Method for the production of liquefied natural gas and nitrogen

a technology of liquefied natural gas and nitrogen, which is applied in the direction of liquefaction, solidification, cold treatment separation, etc., can solve the problems of uneconomical options and high product cost, and achieve the effect of less cost, more efficient and flexible methods of producing lng

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]While the invention will be described in connection with several embodiments, it will be understood that it is not intended to limit the invention to those embodiments. On the contrary, it is intended to cover all the alternatives, modifications and equivalence as may be included within the spirit and scope of the invention defined by the appended claims.

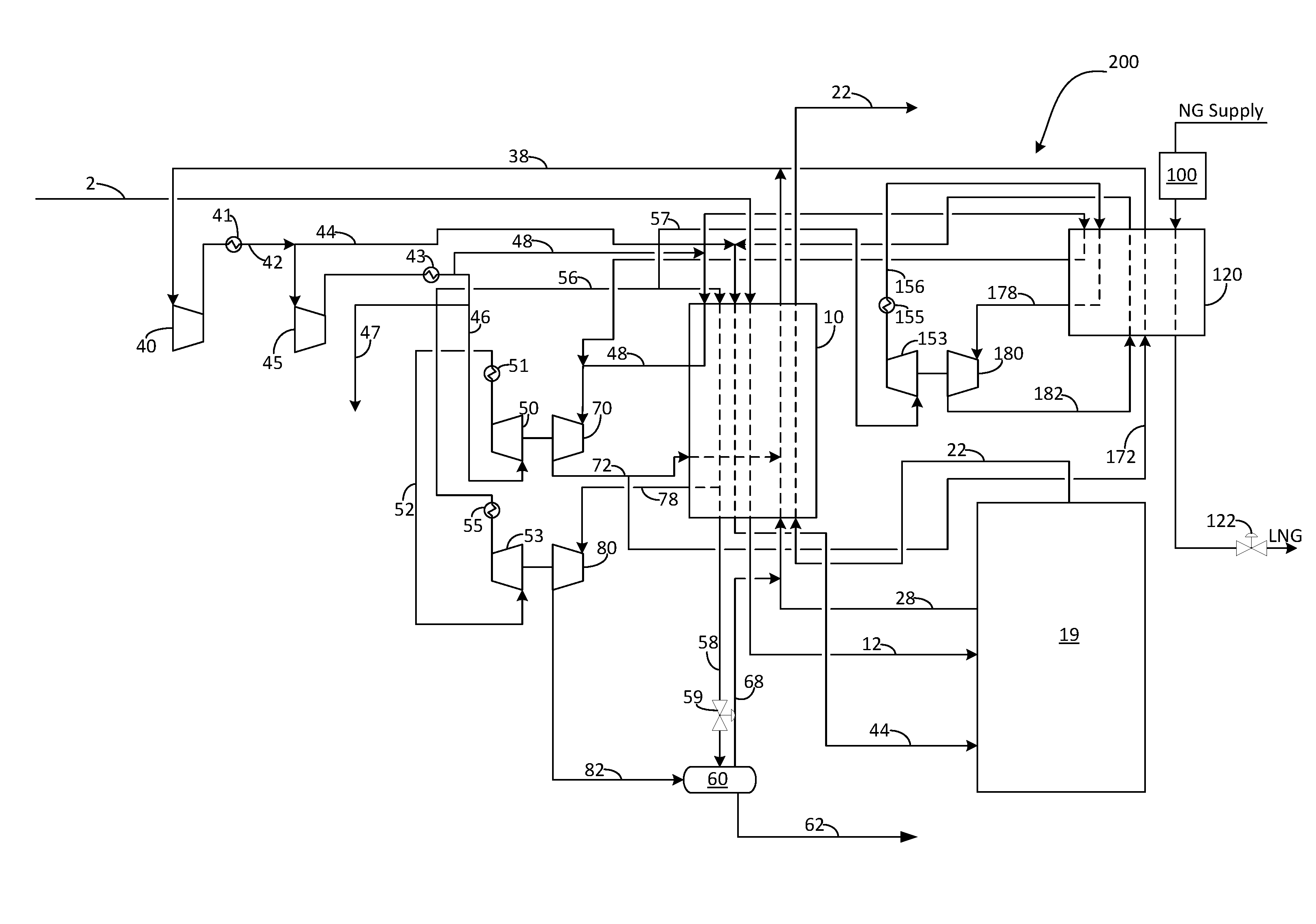

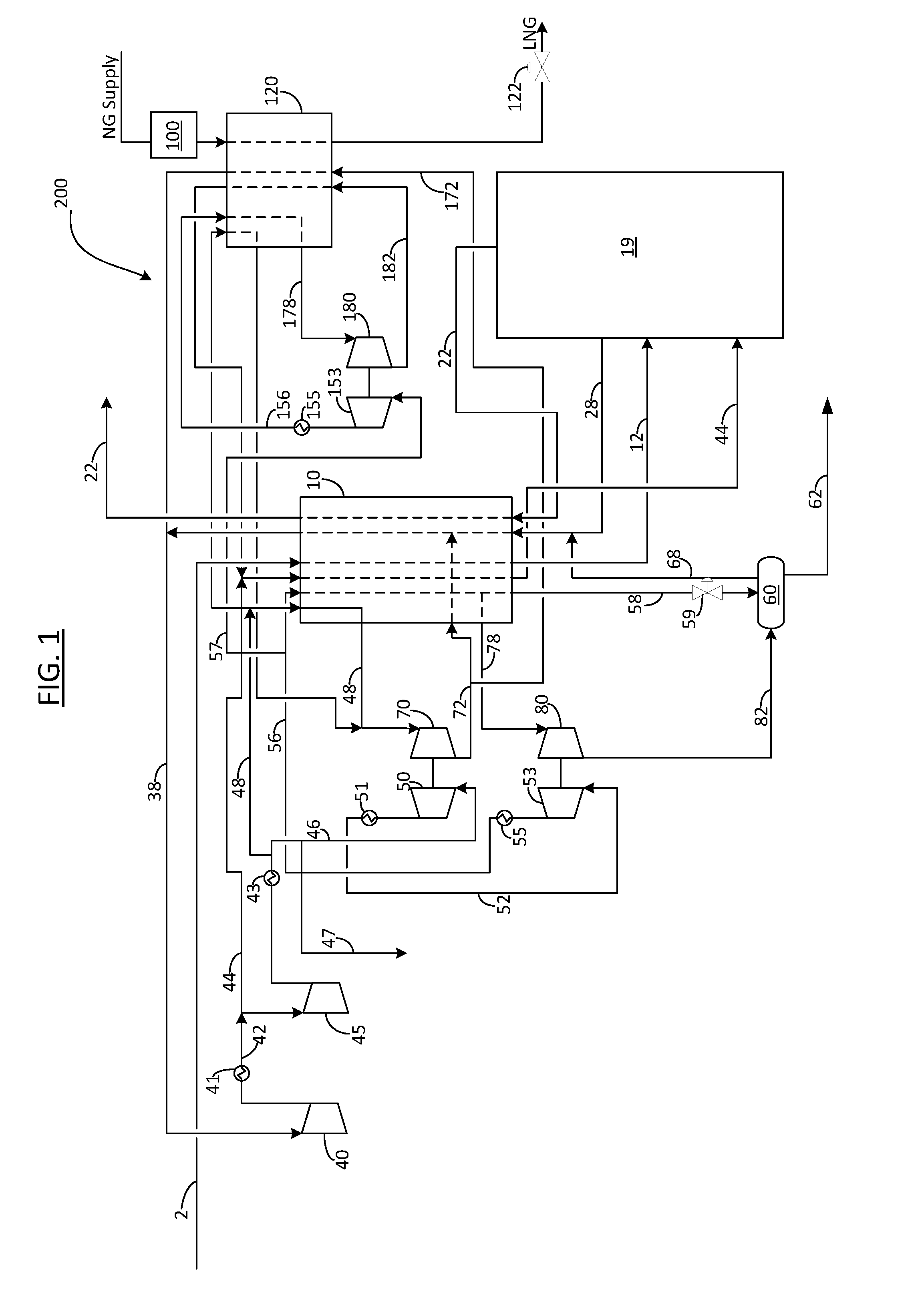

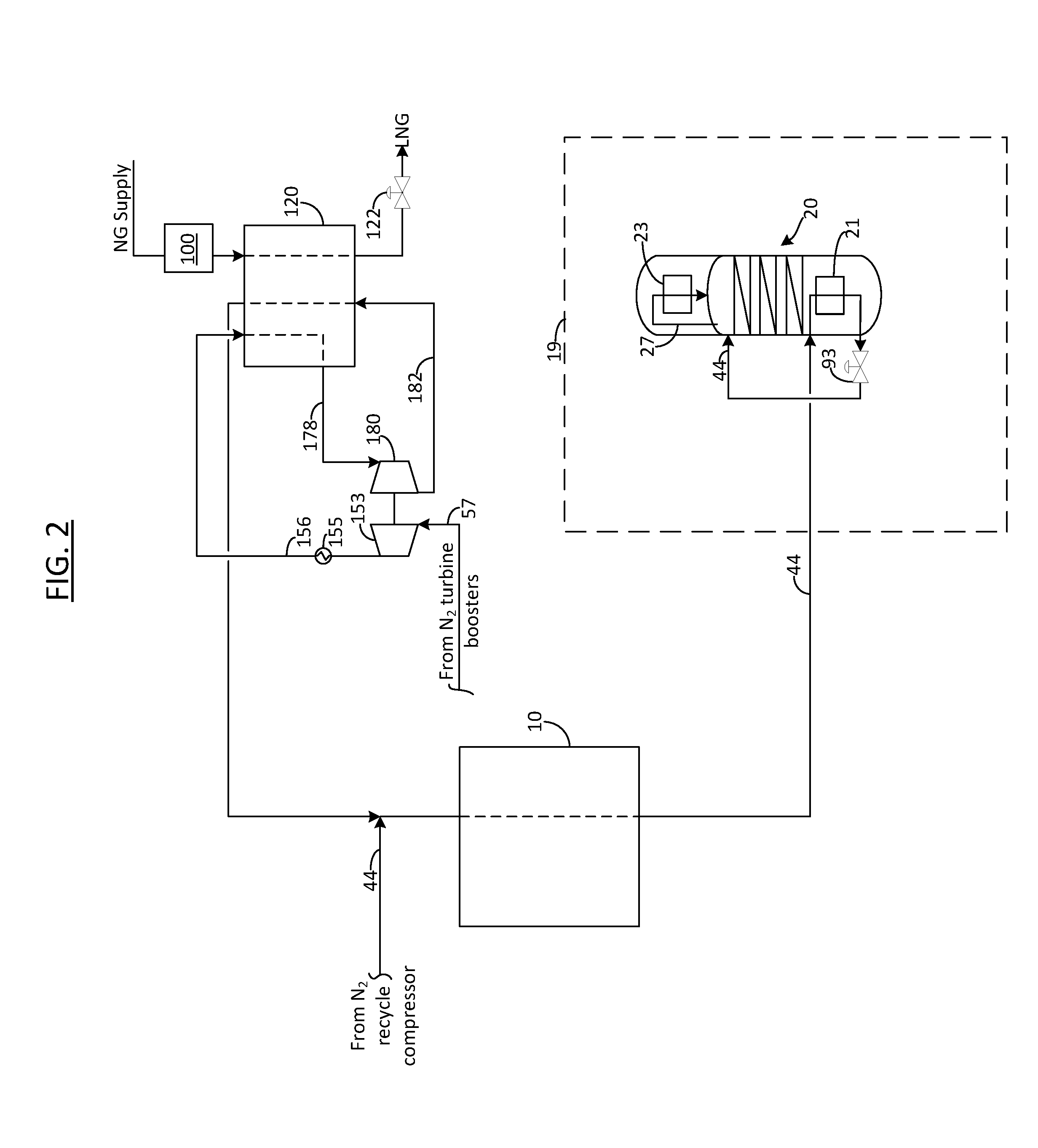

[0032]In one embodiment, the apparatus can include a Main Air Compressor (MAC), an air purification system, heat exchange means, a distillation column, and a nitrogen refrigeration cycle having a nitrogen recycle compressor and warm and cold turbine boosters. In one embodiment, the nitrogen refrigeration cycle provides compression energy for pressurized gaseous nitrogen product as well as refrigeration for both cooling down the incoming air and liquefy nitrogen, as well as providing refrigeration to liquefy the natural gas to LNG. In one embodiment, the warm turbine booster flow can be split to provide refrigeration to both th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com