Method for manufacturing medicated chewing gum without cooling

a manufacturing method and gum technology, applied in the field of chewing gum manufacturing, can solve the problems of affecting the chemical stability of the therapeutic agent, erode the effect of the active,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0127]Chitosan Chewing Gum

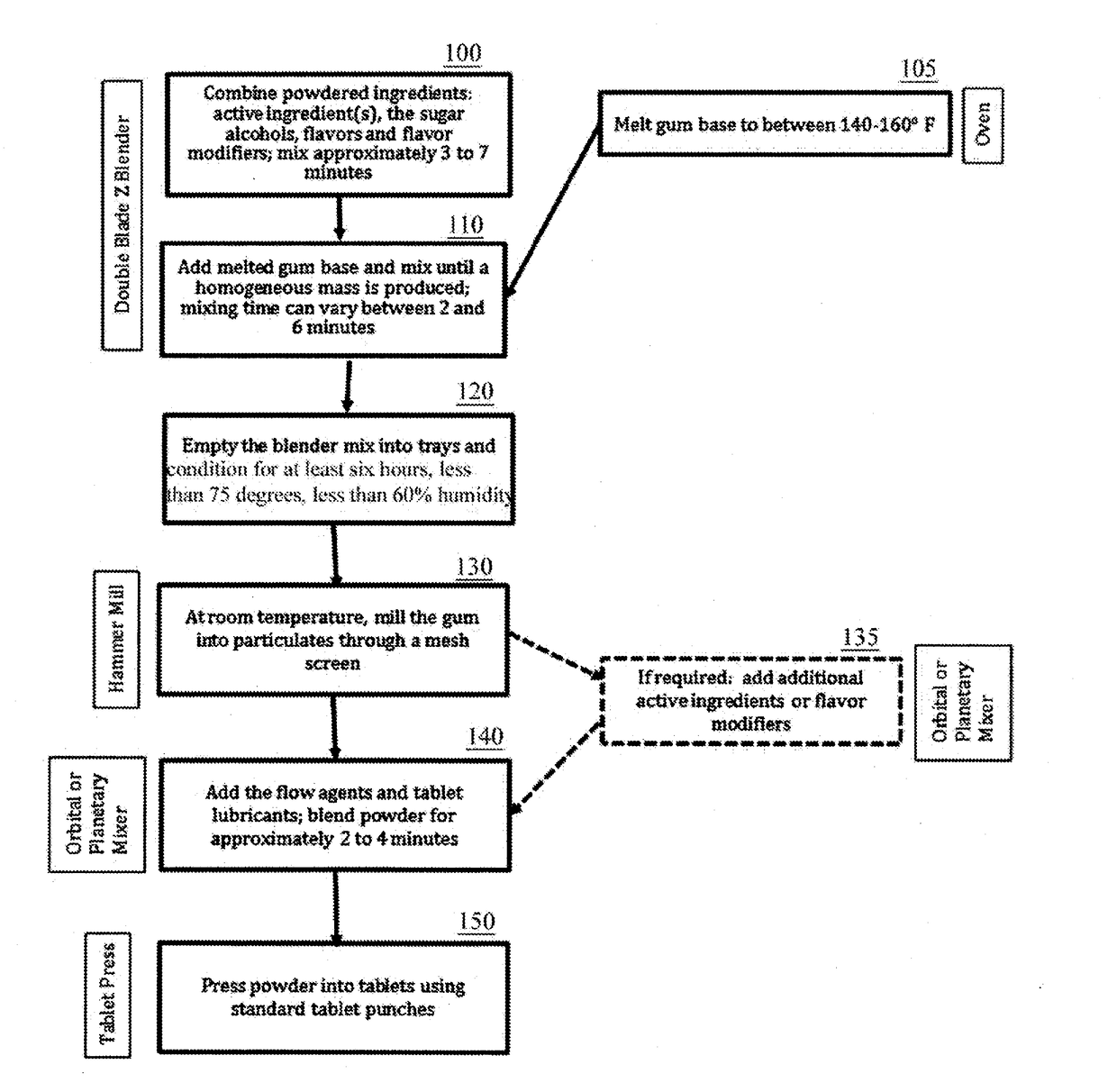

[0128]The foregoing method of FIG. 1 has been used successfully to produce a tableted gum with a powdered active ingredient, for example chitosan, using the relative amounts of constituents (sugar alcohol, gum base, flavoring, active ingredient / chitosan, tableting lubricants and powder flow agents, and sweeteners) as shown in Table 1:

