Ultra low NOX insulating burner without collar

a burner and low nox technology, applied in the field of burners, can solve problems such as damage and/or deformation of partition plates, and achieve the effect of limited heat transfer between the flange and the adjacent componen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

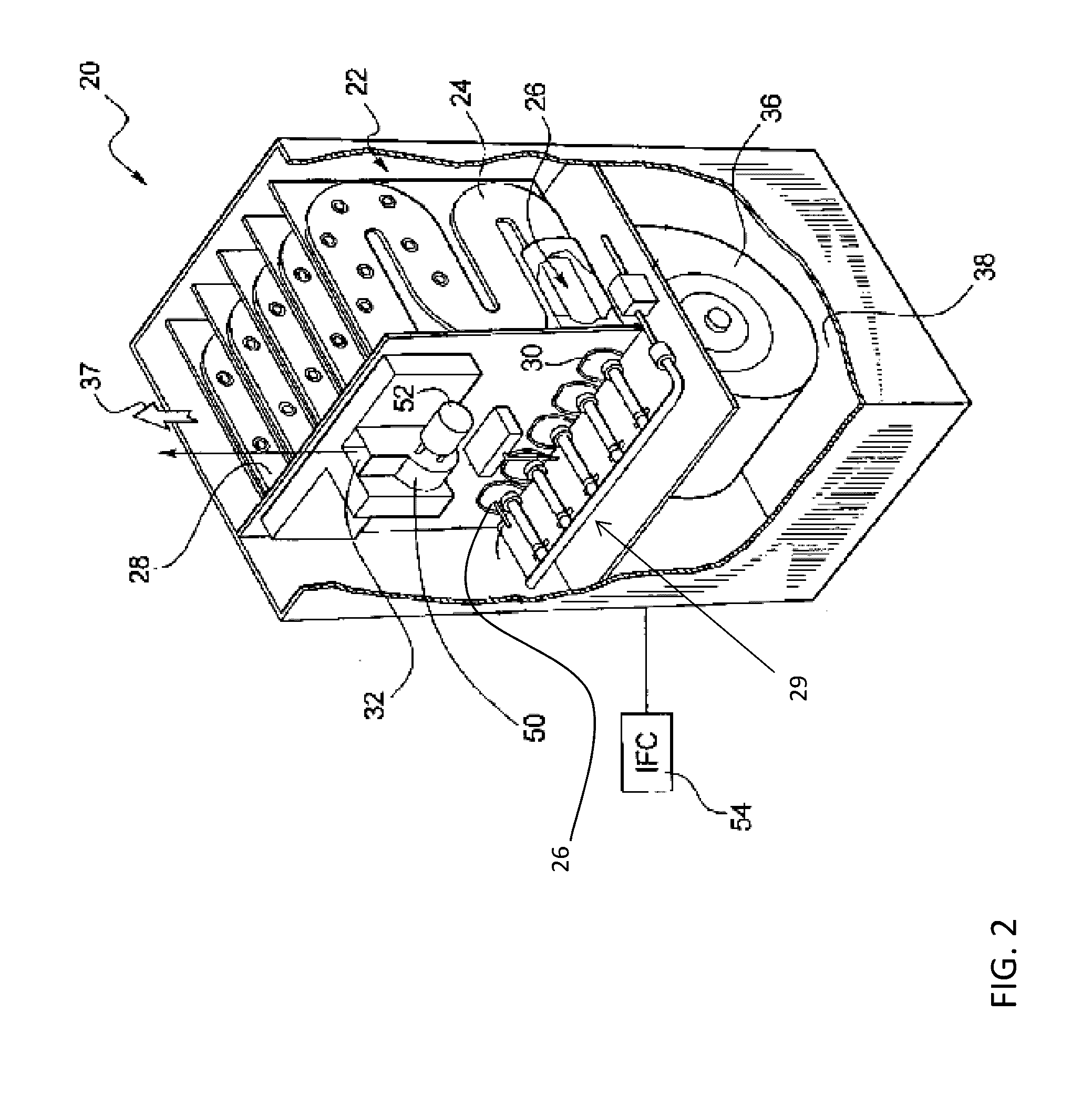

[0033]Referring now to FIG. 2, an improved furnace 20 is illustrated. The furnace 20 may include a heat exchanger 22 having a plurality of individual heat exchanger coils 24. The heat exchanger coils 24, which may be metallic conduits, may be provided in a serpentine fashion to provide a large surface area in a small overall volume of space. Each heat exchanger coil 24 includes an inlet 26 and outlet 28. A burner assembly 29 includes a burner 30 operatively associated with each inlet 26, and a vent 32 operatively associated with each outlet 28. The burner assembly 29 introduces a flame and combustion gases (not shown) into the heat exchanger coil 24, while vent 32 releases the combustion gases to atmosphere (through a flue or the like) after the heat of the flame and combustion gases is extracted by the heat exchanger 22.

[0034]In order to extract the heat, a blower motor 36 may be provided to create a significant air flow across the heat exchanger coils 24. As the air circulates acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com