PCM container approximating a container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

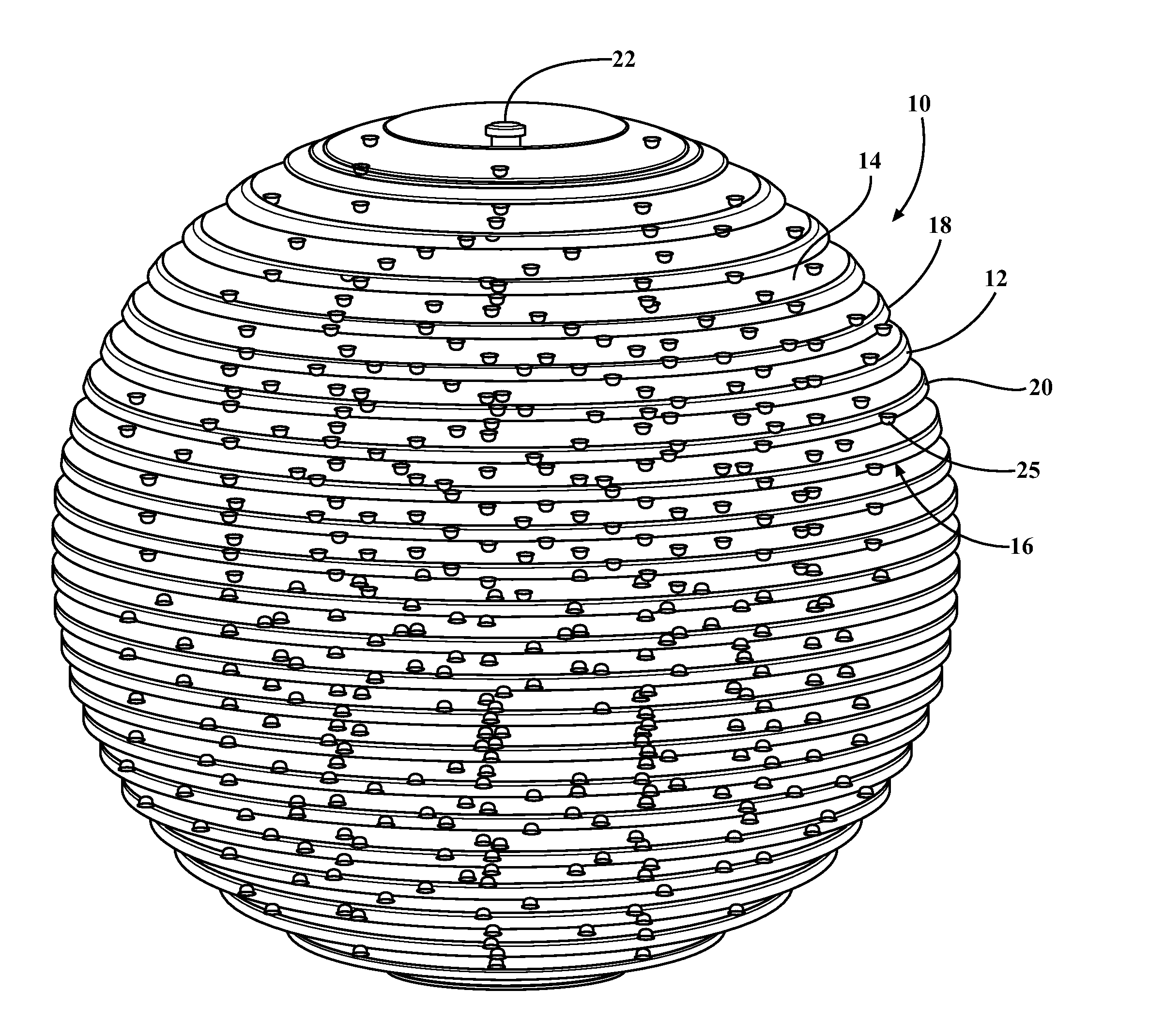

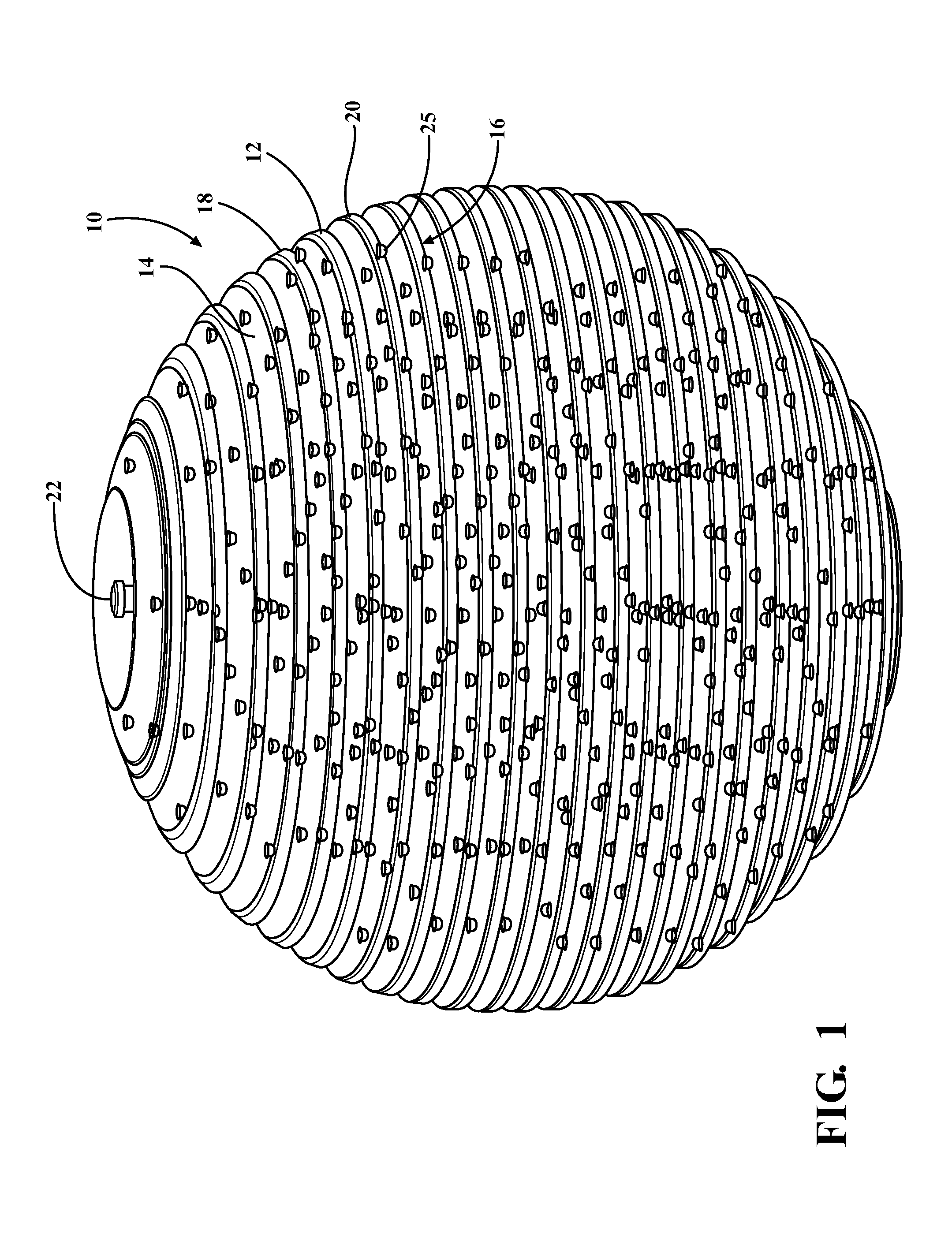

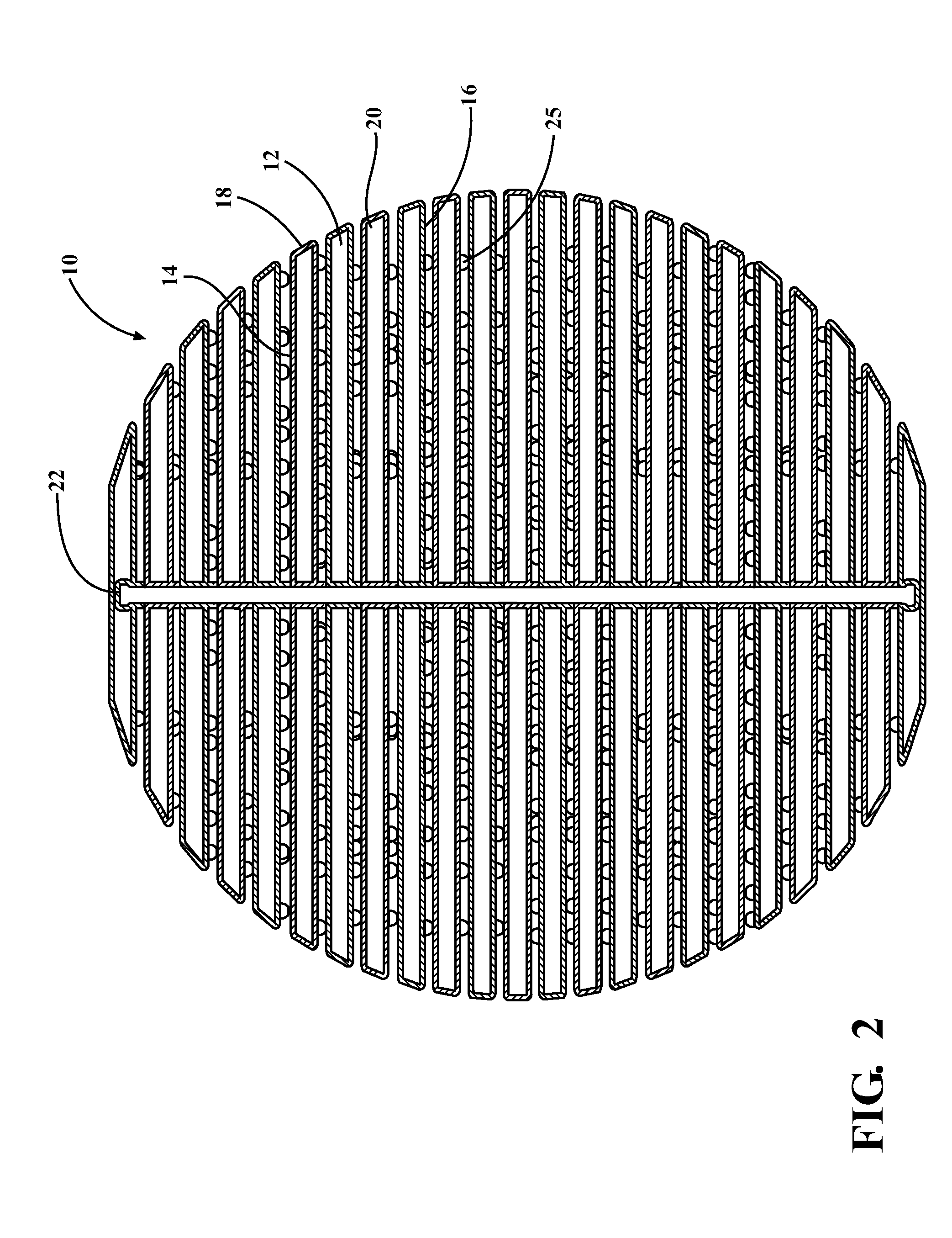

[0026]The present invention provides a larger thermal energy material (i.e. phase change material, hereinafter referred to as ‘PCM’) container assembly that approximates a sphere's external perimeter in three dimensions.

[0027]It should be noted that this description continuously refers to a general thermal energy material as a PCM. In this specification, the terms PCM and thermal energy material may be used interchangeably. Thermal energy material is defined as any material that can store or move energy, such as a PCM. The thermal energy material may also be referred to as a heat transfer fluid. Referring to FIG. 1, an exemplary container assembly in accordance with one embodiment of the present invention is shown at 10. FIG. 2 shows a cross sectional view. The container assembly 10 is composed of a plurality of generally flat containers that each approximate a segment of a sphere, geometrically described as a spherical segment. A spherical segment is the solid defined by cutting a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com