Fire sprinkler with flue-penetrating non-circular spray pattern

a fire sprinkler and spray pattern technology, applied in the field of fire sprinklers, can solve the problems of increasing the cost of an installed fire suppression system, affecting the safety of personnel, so as to reduce the number of supply lines, reduce the volume, and reduce the effect of pressure and volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

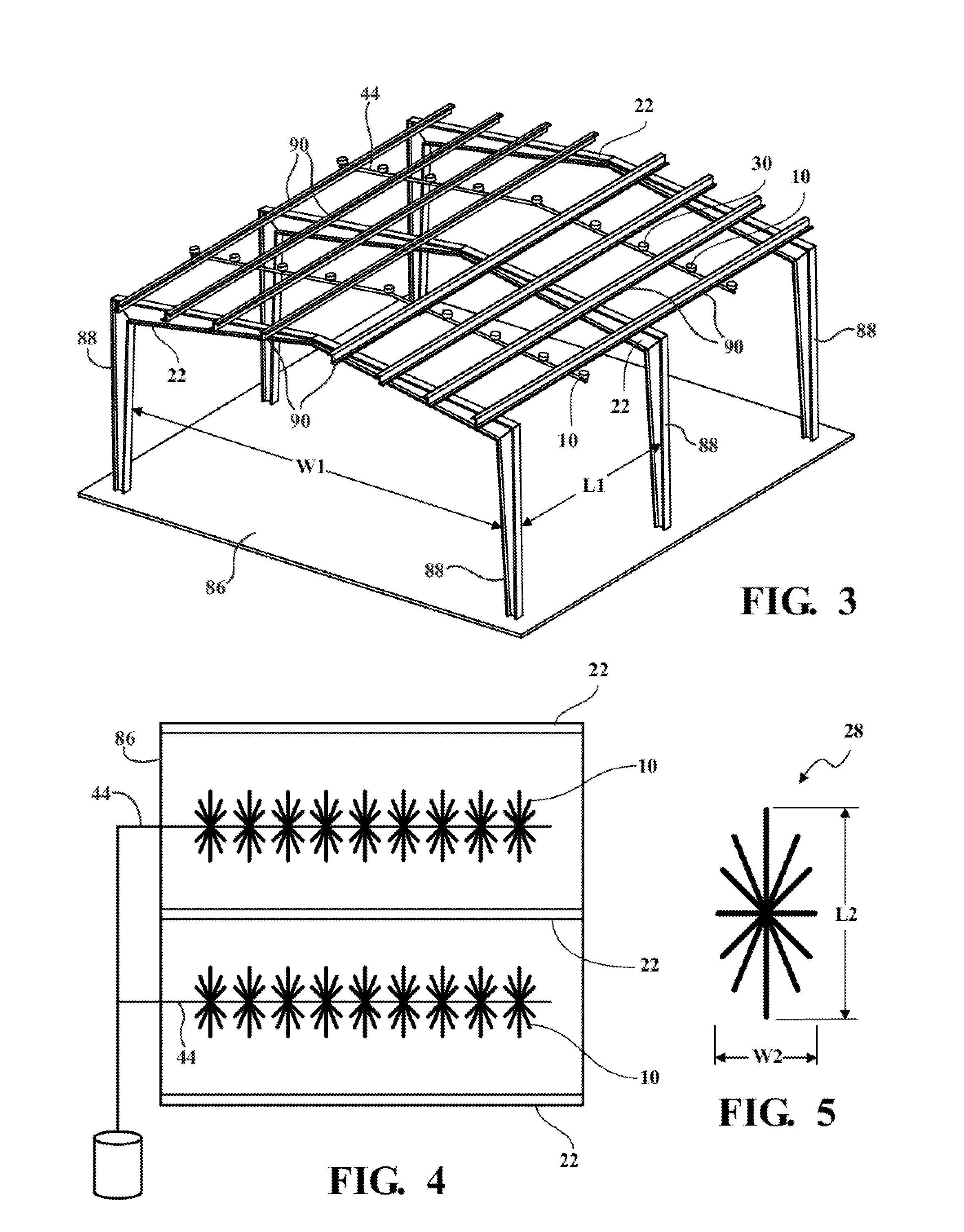

[0081]A sprinkler head 42 has a coverage area 28 with a twenty-five foot major diameter (L2) and an eight foot minor diameter (W2). The k-factor is k=17. At a steady 52 psi line pressure, this sprinkler head 42 will distribute approximately 122.58 gpm.

example 2

[0082]A sprinkler head 42 has a coverage area 28 with a twenty-five foot major diameter (L2) and a four foot minor diameter (W2). The k-factor is k=11. At a steady 35 psi line pressure, this sprinkler head 42 will distribute approximately 65.07 gpm.

[0083]In Example 1, it may be presumed that only one fire sprinkler 42 will activate because of the greater spacing (six-to-eight feet) between adjacent spray heads 42. This single activated spray head 42, fed by 52 psi line pressure, will deliver approximately 122.58 gpm onto the fire. However, in Example 2, it may be presumed that two fire sprinklers 42 will concurrently activate because of the closer spacing (four-to-five feet) between adjacent spray heads 42. These two activated spray heads 42, fed by a modest 35 psi line pressure, will combine deliver approximately 130.15 gpm onto the fire. Thus, two spray heads 42 operating at lower supply line 44 pressure can deliver water at a greater rate onto a fire than can a single spray head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com