Sewn ball and manufacturing method thereof

a technology of sewing ball and ball, applied in the field of sewing ball, can solve the problems of poor flight balance, hard ball and easy hitting of hands, and inability to stabilize flight, and achieve the effects of good durability, excellent jumping ability, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

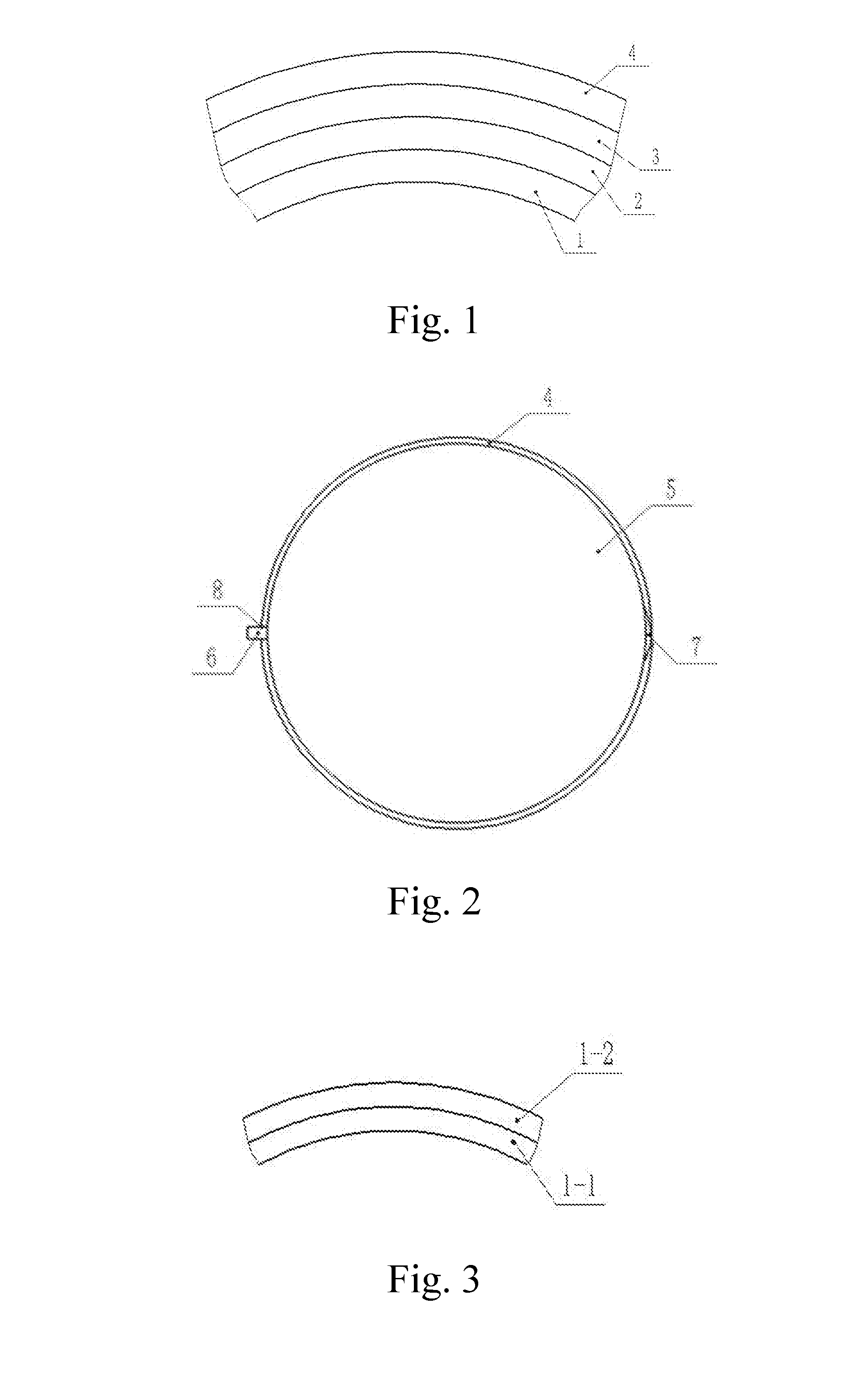

[0047]Referring to the drawing, a sewn ball is illustrated, comprising an inner tube 5 and a housing 4, wherein the inner tube 5 comprises a tube body 1, a yarn layer 2 and a rubber layer 3, wherein the yarn layer 2 is attached to an external surface of the tube body 1; the rubber layer 3 is attached to an external surface of the yarn layer 2 and is then vulcanized, in such a manner that a rubber raw material of the rubber layer 3 permeates through the yarn layer 2, so as to integrate the tube body 1, the yarn layer 2 with the rubber layer 3; and the housing wraps around and is attached to the inner tube 5.

