Aluminum alloy plastic worked article, method for manufacturing the same, and automobile component

a technology of aluminum alloy and worked articles, which is applied in the field of aluminum alloy plastic worked articles, can solve the problems of insufficient use of si-based aluminum alloy raw materials in a severe corrosive environment, inability to suppress the generated corrosion weight loss, and may generate stress corrosion cracks in some cases, so as to achieve excellent corrosion resistance, preferable aluminum texture state, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0103]Next, Examples of the present invention will be described.

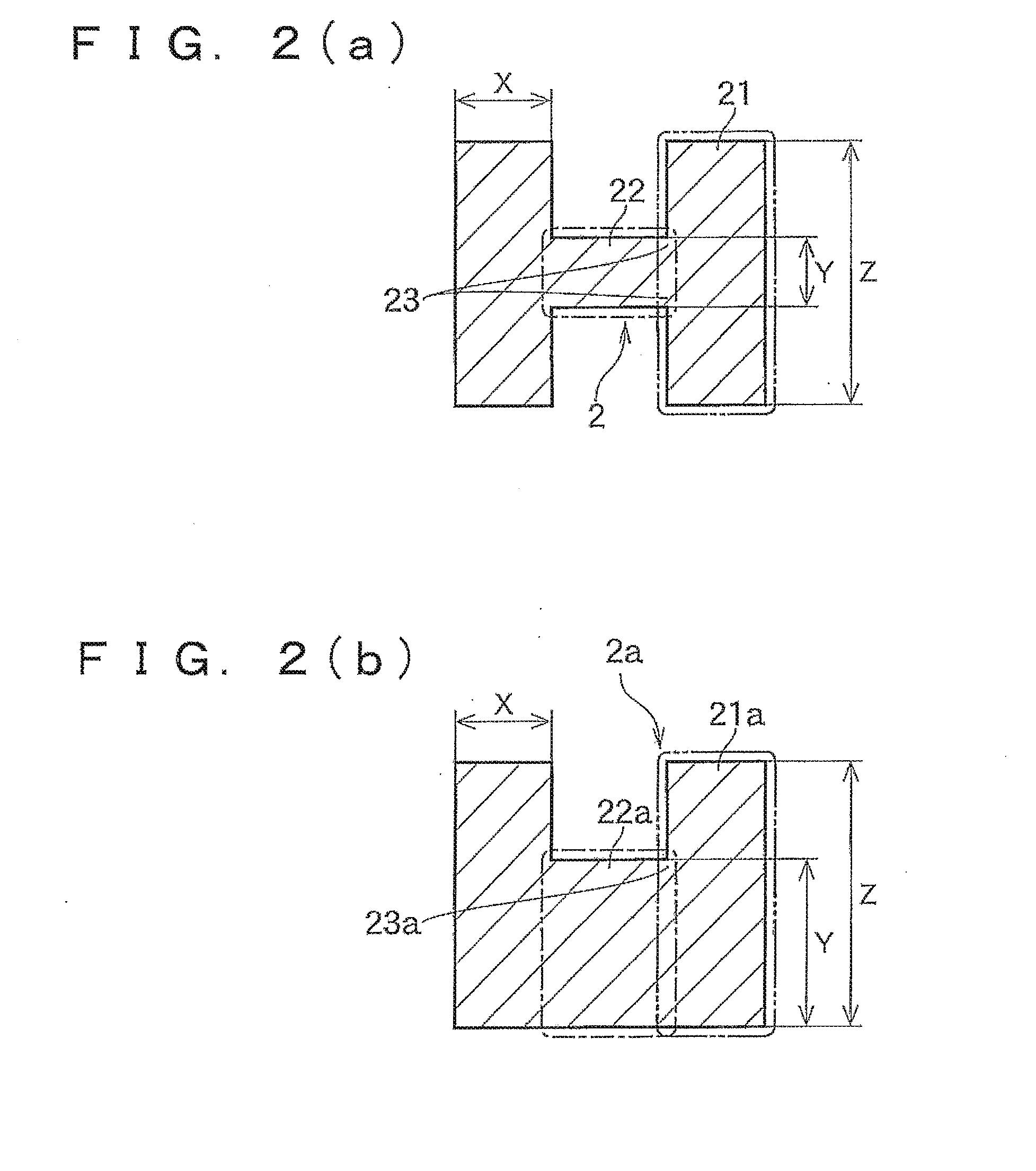

[0104]In the following [Table 1], there are shown the composition; the cross-sectional shape of the plastic worked portion; and the width direction length x (cm) of the rib portion, the height direction length y (cm) of the thinned portion, and the height direction length z (cm) of the rib portion, which define the shape of the rib portions and the thinned portion, of each of an aluminum alloy plastic worked article (Comparative Example 1) formed from an A6000 series aluminum alloy, related aluminum alloy plastic worked articles (Comparative Examples 2 and 3) possessed by the applicant, and aluminum alloy plastic worked articles (Examples 1, 2, and 3) according to the present invention.

TABLE 1CuMgSiMnFeComparative Example 10.331.050.700.120.25Comparative Example 20.401.000.820.200.25Comparative Example 30.330.981.050.500.25Example 10.330.981.050.500.25Example 20.420.861.110.500.26Example 30.410.871.090.410.25CrZnZrTiBCo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com