Time-lapse infrared thermography system and method for damage detection in large-scale objects

a time-lapse infrared thermography and large-scale object technology, applied in the field of time-lapse infrared thermography system and large-scale object damage detection, can solve the problems of insufficient heat for a large object, inability to adequately provide active thermography with a user supplied heat source, and inability to accurately measure internal defects of objects, etc., to achieve the effect of accurate internal condition measurement, improved maintenance efficiency and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

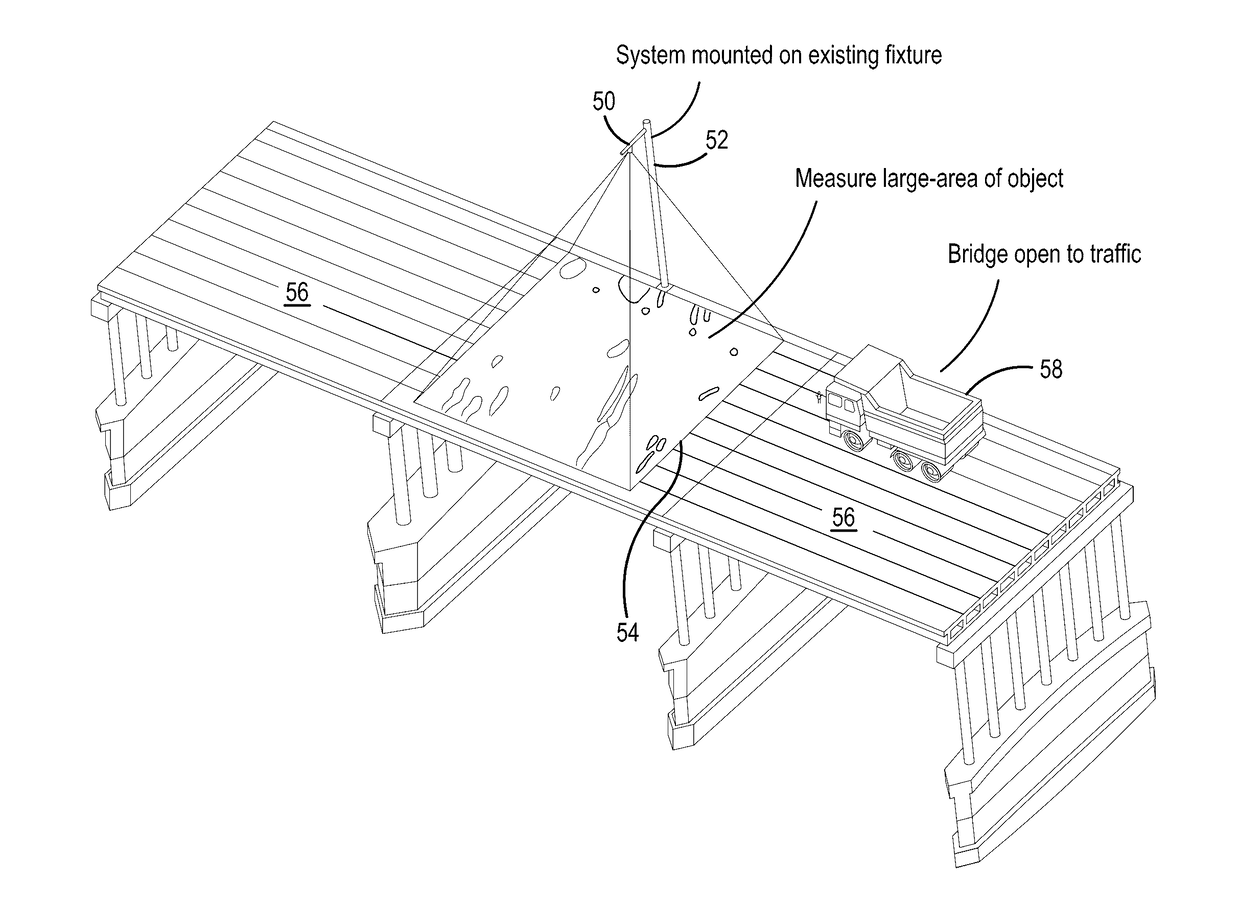

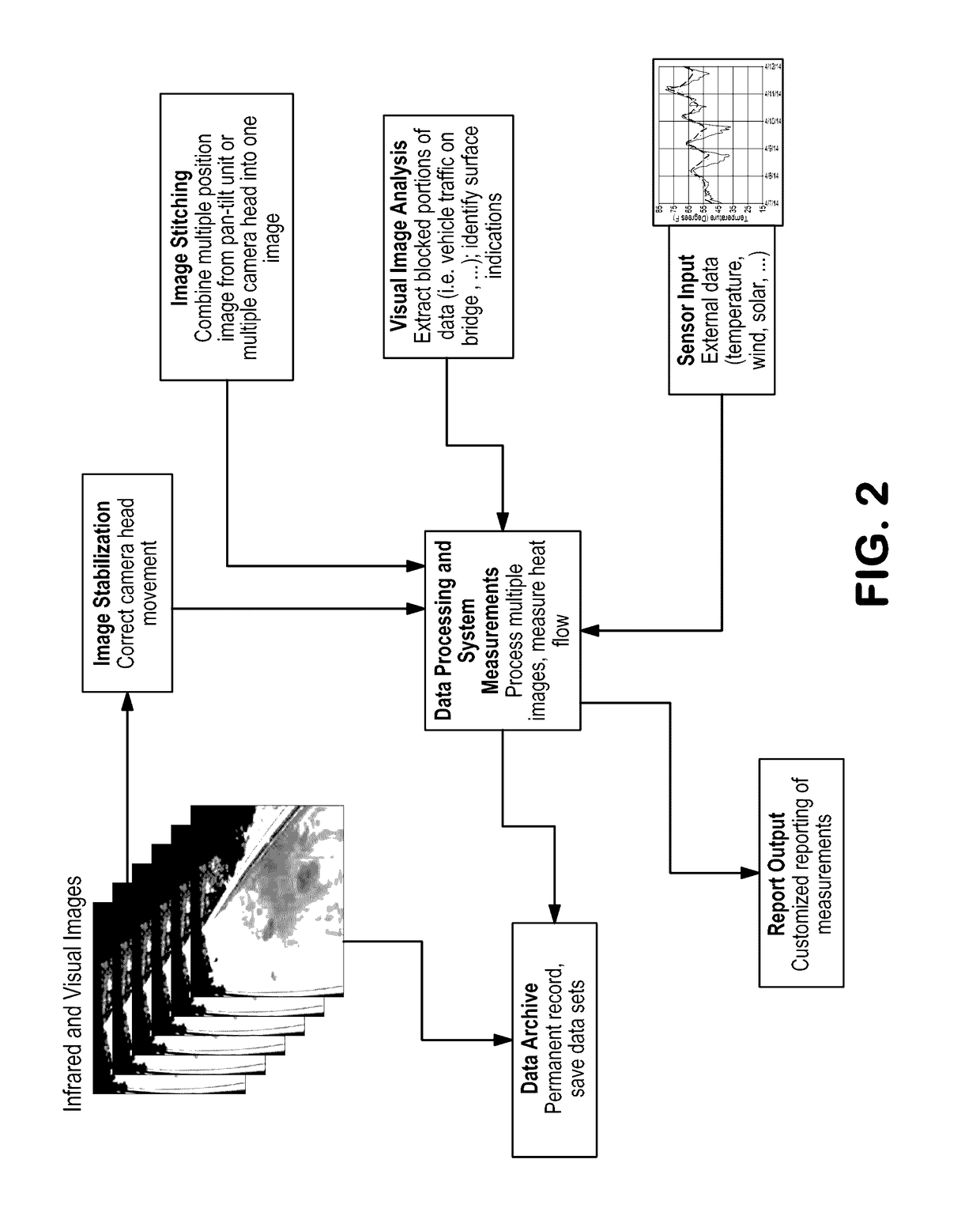

[0030]The infrared and visual measurement and data processing system of the invention is, in particular, useful for measuring objects or structures of large scale, i.e., of substantial size, to determine the location of internal defects in the objects and includes the taking of multiple infrared images and multiple visual images over an extended period of time in order to improve the detection and measurements of defects and overcome the limitations of conventional infrared thermography.

