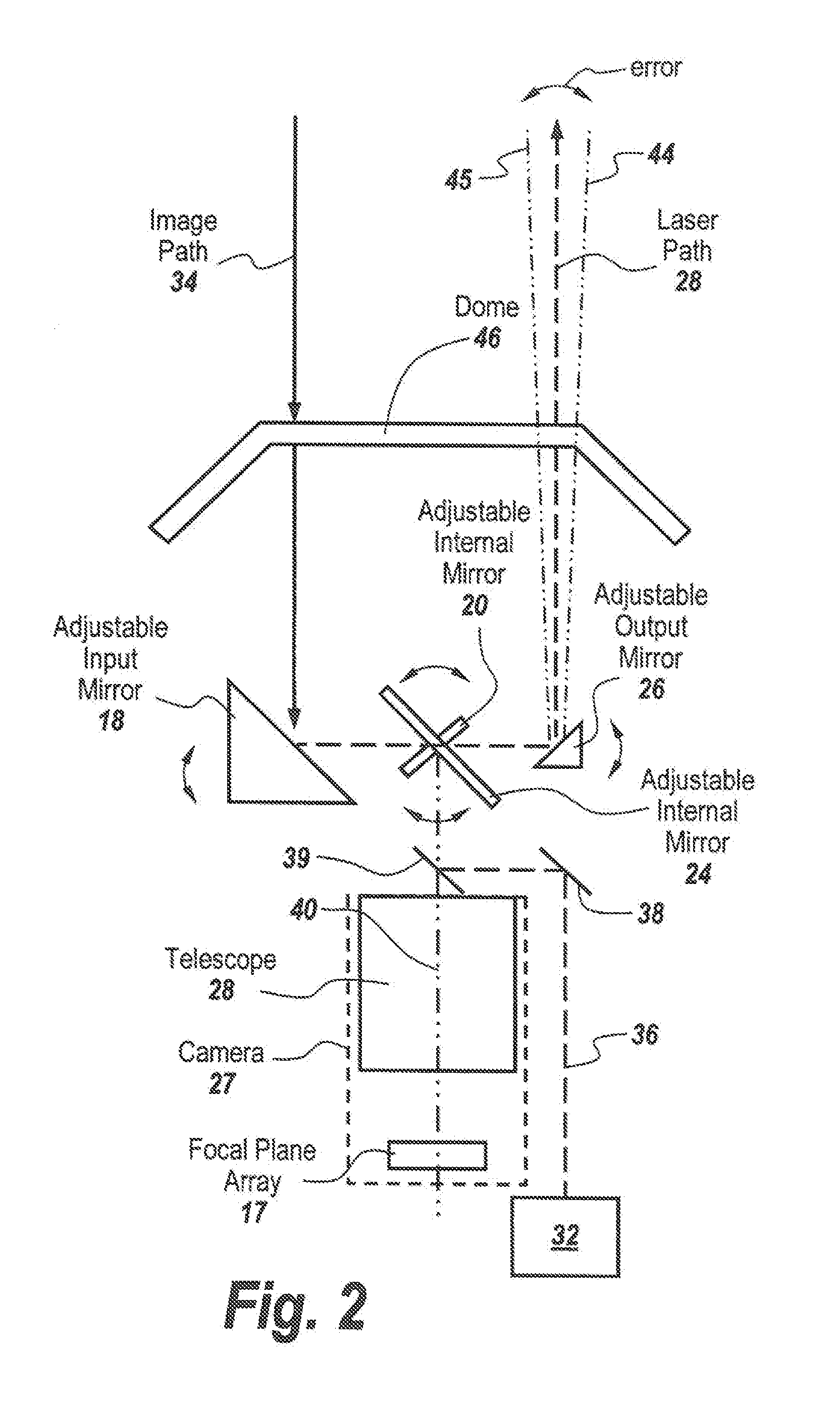

[0041]This stringent requirement in and of itself is extremely difficult to achieve and as shown in FIG. 2, gimbals require individually adjustable mirrors, na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com