Composition and method for additive manufacturing of an object

a technology of additive manufacturing and object, applied in the field of composition and method of additive manufacturing of objects, to achieve the effects of high hdt, good durability and stability, and high toughness

Inactive Publication Date: 2017-06-22

STRATASYS LTD

View PDF5 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

The present inventors have created a modeling material that can absorb high amounts of water and has high impact resistance and thermal resistance. This material can be used in 3D printing to create objects with improved performance.

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

examples

[0371]Reference is now made to the following examples, which together with the above descriptions illustrate some embodiments of the invention in a non limiting fashion.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Login to View More

Abstract

Formulations and methods employing these formulation for fabricating an object by additive manufacturing, such as three-dimensional inkjet printing are provided. The formulations comprise at least 50 weight percents of hydrophilic curable materials, and upon curing, provide a material that is characterized by water absorbance of at least 5%, and by high HDT and impact resistance values. Objects containing cured material made of these formulations are also provided.

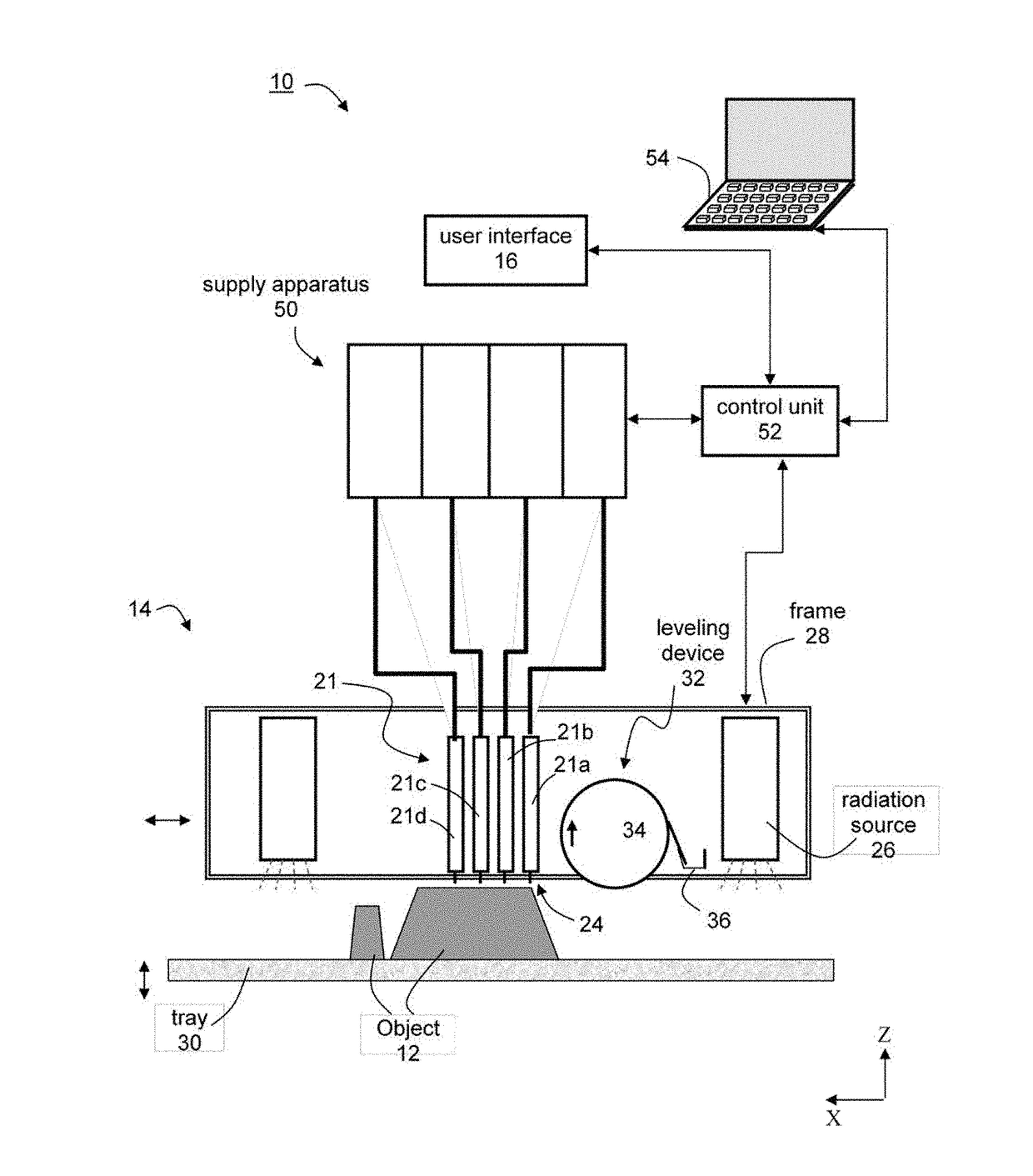

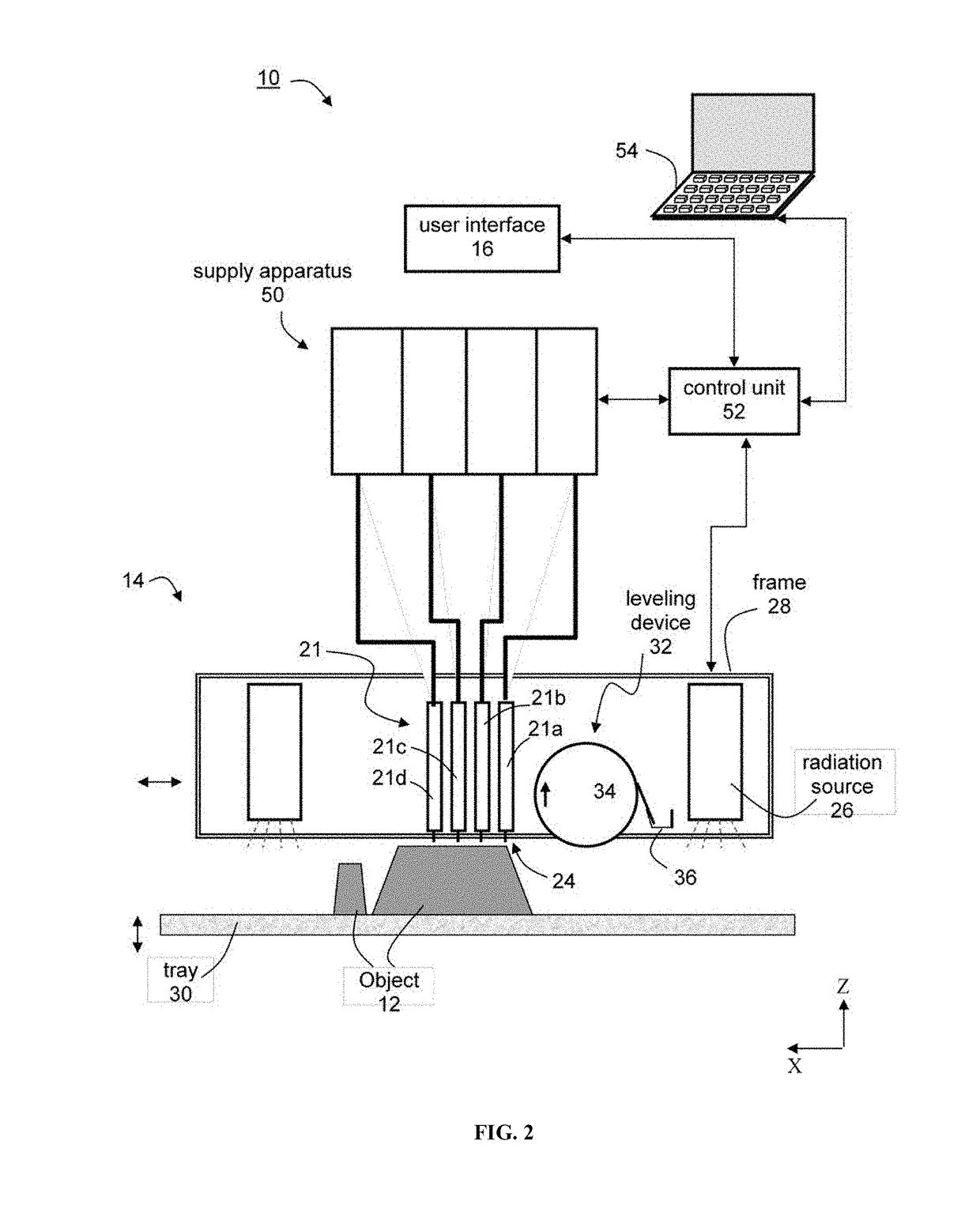

Description

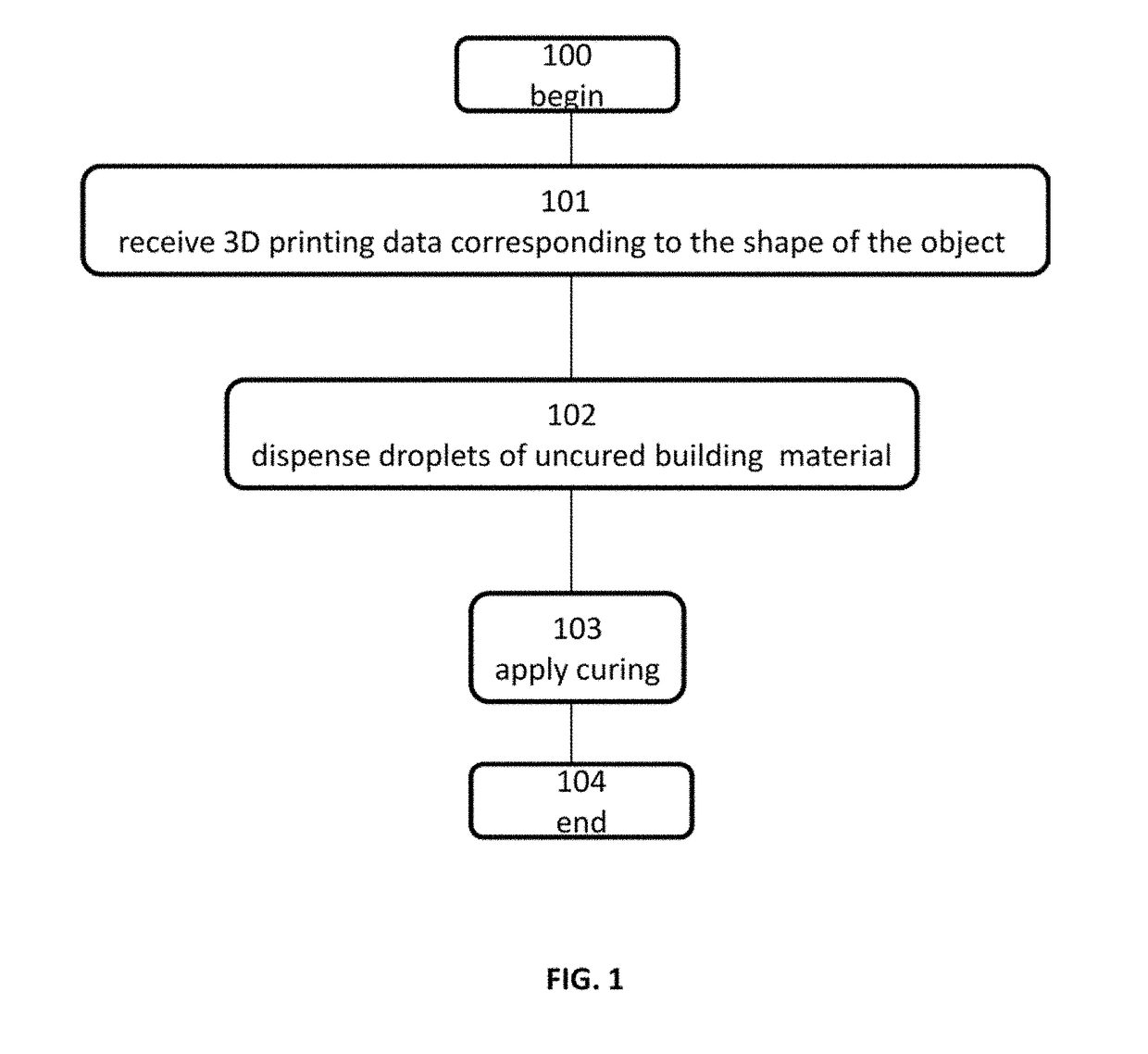

RELATED APPLICATION[0001]This application claims the benefit of priority from U.S. Application No. 61 / 937,773, filed on Feb. 10, 2014, the contents of which are hereby incorporated by reference as if fully set forth herein.FIELD AND BACKGROUND OF THE INVENTION[0002]The present invention, in some embodiments thereof, relates to Additive Manufacturing (AM) of an object, and, more particularly, but not exclusively, to a composition and method for additive manufacturing of an object which exhibits desirable mechanical properties.[0003]Additive manufacturing is generally a process in which a three-dimensional (3D) object is manufactured utilizing a computer model of the objects. Such a process is used in various fields, such as design related fields for purposes of visualization, demonstration and mechanical prototyping, as well as for rapid manufacturing (RM).[0004]The basic operation of any AM system consists of slicing a three-dimensional computer model into thin cross sections, trans...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): B29C67/00B33Y10/00B33Y70/00B29C35/08

CPCB29C67/007B29C35/0805B33Y10/00B29K2995/0089B29C2035/0827B29K2995/0092B33Y70/00C09D11/101C09D11/30B29C64/112B29C64/129C09D4/00

Inventor DIKOVSKY, DANIELHIRSCH, SHAI

Owner STRATASYS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com