Intercrystalline corrosion-resistant aluminium alloy strip, and method for the production thereof

a technology of intercrystalline corrosion and aluminium alloy, which is applied in the field of aluminum alloy strips, can solve the problems that normal aluminium alloy strips can become susceptible to intercrystalline corrosion, and aluminium strips are therefore unsuitable for use in heat-stressed areas, and achieve the effects of reducing the risk of intercrystalline corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

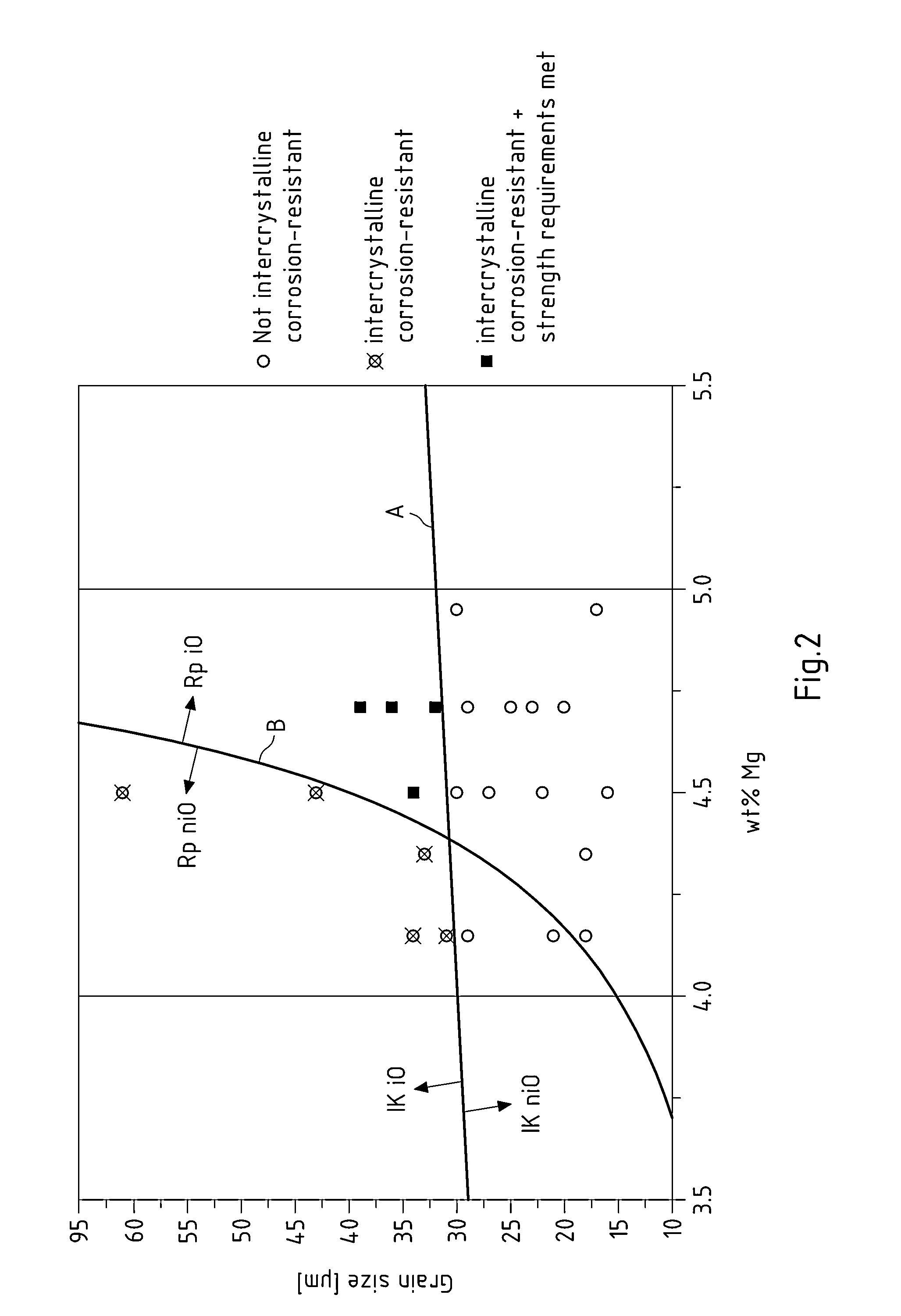

[0053]Extensive trials were carried out to investigate if there is a link between the grain size of an aluminium alloy strip in an AA 5xxx-type aluminium alloy and the Mg content in terms of the resistance to intercrystalline corrosion. To this end, various aluminium alloys were used and different process parameters applied. Table 1 shows the various alloy compositions, on the basis of which the relationship between grain size, resistance to intercrystalline corrosion and yield point was investigated. Apart from the contents of the alloying elements Si, Fe, Cu, Mn, Mg, Cr, Zn and Ti in wt. %, the aluminium alloys shown Table 1 comprise as remainder aluminium and inevitable impurities, each of which amounts to a maximum of 0.05 wt. % and the total amount of which amounts to no a maximum of 0.15 wt. %.

