Repair kit for preparing polymeric compositions for repairing surfaces and methods of use thereof

a polymeric composition and kit technology, applied in the direction of containers, transportation and packaging, internal fittings, etc., can solve the problems of user exposure to undesirable chemicals, batch mixing uses bulky and expensive equipment and instruments to mix components, and it is difficult to transport bulky equipment to more remote locations for surface repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

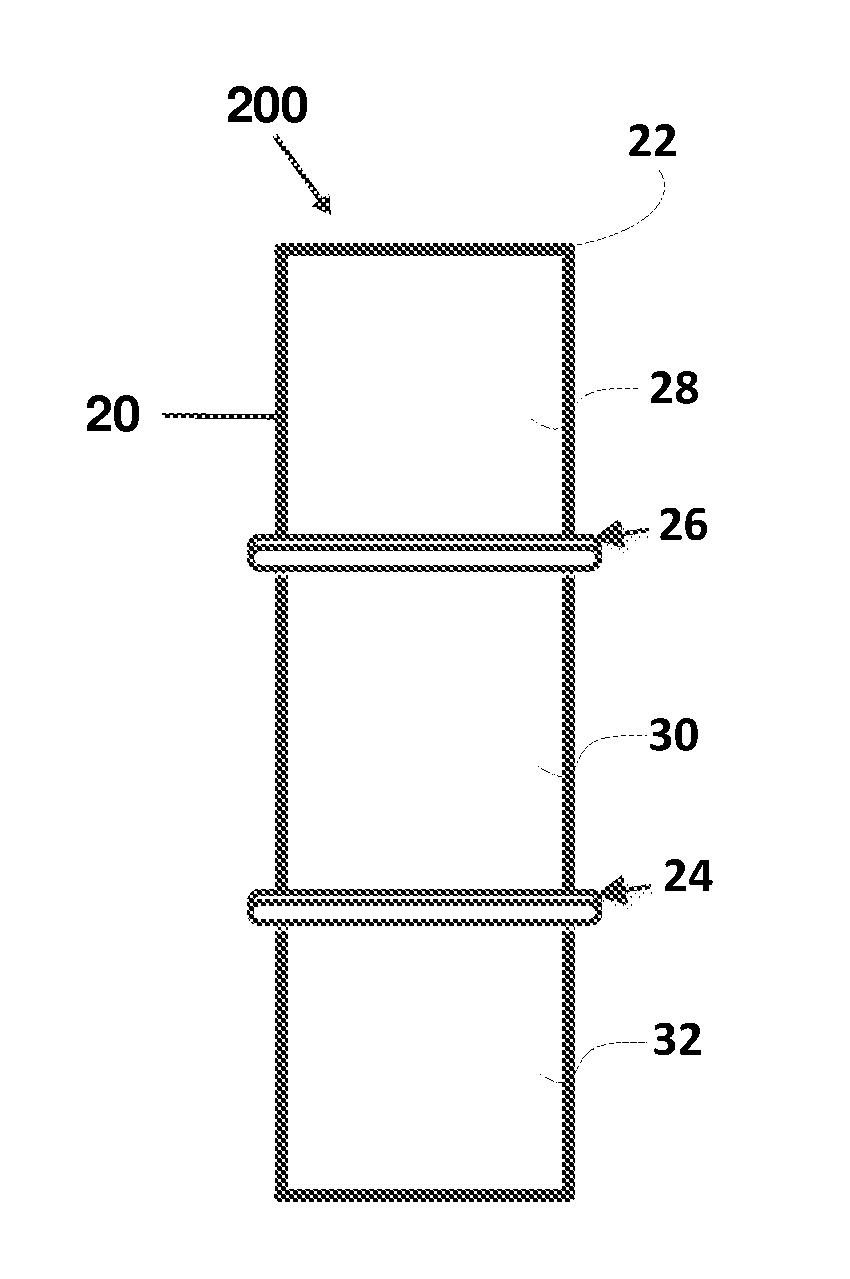

