Three-axis ois for super-resolution imaging

a three-axis ois and super-resolution technology, applied in the field of image resolution enhancement techniques, can solve the problems of affecting the hardware requirements of miniature cameras such as those found on mobile devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

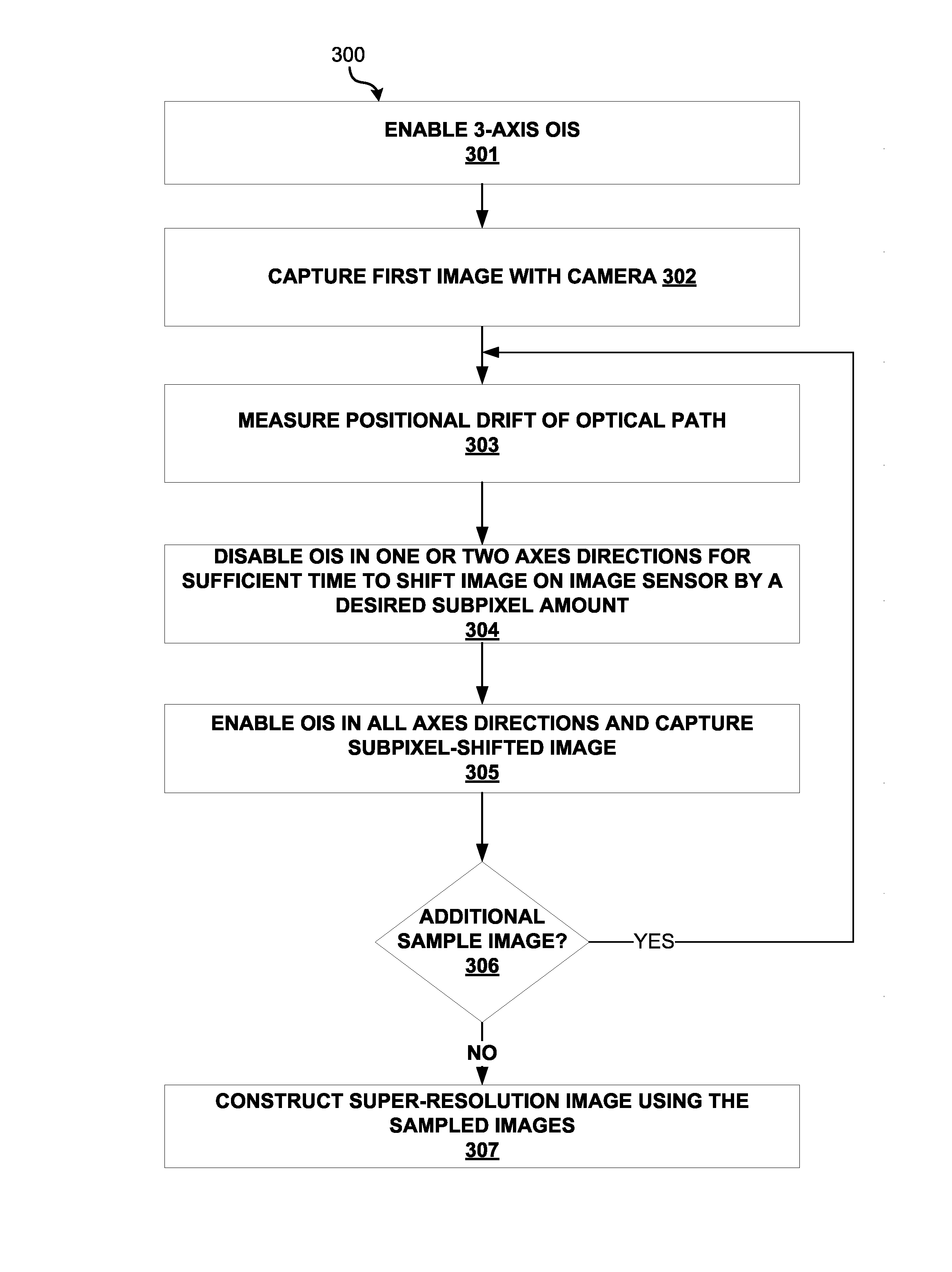

[0030]There are two problems with current implementations of super-resolution imaging techniques in handheld mobile devices that prevent accurate capture of subpixel shifts of a reference picture. First, such implementations rely on 2-axis OIS systems that fail to correct the roll of the imaging device during image capture. However, a 2-axis (pitch and roll) OIS of the image fails to stabilize / compensate for the roll direction of the camera. Thus, the optical path to the image sensor is not completely stabilized and there is motion blur from the variations of the rotation aperture. This motion blur is particularly pronounced along the edges of the image where there is the greatest variability in the rotation aperture. Thus, pitch and yaw (2-axis) OIS-based techniques cannot be used to effectively stabilize an image to less than one pixel in handheld mobile devices.

[0031]Second, current implementations rely on the OIS itself to effectuate specific subpixel movements of the camera len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com