Apparatus for indirect atmospheric pressure plasma processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

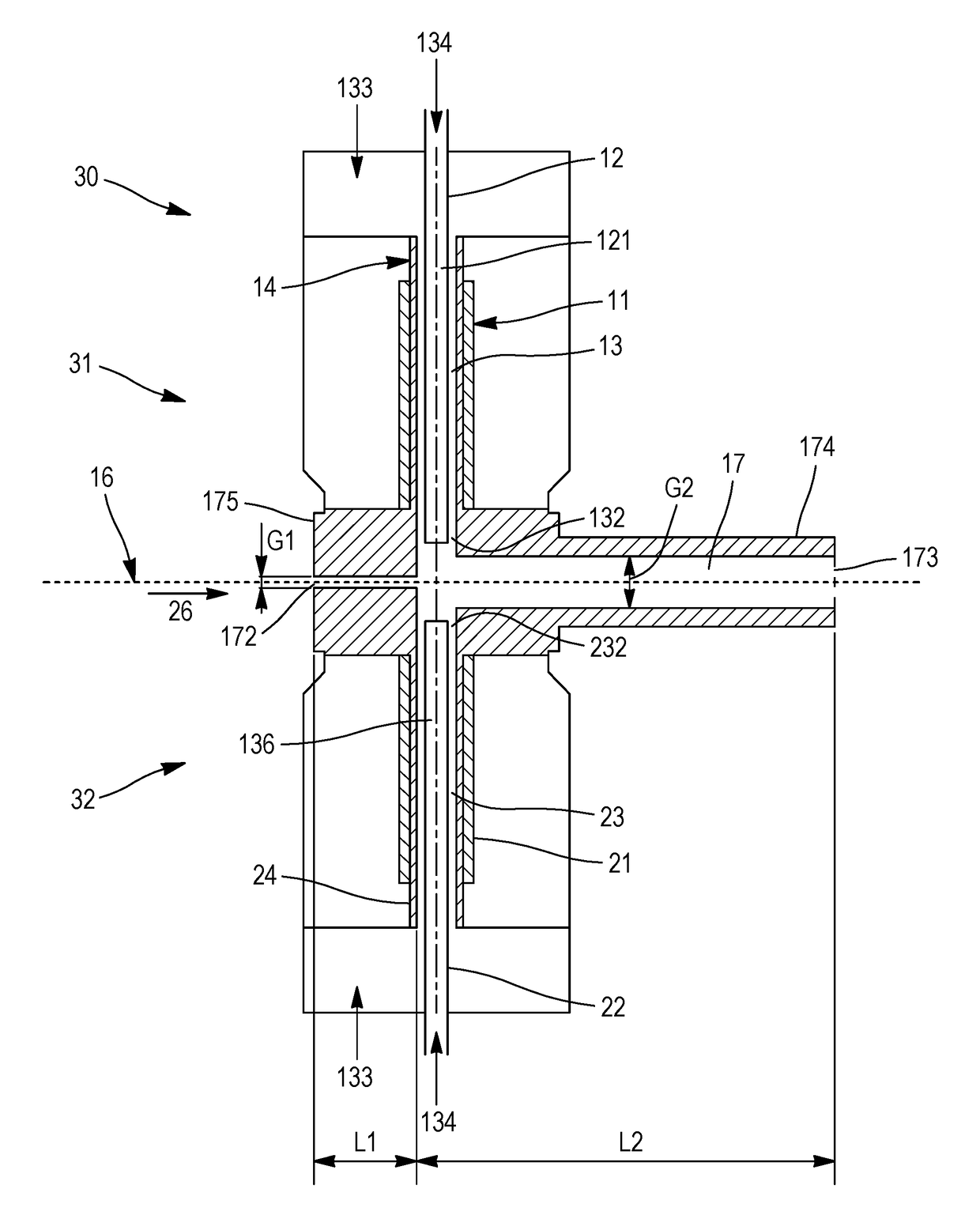

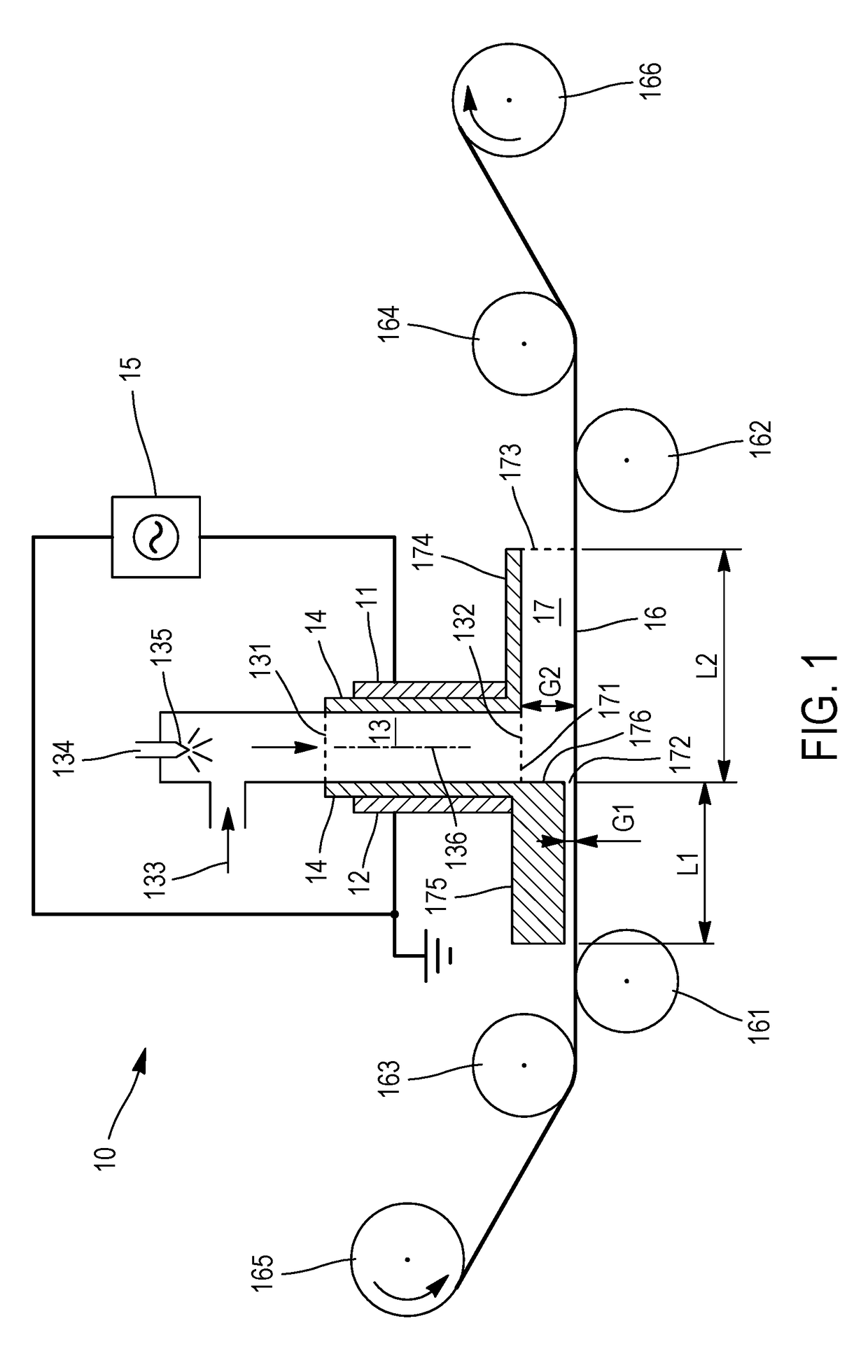

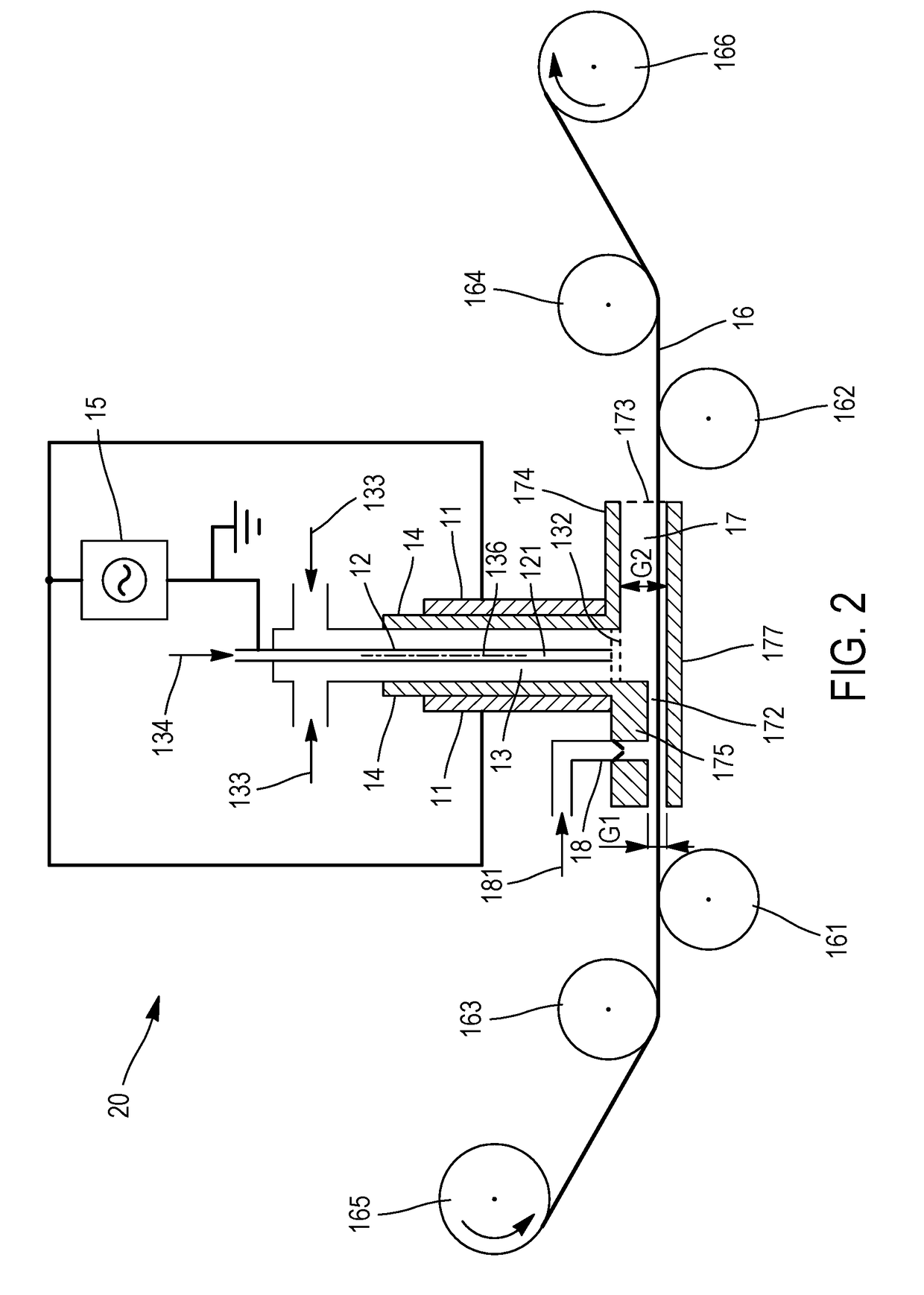

[0020]Referring to FIG. 1, an apparatus 10 for plasma processing of a continuous substrate 16, such as but not limited to films and foils, comprises a pair of oppositely arranged electrodes 11 and 12. Electrodes 11 and 12 are planar and extend parallel to each other. They are spaced apart to define a plasma discharge chamber 13 between the electrodes 11, 12. Advantageously, dielectric layers 14 cover one or both electrodes 11, 12 at the side facing the plasma discharge chamber 13. In such case, the dielectric layers 14 form walls of the chamber 13. Dielectric materials include borosilicate glass, quartz, and alumina.

[0021]Chamber 13 comprises an inlet 131 through which a plasma forming gas 133 is made to enter the chamber. The plasma forming gas is one which is able to create a plasma discharge in chamber 13 under an electric field generated by the electrodes 11, 12. The plasma forming gas is advantageously a non-oxidizing gas, advantageously a gas which is substantially oxygen-free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com