Electric motor and electric pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

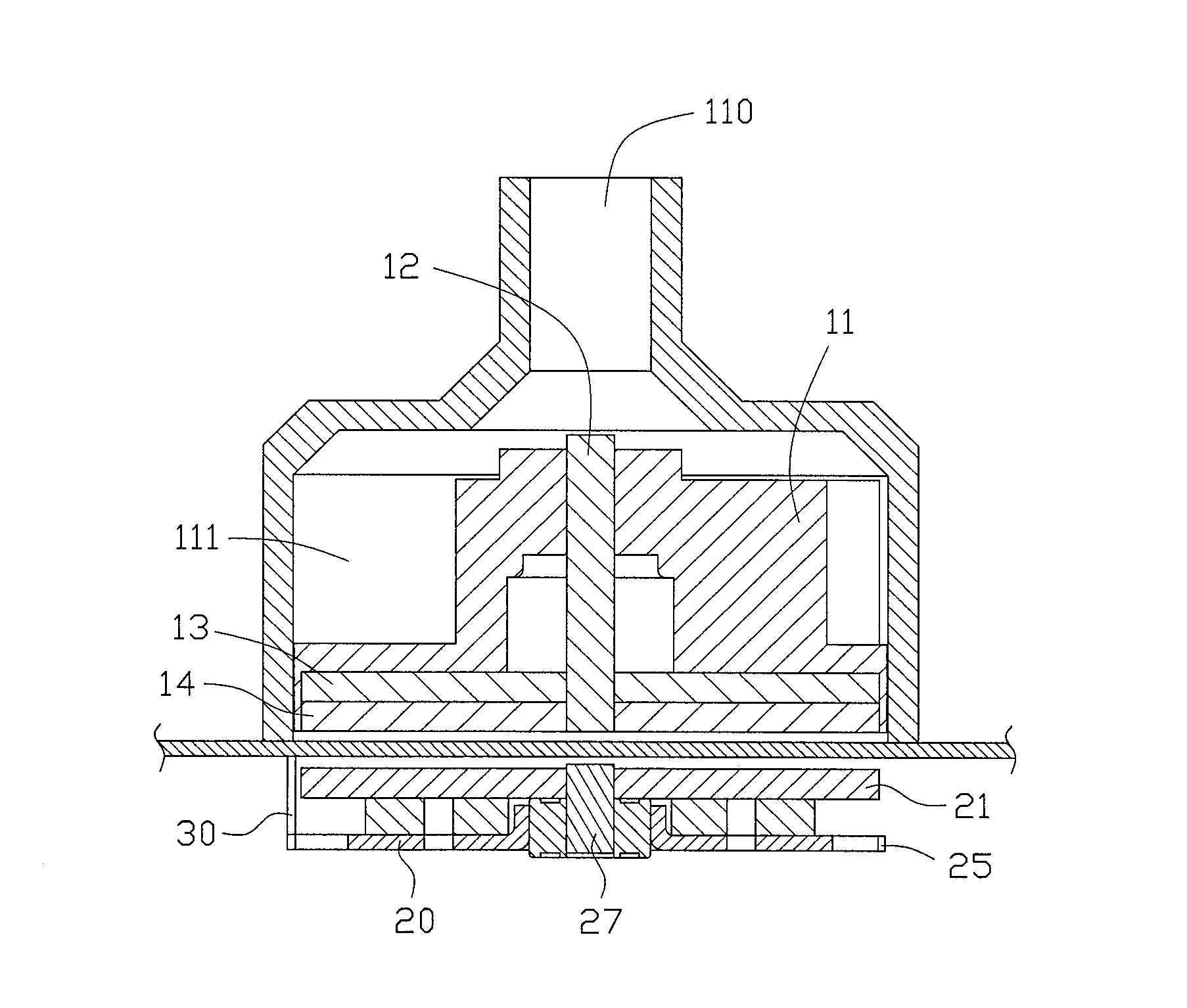

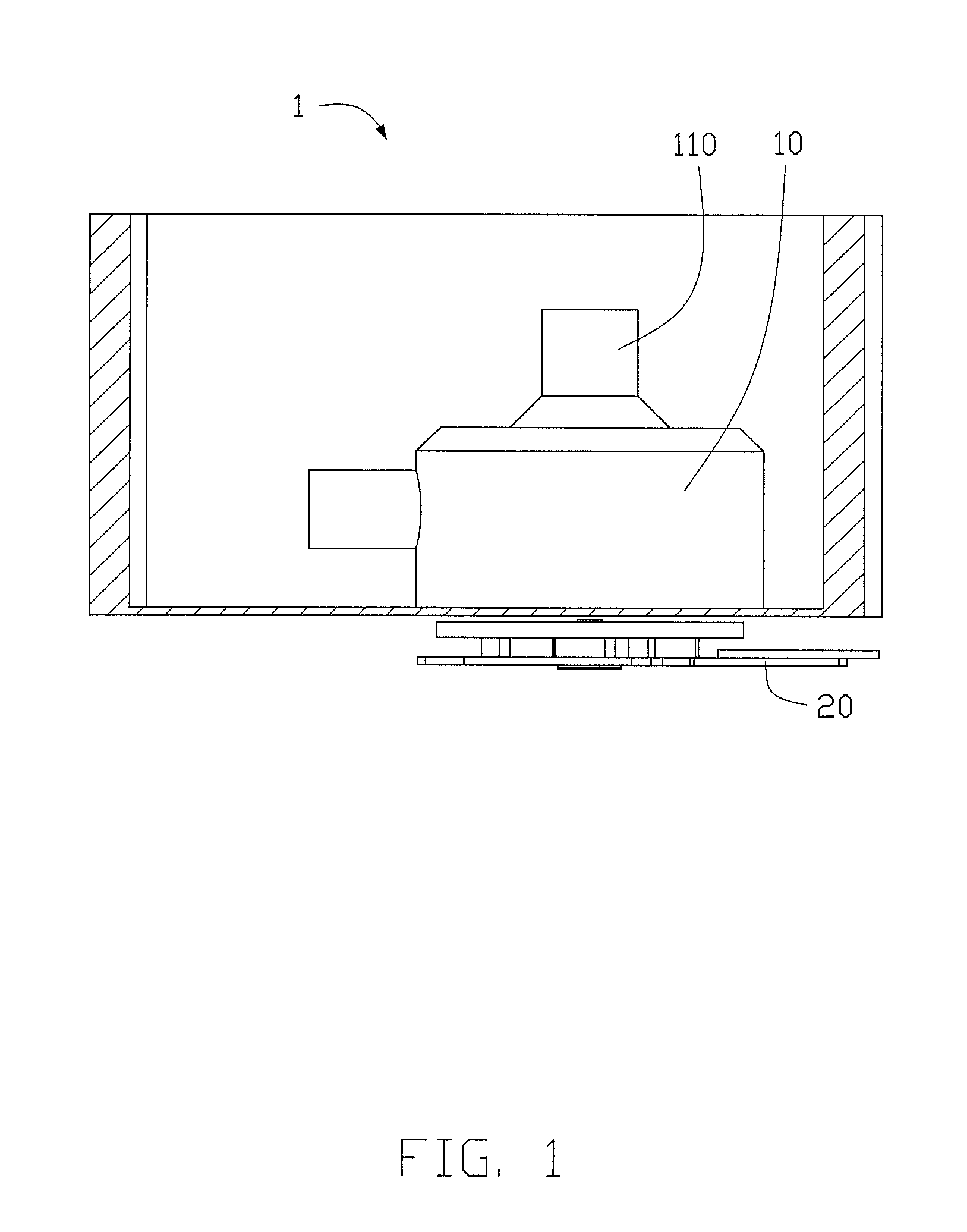

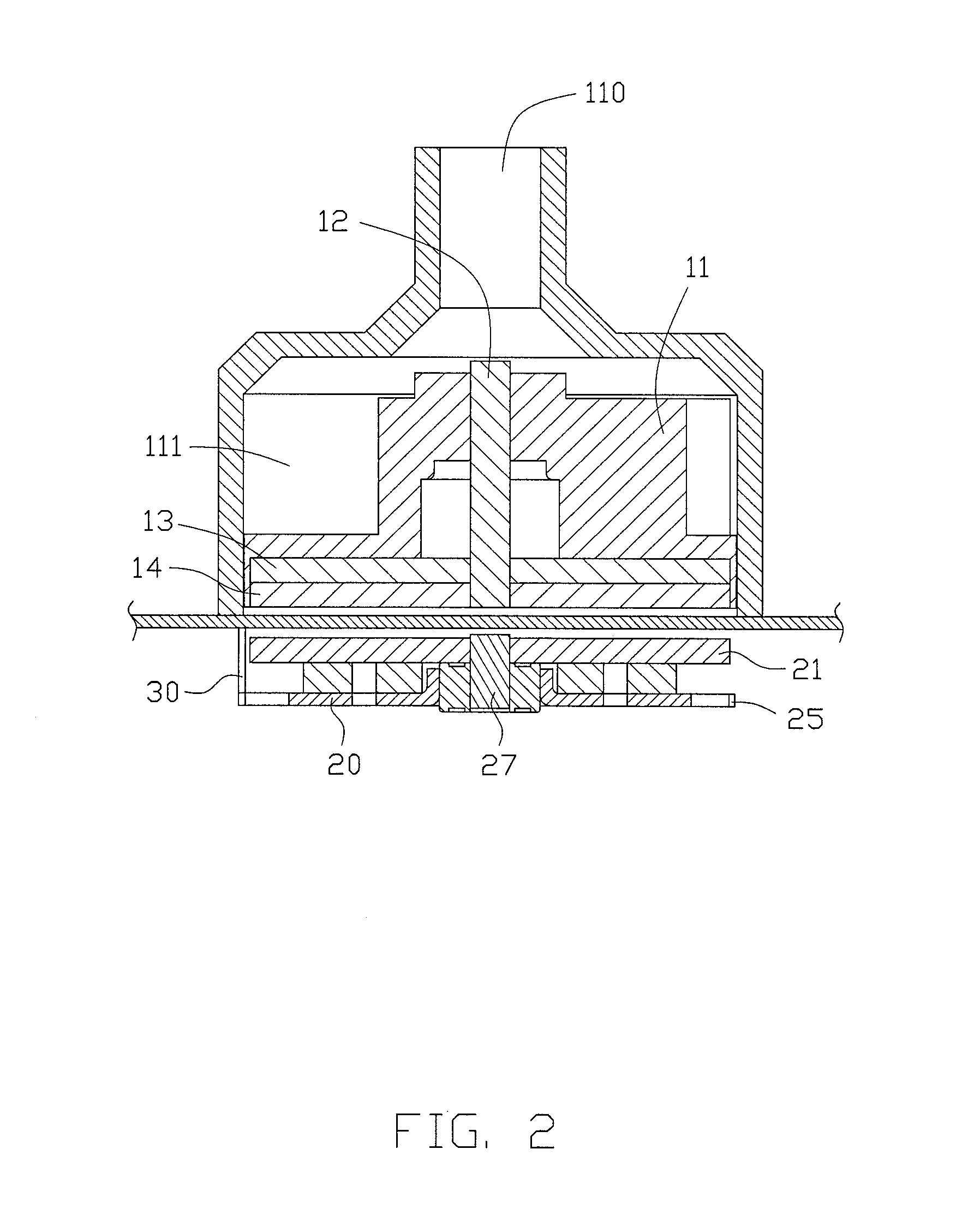

[0027]FIG. 1 is a schematic view of an electric pump 1 in accordance with a preferred embodiment of the invention. FIG. 2 is a sectional view of the pump. The pump 1 includes a pump body 10, a pump magnet 14 disposed in the pump body 10, an impeller 11 disposed in the pump body 10 and fixed with the pump magnet 14, and a disc type electric motor 20 for rotating the pump magnet 14 and the impeller 11 within the pump body 10. In this embodiment, the disc type electric motor 20 is a brushless electric motor. In other embodiments, the disc type electric motor 20 may be a brush type electric motor.

[0028]In this embodiment, the pump magnet 14 and the impeller 11 are rotatably fixed to an inner surface of a bottom of the pump body 10 via a spindle 12 and a bearing (not shown), such that the impeller and pump magnet are able to rotate about the axis of the spindle within the pump body 10. The spindle 12 may or may not be rotatable. The pump 10 includes a water inlet 110 and a water outlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com