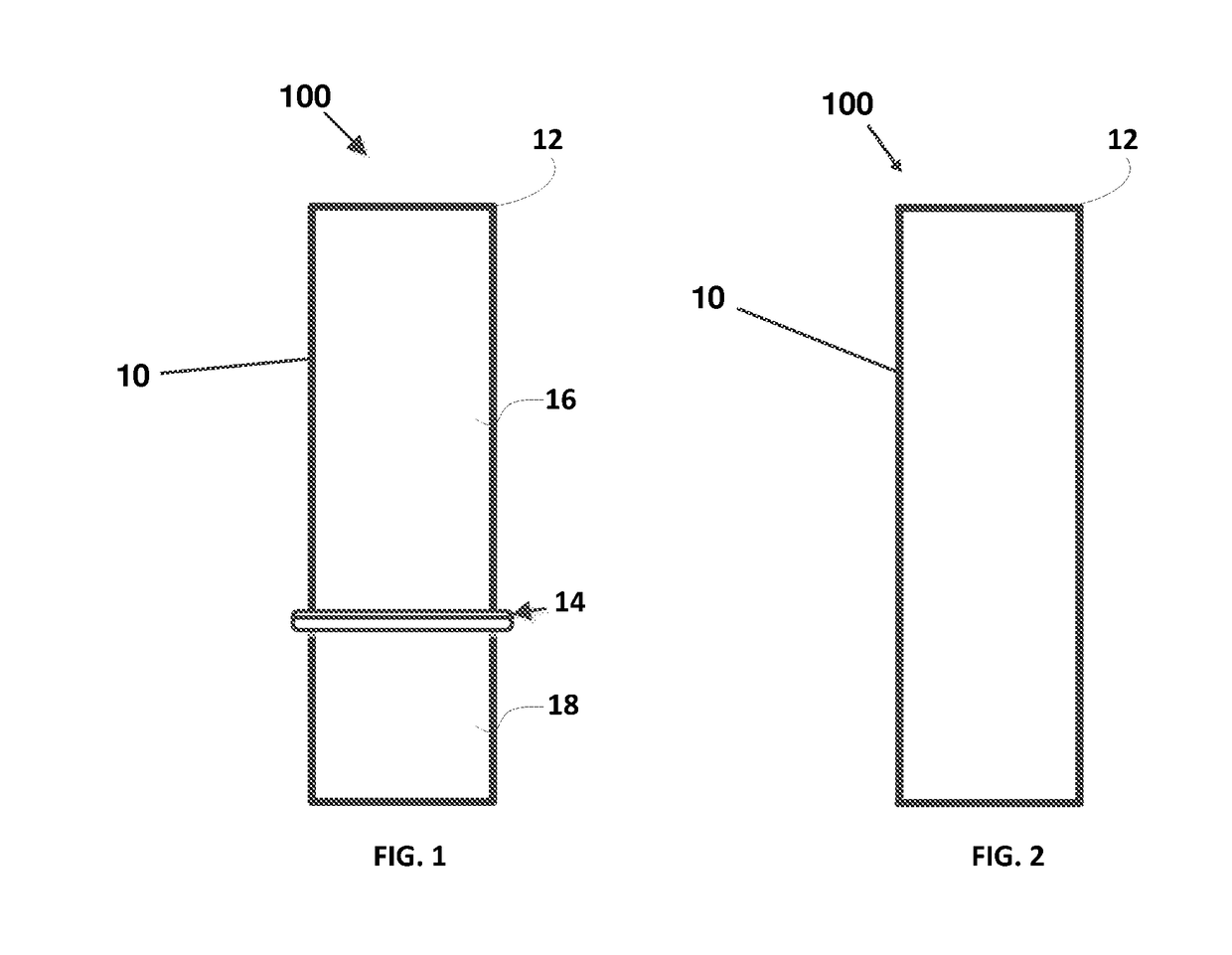

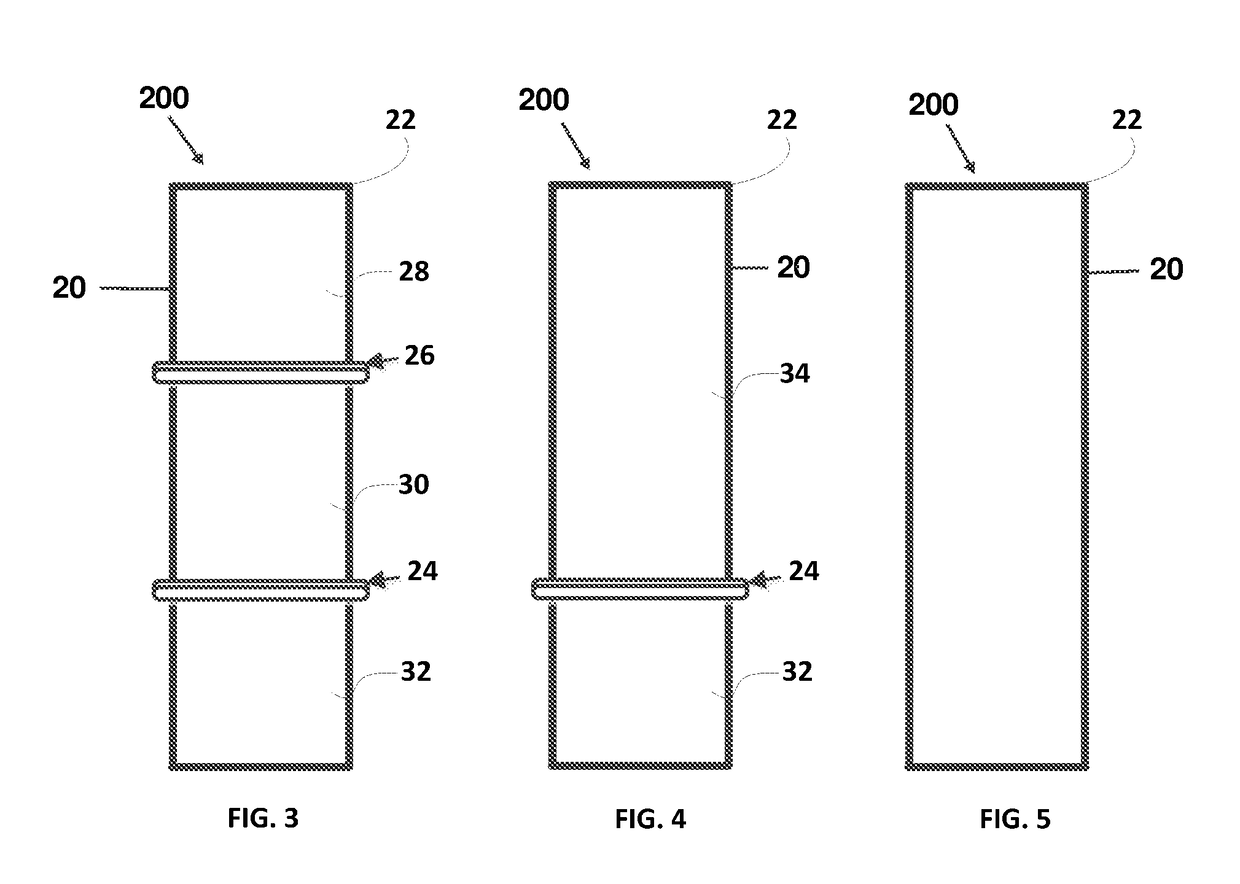

[0066]A repair kit including a three compartment sealed container was used to prepare a polymeric composite material. In this example, the sealed container was a Mylar® pouch and the removable dividers were clips. The reactive component was in one compartment, the resin component was in a second compartment, and a filler was in a third compartment. The reactive component was an isocyanate containing compound in liquid form, specifically a blend of aromatic diphenylmethane diisocyanate compounds. The resin component was a blend of hydroxyl-terminated compounds (polyols) and was also in liquid form, and the filler was recycled glass beads. Table 1 below provides the amount and density of the reactive component, the resin component, and the filler. As can be seen, the reactive component had a density about 9.5 lbs / gallon, the resin component had a density around 9 lbs. / gallon, and the filler had a density around 11 lbs. / gallon. Thus, the densities of the three components were relativel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com