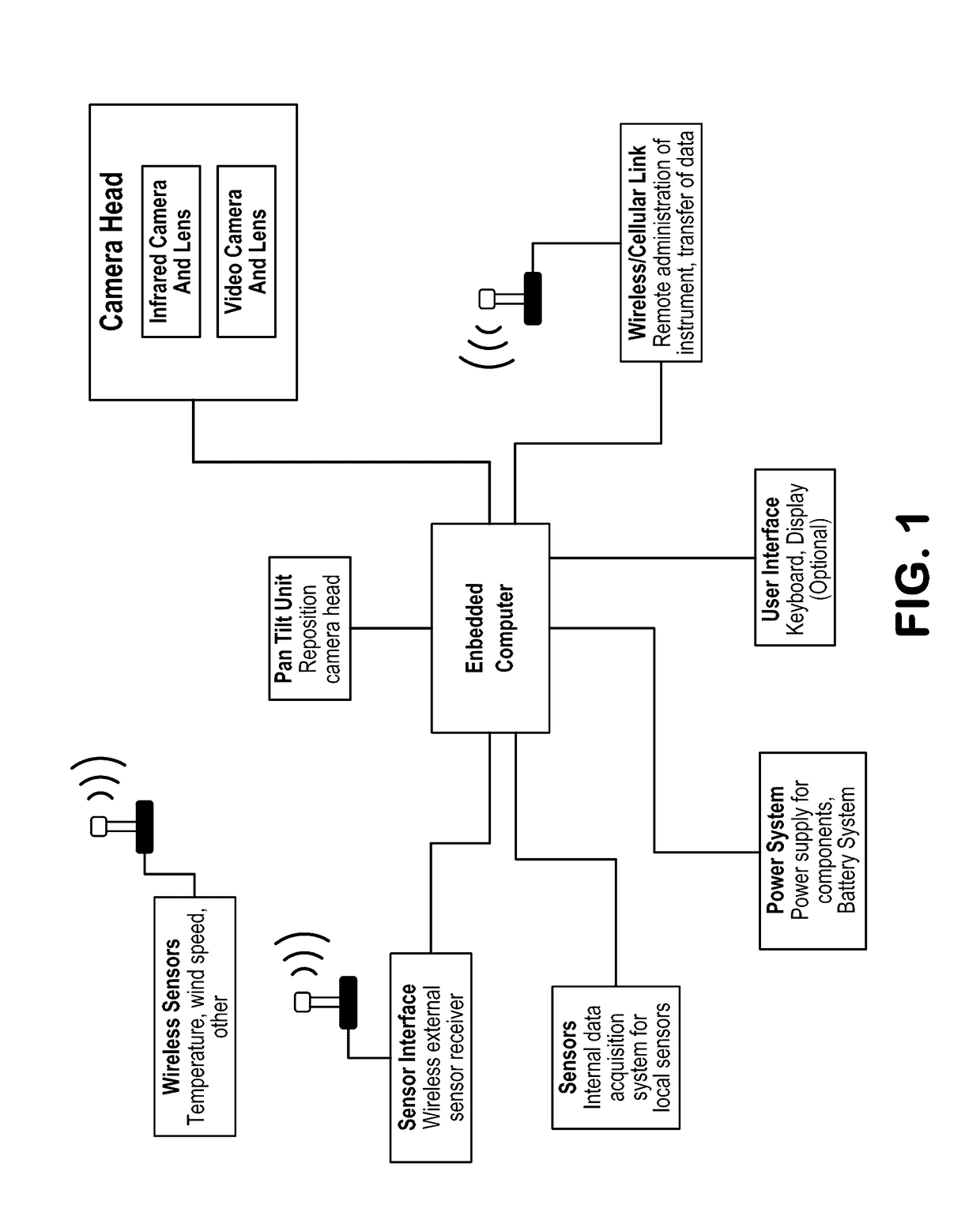

[0031]Hardware Components

[0032]Described below are hardware components of presently preferred embodiments of the invention. The primary hardware components of a preferred embodiment are shown in FIGS. 1, 3a-3b and 4a-4f, and are described in detail below. However, it is understood that other hardware components and configurations may be used without departing from the scope of the invention.

[0033]Infrared Camera and Lens

[0034]An infrared (IR) camera is used to measure radiant flux or temperature of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com