Electrochemical polishing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

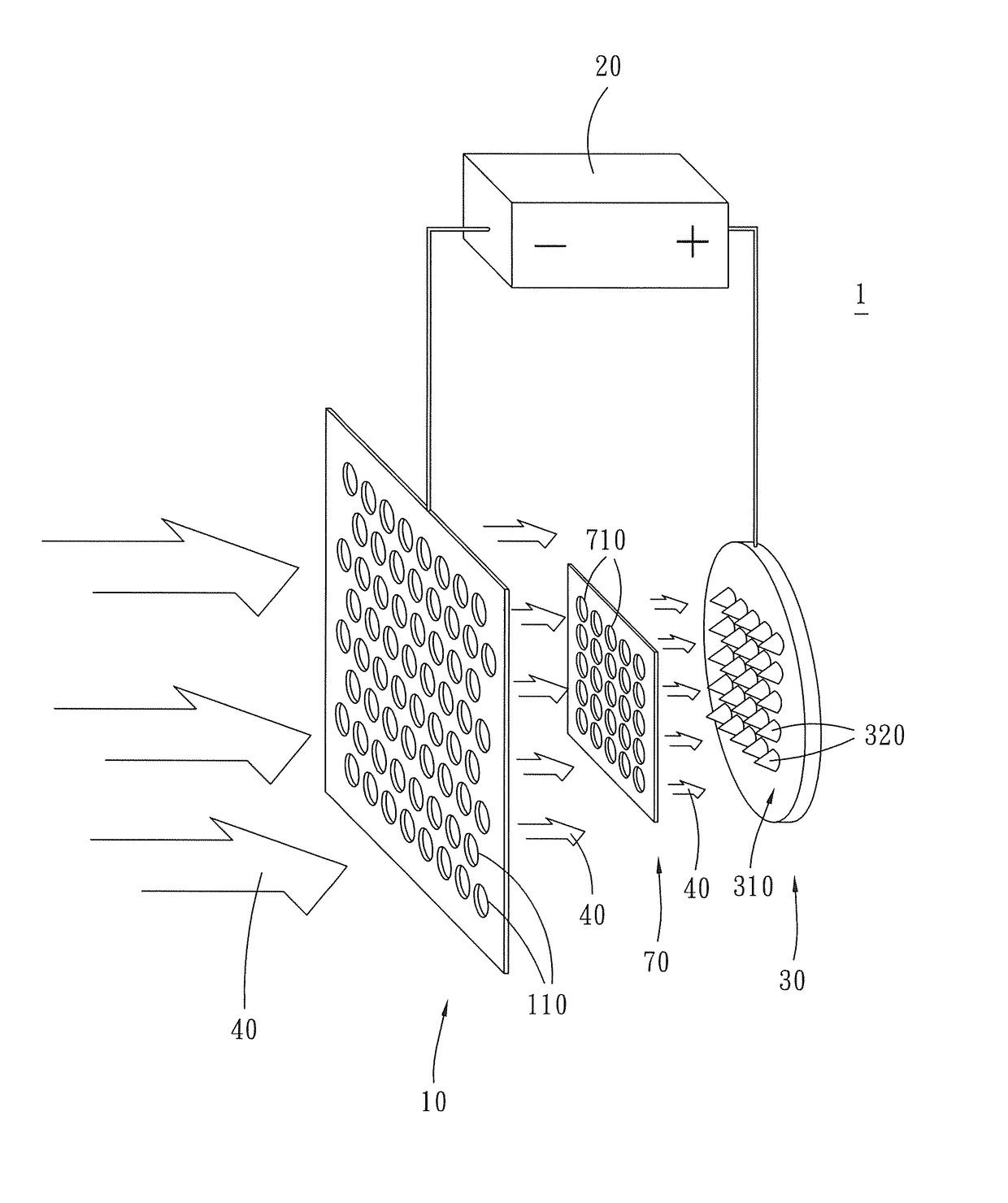

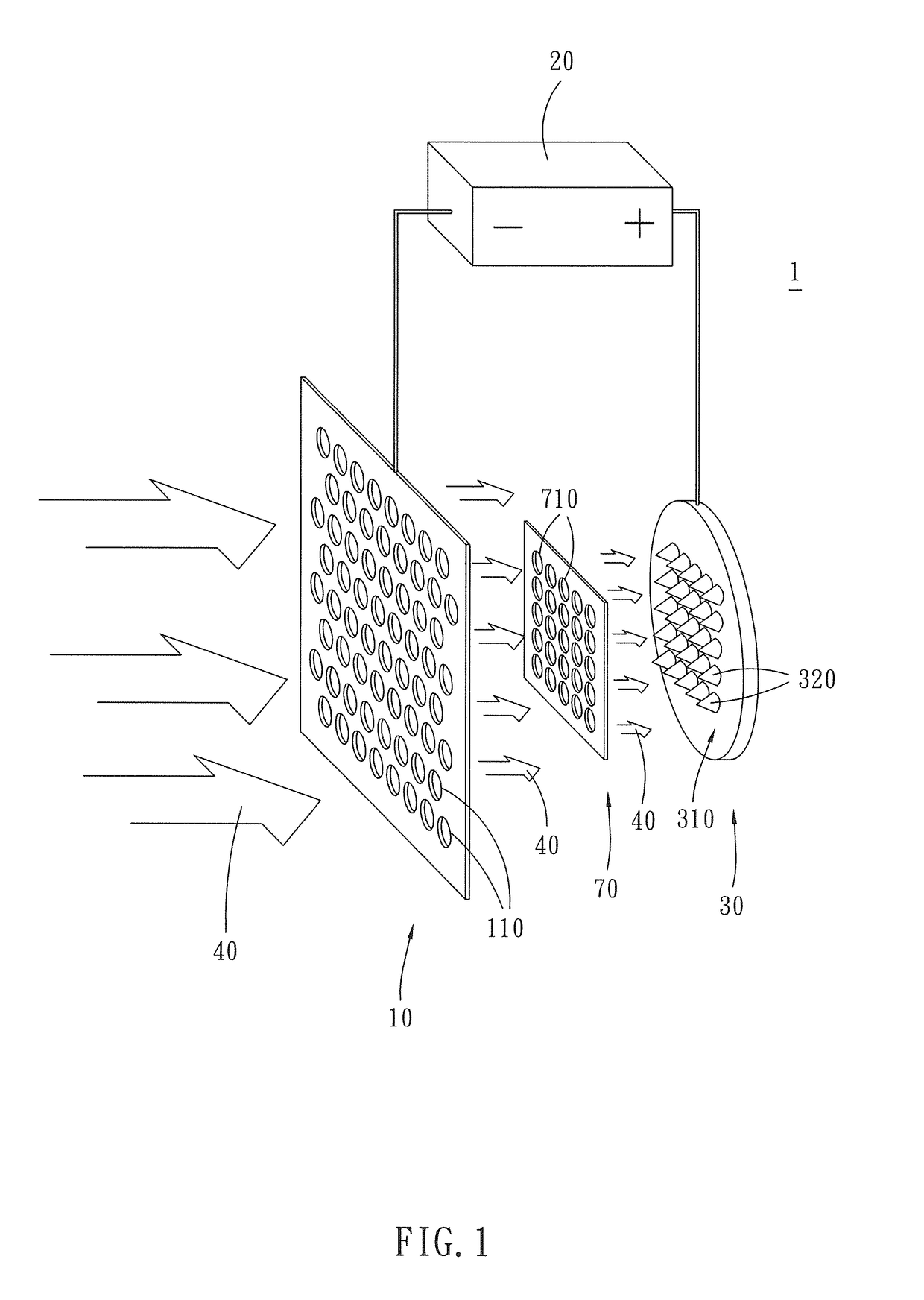

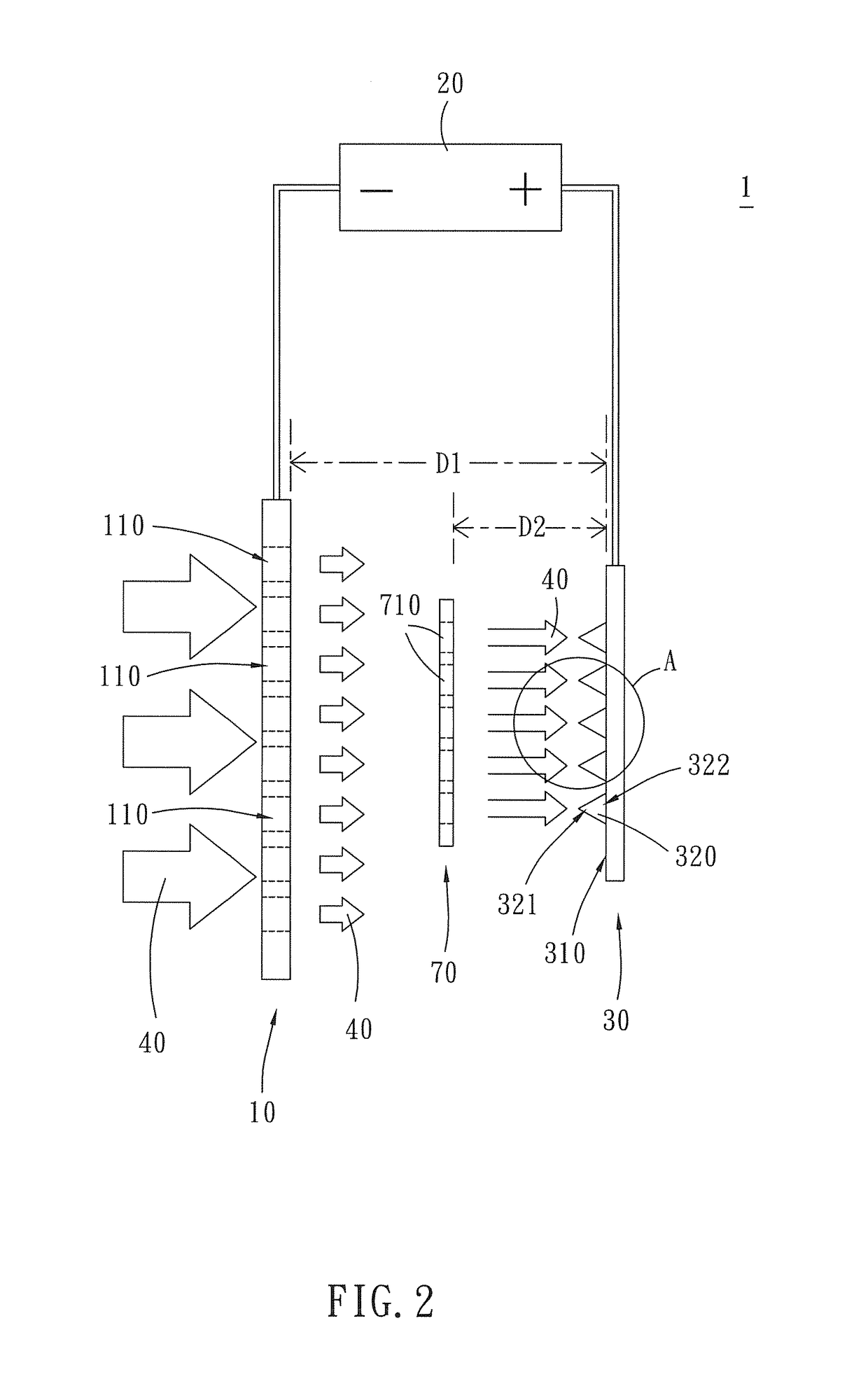

[0018]Please refer to FIG. 1 and FIG. 2, which show a schematic diagram and a cross-sectional view of the electrochemical polishing apparatus according to the present invention. As shown in the figures, the present invention provides an electrochemical polishing apparatus 1 used for polishing a workpiece 30 having at least one sharp object 320. The electrochemical polishing apparatus 1 comprises an electrode 10 and a power supply unit 20. The electrode 10 corresponds to a surface 310 of the workpiece 30. The electrode 10 and the workpiece 30 are spaced by a distance D1. According to an embodiment of the present invention, the distance D1 is approximately 8 to 15 millimeters (mm). The electrode 10 has a plurality of hollow-out parts 110 corresponding to the surface 310 of the workpiece 30. The plurality of hollow-out parts 110 of the electrode 10 allow an electrolyte 40 to flow through and to the sharp objects 320 of the workpiece 30. By driving the electrolyte 40 to flow through the...

