Fabric containing a conductive yarn and apparatus for making the same

a technology of conductive yarn and fabric, which is applied in the direction of yarn, textiles and paper, etc., can solve the problems of affecting the quality of conductive yarn, and consuming a large amount of electricity and time to raise the temperature of air in space, so as to reduce the power consumption of conductive yarn of the present invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

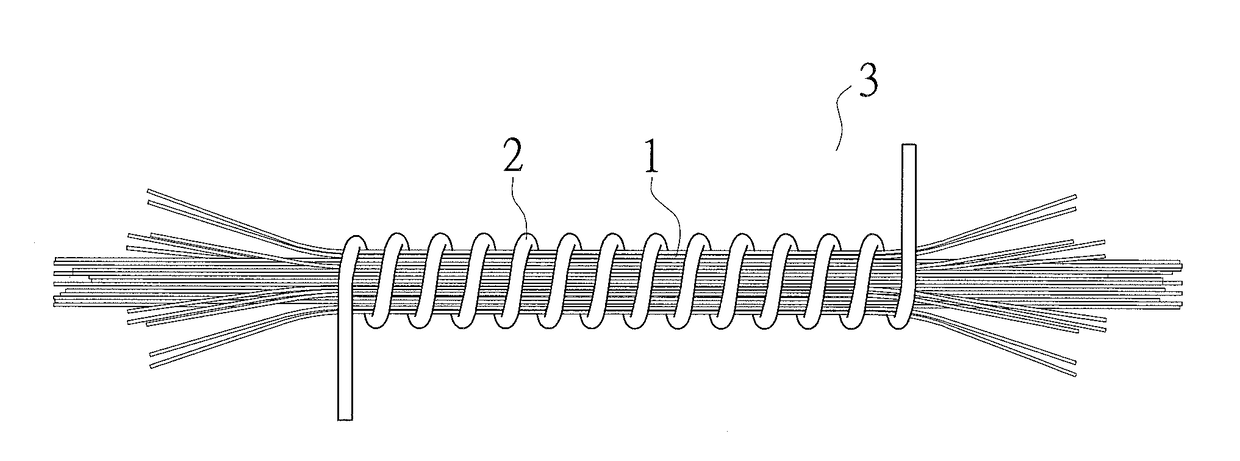

[0030]FIG. 2 to FIG. 4 show schematic views of a core thread, a fine metal thread, and a conductive yarn respectively according to the embodiment of the present invention. A conductive yarn comprises a non-conductive core thread 1 and a fine metal thread 2 wound around the surface of the core thread 1. The non-conductive core thread 1 is made of a plurality of fibers. The fine metal thread 2 is conductive and made of gold, silver, copper, tungsten, and molybdenum microfilament etc., for example. The diameter of the fine metal thread 2 ranges from 0.02 to 0.12 m / m. The fine metal thread 2 is guided by an apparatus to wind around the surface of the core thread 1 in a spiral form so as to form an elastic and flexible conductive yarn 3.

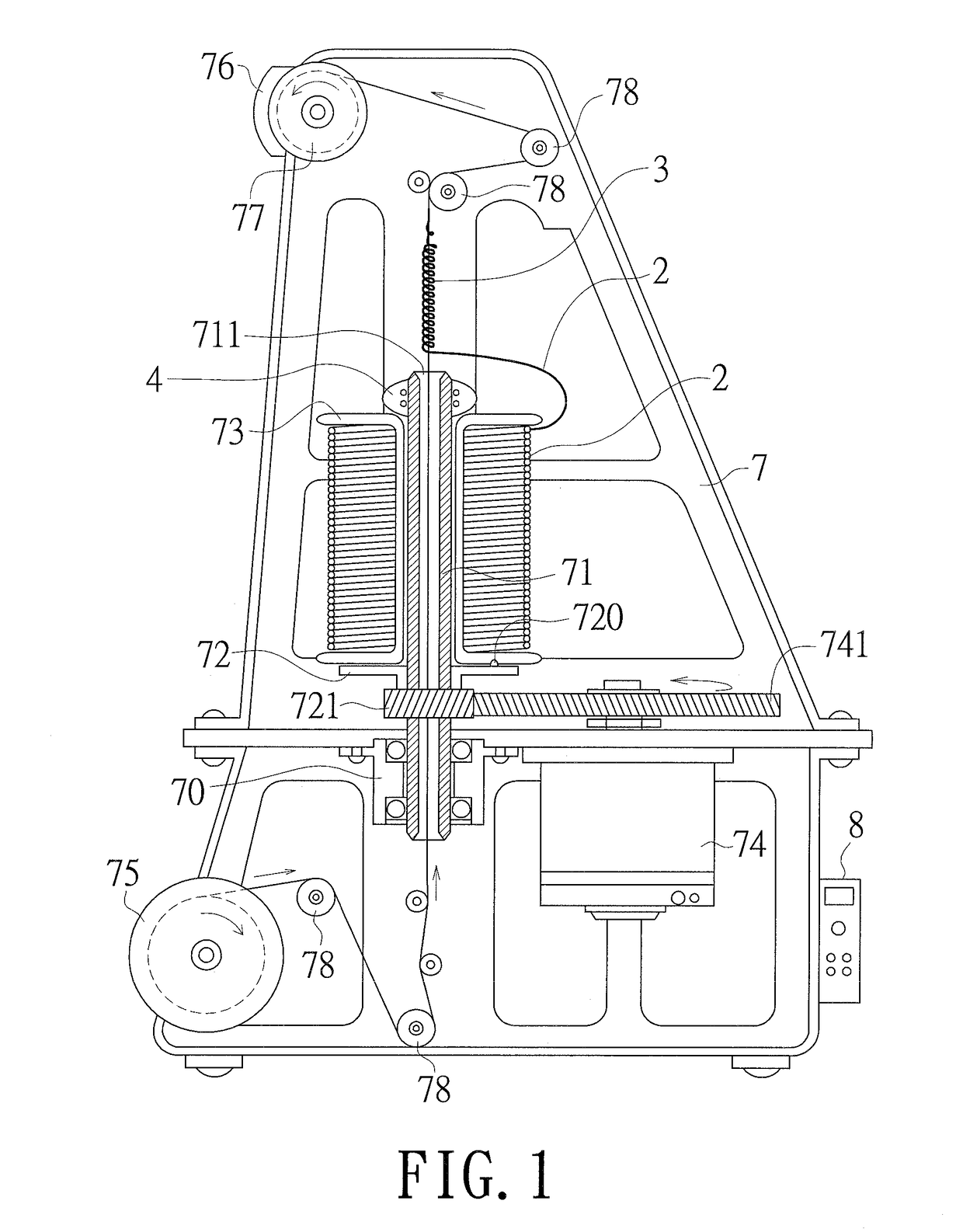

[0031]The apparatus for making the conductive yarn according to the embodiment of the present invention is shown in FIG. 1. The apparatus comprises a base station 7, an axle seat 70, an axle 71, a base 72, a turning wheel 721, a spool 73, a first power so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

| non-conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com