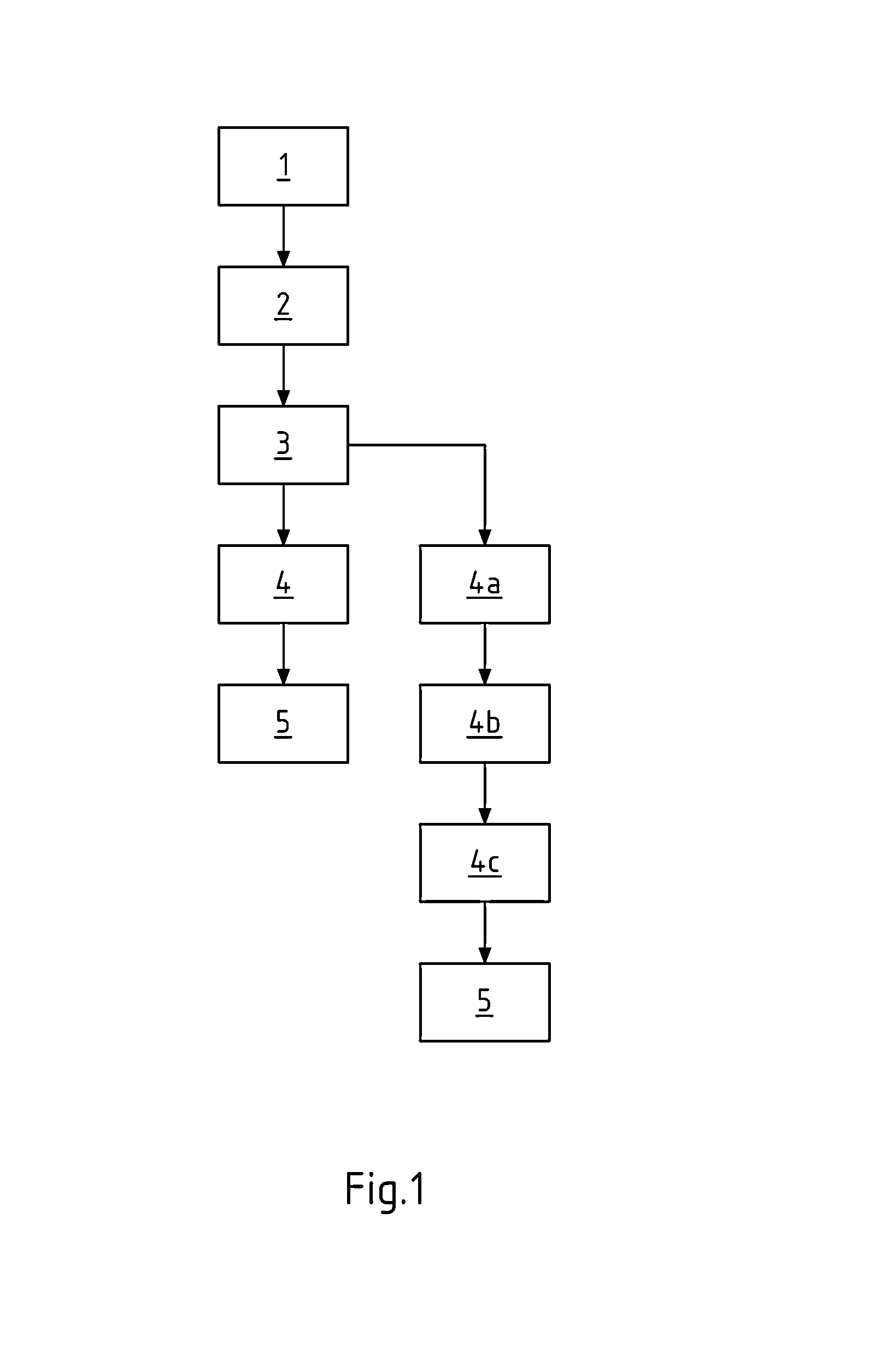

[0054]Since, in particular, the final annealing and the final degree of rolling have an influence on the grain size, these were varied and / or measured during the respective trials. The g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength Rm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com