Method for packaging medical supplies

a medical supply and packaging technology, applied in the field of packaging medical supplies, can solve the problems of long storage time and achieve the effect of preventing bleaching of medical supplies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

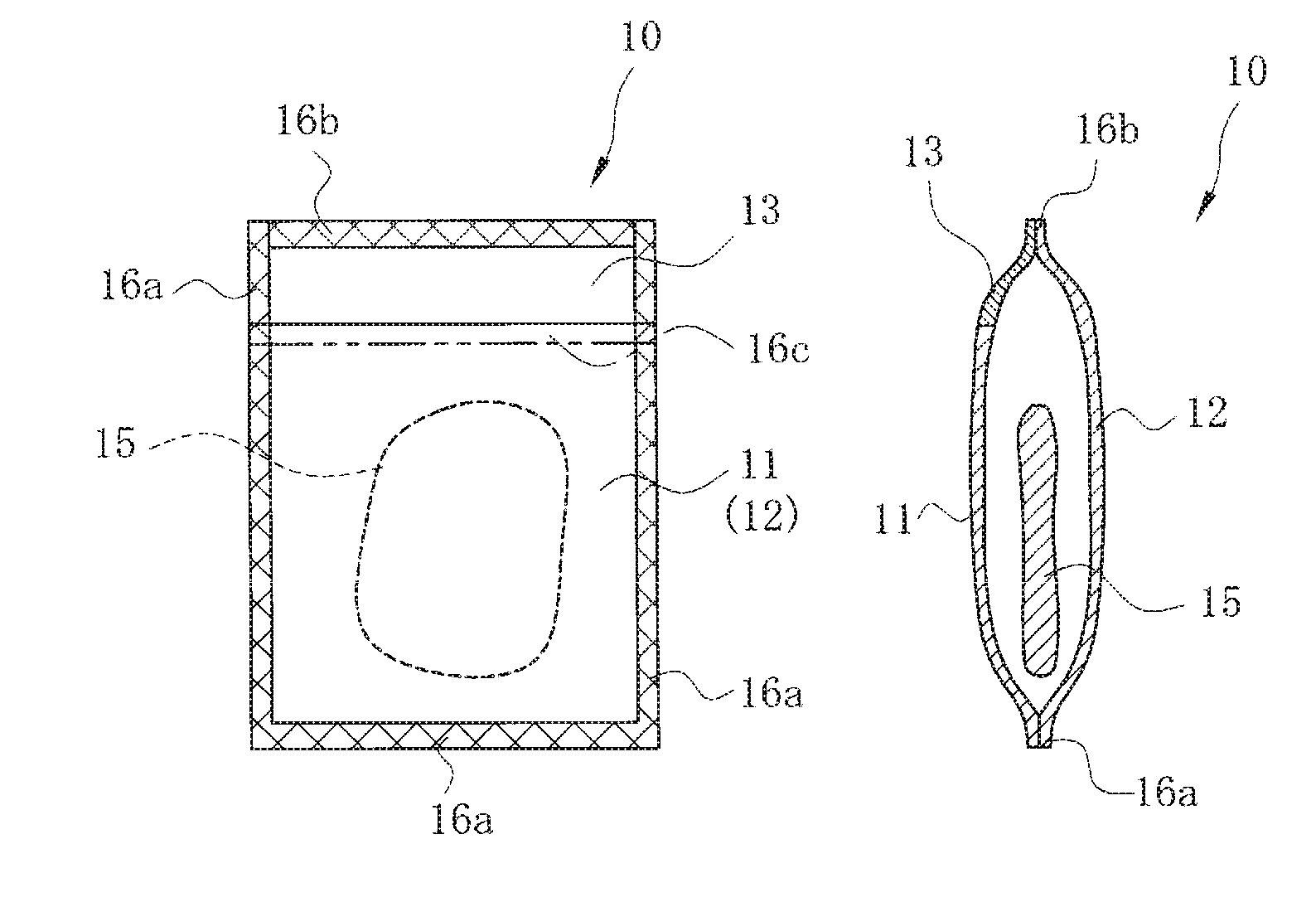

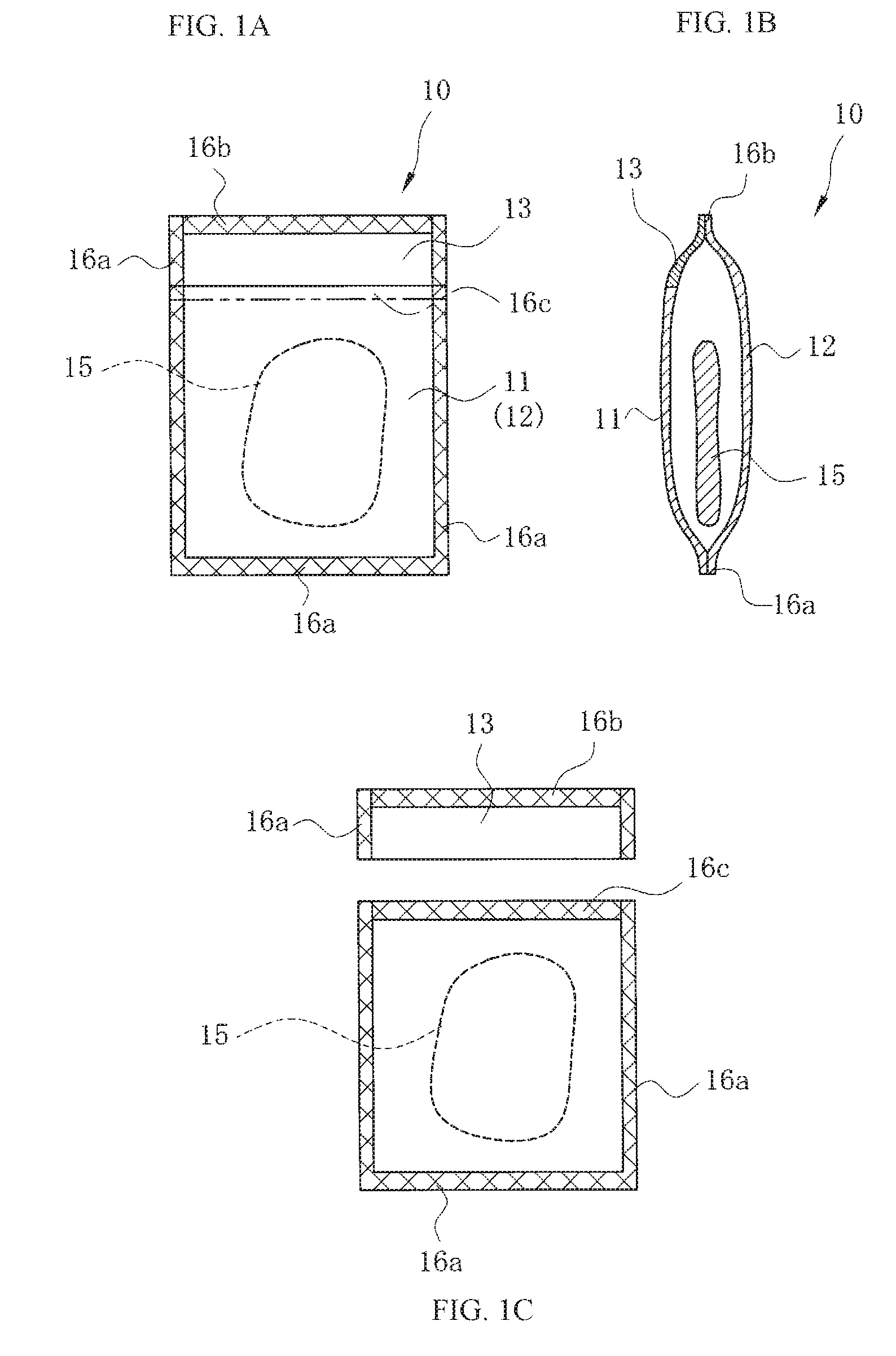

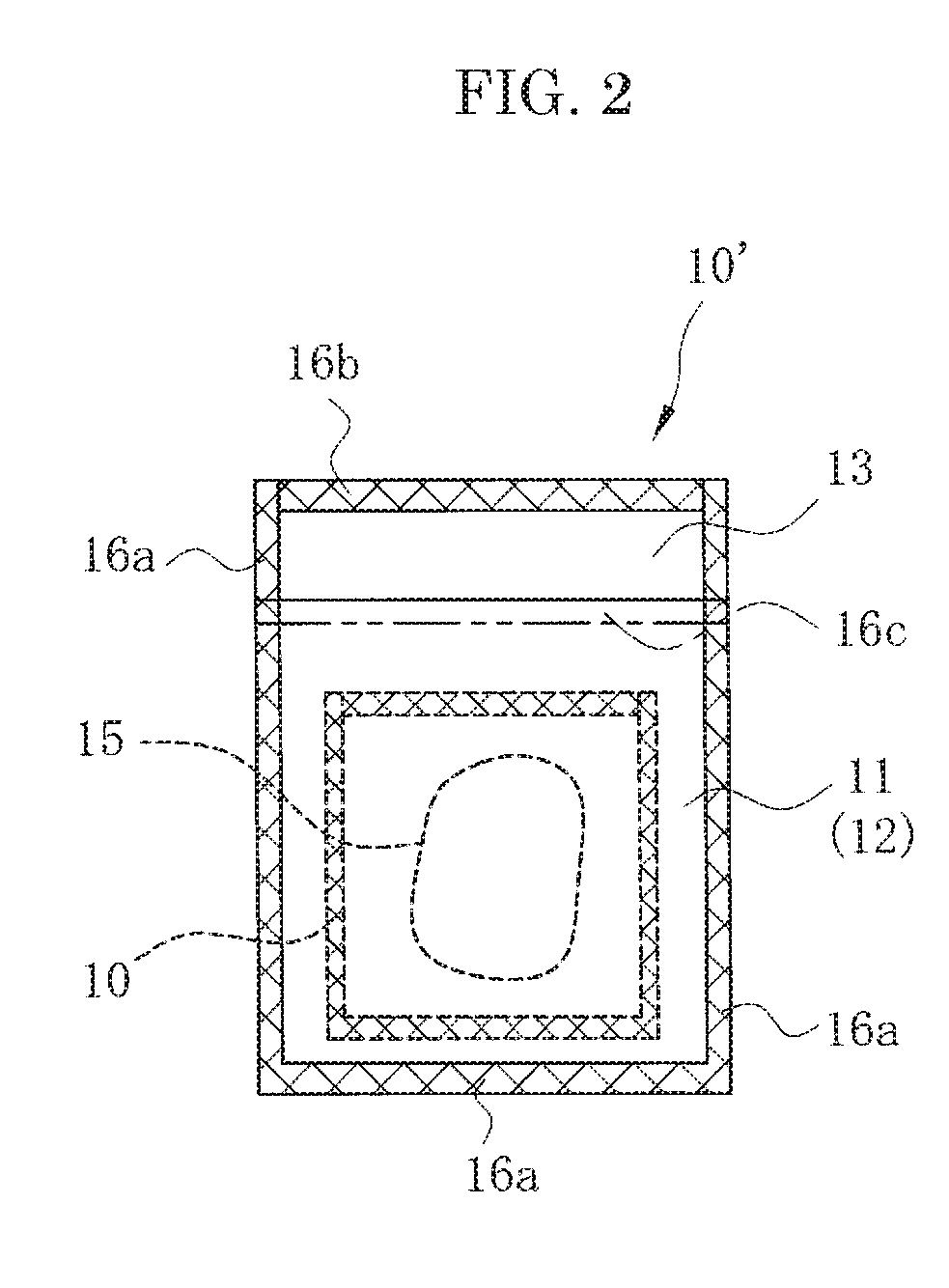

Image

Examples

working example 1

[0040]Table 1 shows results from an experiment using four types of packaging bags A, B, C, and D. In Table 1, thickness (μm) is thicknesses of the films 11 and 12 constituting the packaging bag 10 for medical supplies, where 50+80 denotes that thickness of the film 11 is 50 micrometers and that of the other film 12 is 80 micrometers. Both of these films have used a film on which silica is deposited on each side.

TABLE 1Oxygen7 days later14 days laterThicknesstransmissionChangeChangeSample(μm)(cm3 / m2day)in colorStrengthin colorStrengthA80 + 800.06⊚44.7⊚45.3B50 + 800.09⊚44.2Δ40.8C80 + 800.13Δ39.5X19.7D50 + 800.20X33.8X16.1Control——⊚44.1⊚44.1⊚ No decolorizationΔ Slight decolorizationX Decolorization

[0041]Oxygen transmittance (unit is cm3 / m2·day·atm) is transmission between inside and outside the packaging bag 10. Oxygen transmittance of both the film 11 and the film 12 is in a combined state.

[0042]Change in color means that whether or not decolorization has occurred has been visually de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com