Integrated access floor system

a technology of access flooring and composite trusses, which is applied in the direction of space heating and ventilation, lighting and heating apparatus, heating types, etc., can solve the problems of system not integrating access flooring into the top slab of composite trusses, and the limitations of the diaphragm construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

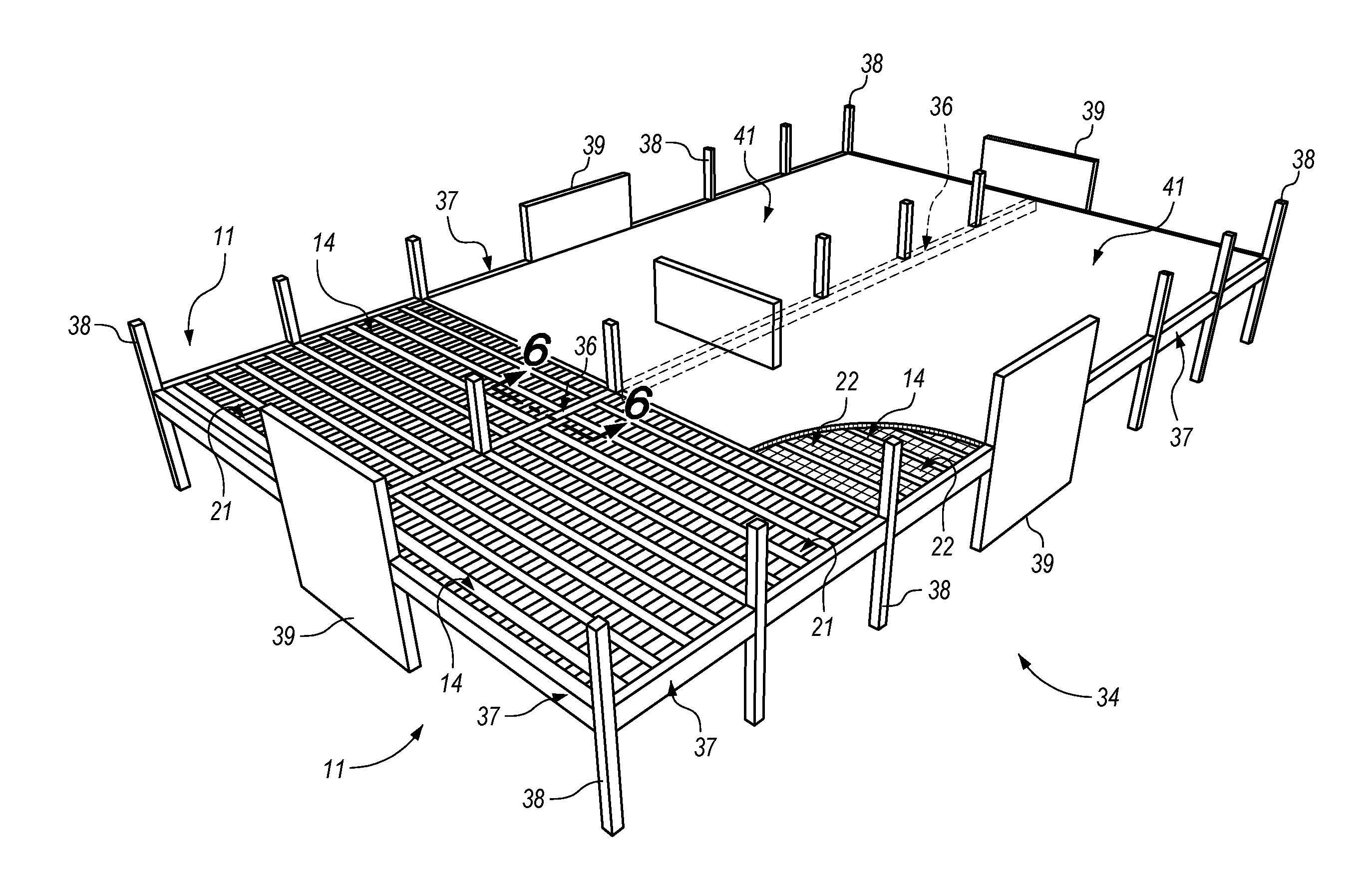

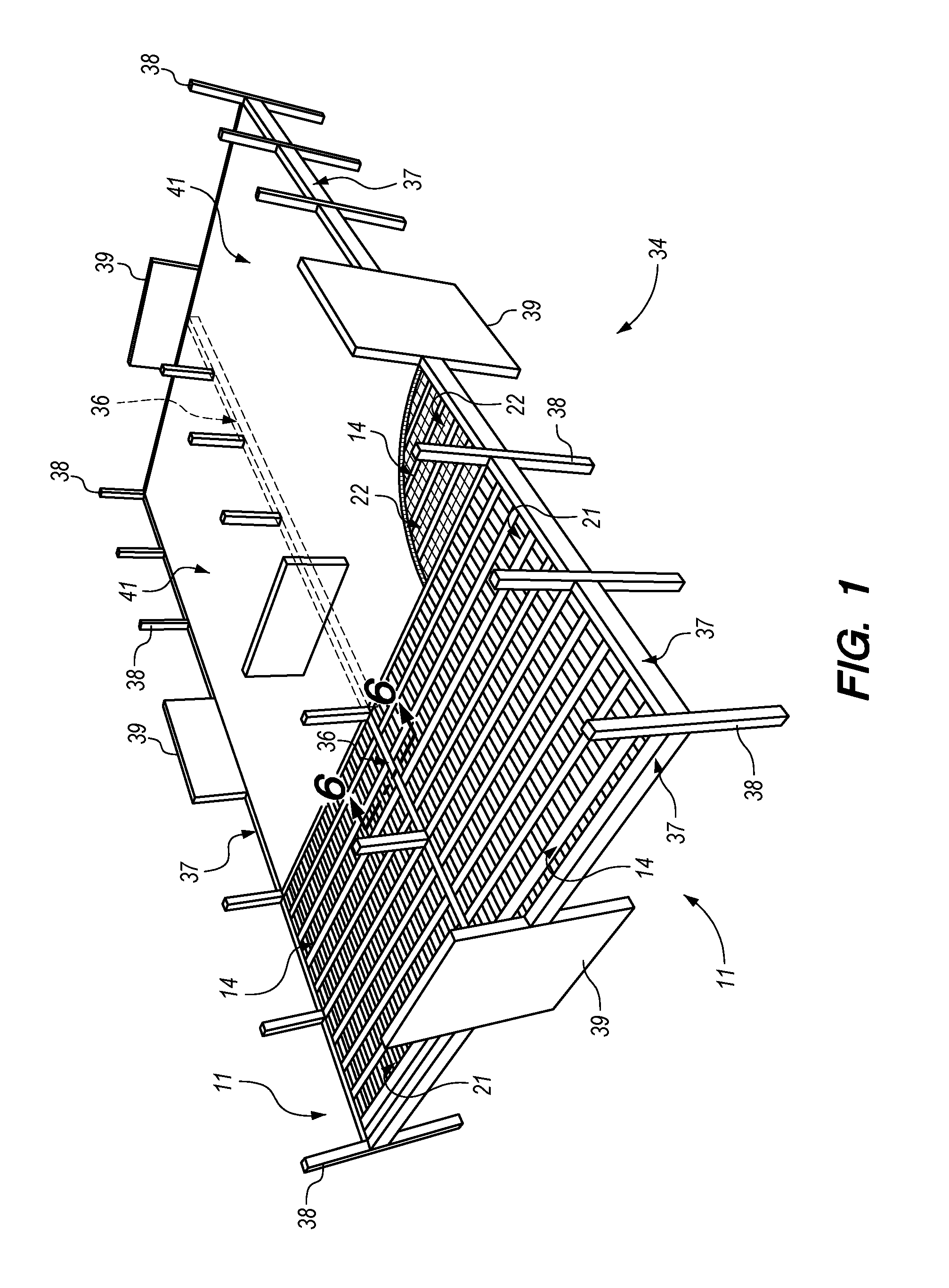

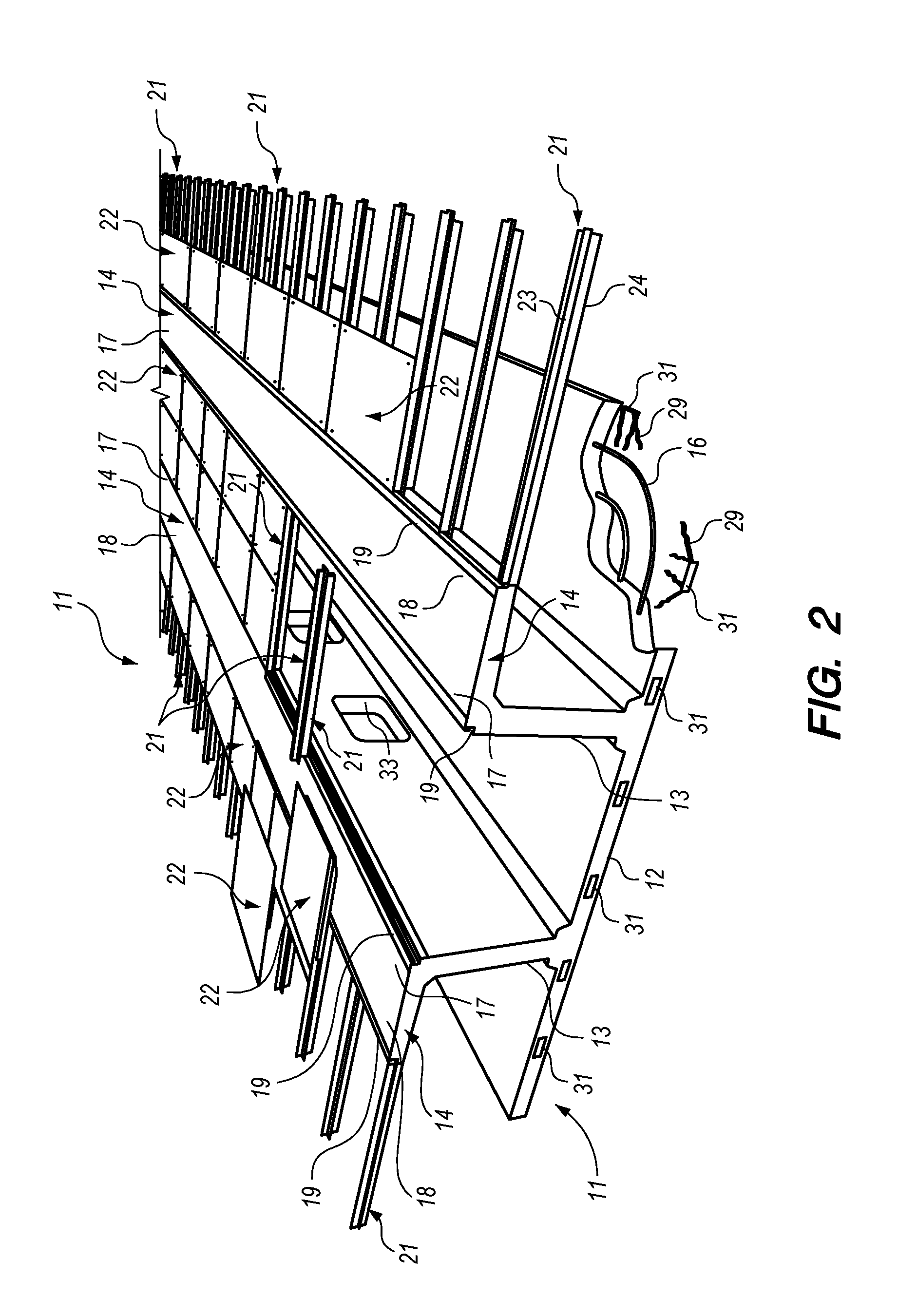

[0046]Turning now to the drawings, and in particular FIGS. 1 and 2, an integrated access deck panel 11 is shown. Preferably deck panels 11 are manufactured at a facility off-site from a main building site. At the manufacturing facility, individual panels 11 are pre-cast from concrete into an integrated structure, including whatever customized structural or architectural features are called for. After the panels 11 have cured, they are transported to the building site where they can be assembled and joined with other building structures and assemblies. This manner of construction, involving prefabrication of major structural components off-site, has been proven to save labor costs and to accelerate construction speed, compared to conventional methods of construction.

[0047]The access deck panel 11 includes a bottom flange 12, one or more structural webs 13, and an optional top flange 14. The bottom flange 12 acts as a ceiling soffit for the floor below, and its underside may include d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com