second embodiment

[0024]Please refer to FIG. 4, which shows a schematic diagram of the electrochemical polishing apparatus according to the present invention. As shown in the figure, according to the present embodiment, the electrochemical polishing apparatus 1 further comprises an electrolyte driving unit 50 and an electrolyte tank 60. The electrolyte tank 60 accommodates the electrode 10, the workpiece 30, and the electrolyte driving unit 50. The electrolyte 40 fills the electrolyte tank 60. According to the present embodiment, the electrolyte driving unit 50 is an electrolyte disturbing device 50A, which can spin and disturb the electrolyte 40. By driving the electrolyte 40 to flow, the electrolyte 40 is driven to pass through the plurality of hollow-out parts 110 of the electrode 10 and the plurality of hollow-out parts 710 of the flow equalizer 70, and flow to the plurality of sharp objects 320 of the workpiece 30.

third embodiment

[0025]Please refer to FIG. 5, which shows a schematic diagram of the electrochemical polishing apparatus according to the present invention. As shown in the figure, according to the present embodiment, the electrolyte driving unit 50 is an electrolyte projecting device 50B, which projects the electrolyte 40 to the electrode 10 and thus driving the electrolyte 40 to pass through the plurality of hollow-out parts 110 of the electrode 10 and the plurality of hollow-out parts 710 of the flow equalizer 70, and flow to the plurality of sharp objects 320 of the workpiece 30.

[0026]Please refer to FIG. 6A and FIG. 6B, which show schematic diagrams of the electrode according to the first and second embodiments of the present invention. As shown in the figures, the electrode 10 is a metal plate having a plurality of hollow-out parts 110. According to the embodiment shown in FIG. 6A, the arrangement of the plurality of hollow-out parts 110 of the electrode 10 is symmetric and rectangular. In ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com