embodiment 2

[0048]If the thicker yarn layer 2 winds around the tube body 1, a surface of the manufactured inner tube 5 is harder, so that a jumping ability of a ball is affected; and meanwhile, if the thinner yarn layer 2 winds around the tube body 1, the yarn layer 2 is unable to sufficiently bind up the tube body 1, so that the inner tube 5 has low strength, poor damage resistance and is not durable. To avoid the above situations, preferably, a thickness of the yarn layer 2 is 0.1-1 mm. Under a premise of guaranteeing an enough restraint of the yarn layer 2 to the tube body 1, the thickness of the yarn layer 2 is properly selected for improving the strength of the inner tube 5, and simultaneously giving consideration to both the surface hardness and the jumping ability of the ball.

embodiment 3

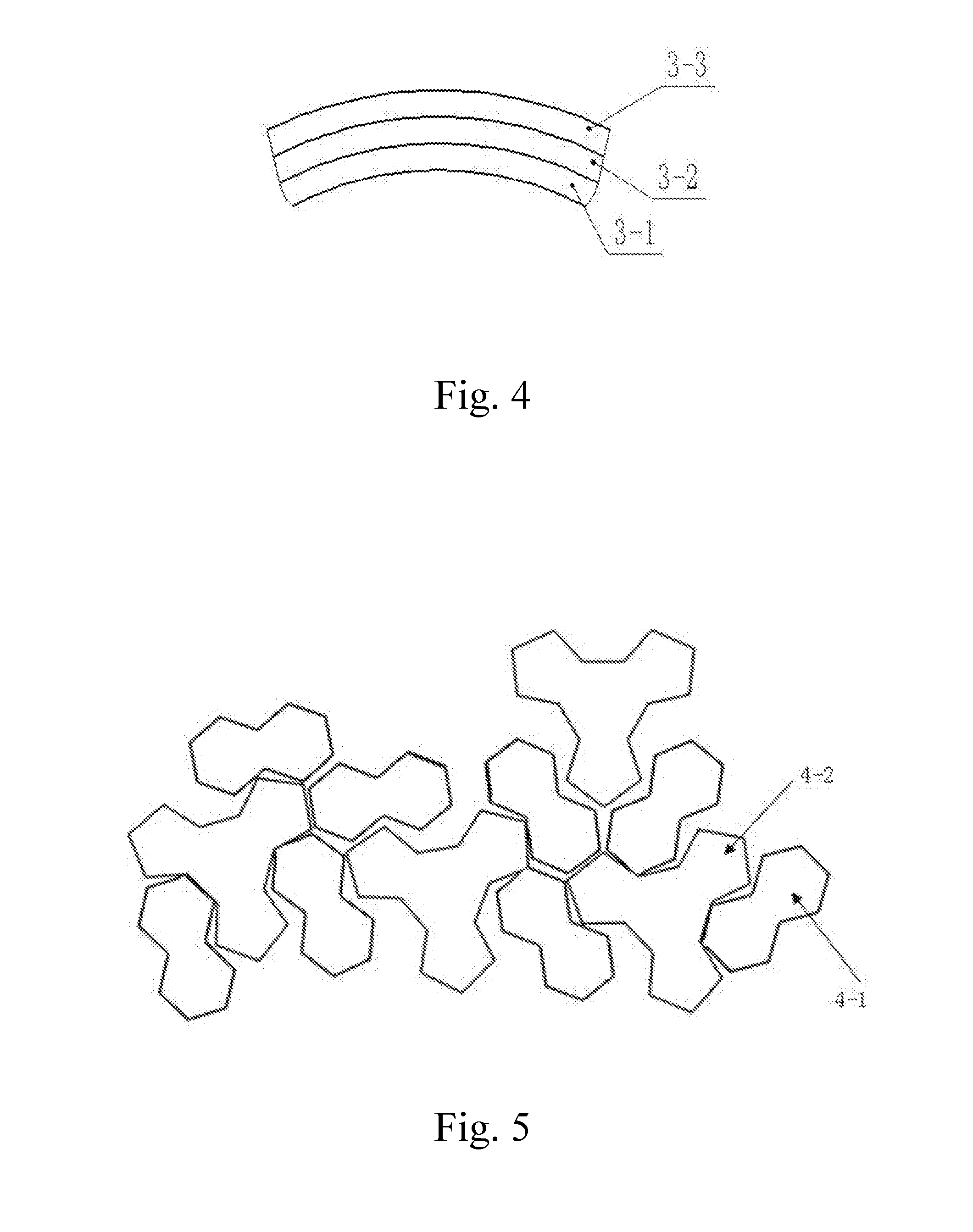

[0049]As shown in FIG. 2, if a balance and a flight stability of the ball are ensured, when a player hits the ball, an actual flight trajectory of the ball deviates from an ideal trajectory thereof in small, so that a hit rate of the ball is increased. Accordingly, a balance plate 7 is located on the inner tube 5 provided by the present invention, and is coaxially aligned with a gas nozzle 6 and symmetrical to a spherical center, such that a whole center of gravity of the ball lies in the spherical center.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com