TABLE 1Weight %OptimalRangeWeight %A sugar alcohol or a blend of sugar alcohols42.4-75.364.0that can include one or more of the following:sorbitol, isomalt, xylitol, maltitol, mannitol orerythritolGum Base20.0-30.025.7Flavoring in liquid and powder 2.0-12.03.3Active ingredient(s) - chitosan 1.0-20.02.5Tableting lubricants and powder flow agents1.5-5.04.0Intensive sweeteners0.2-0.60.5Total100.0

example 2

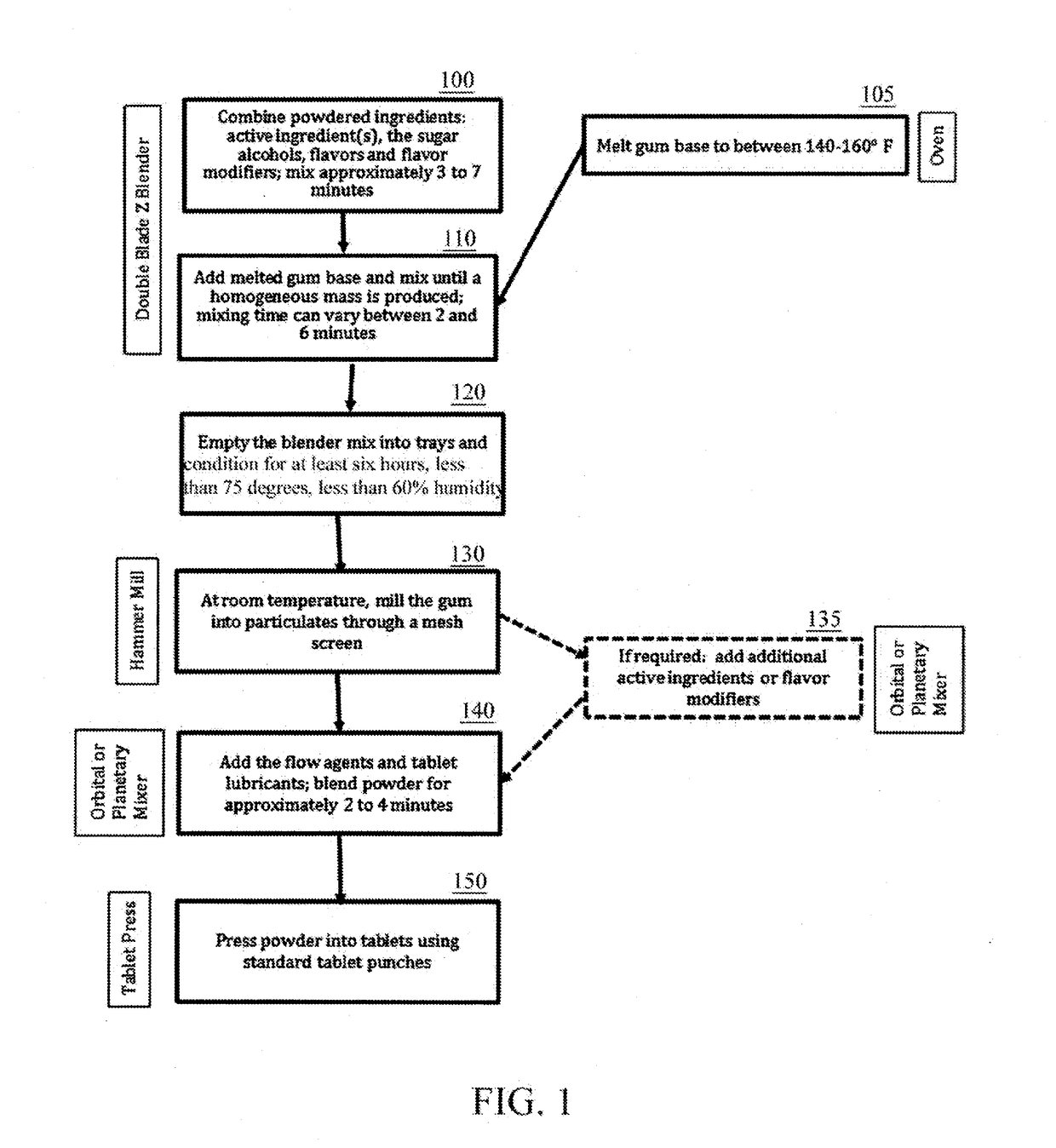

[0129]Caffeine Chewing Gum

[0130]The foregoing method of FIG. 2 has been used successfully to produce a tableted gum with a powdered active ingredient, for example caffeine, using the relative amounts of constituents (sugar, gum base, flavoring, active ingredient / caffeine, tableting lubricants and powder flow agents, and sweeteners) as shown in Table 2:

TABLE 2Weight %OptimalRangeWeight %A sugar or a blend of sugars that can include55.0-70.059.6one or more of the following: dextrose,sucrose, fructose, glucoseGum Base20.0-30.021.2Flavoring in liquid and powder 8.0-15.09.8Active ingredient(s) - caffeine 1.0-10.04.7Tableting lubricants and powder flow agents2.6-5.03.7Intensive sweeteners0.2-1.51.0Total100.0

example 3

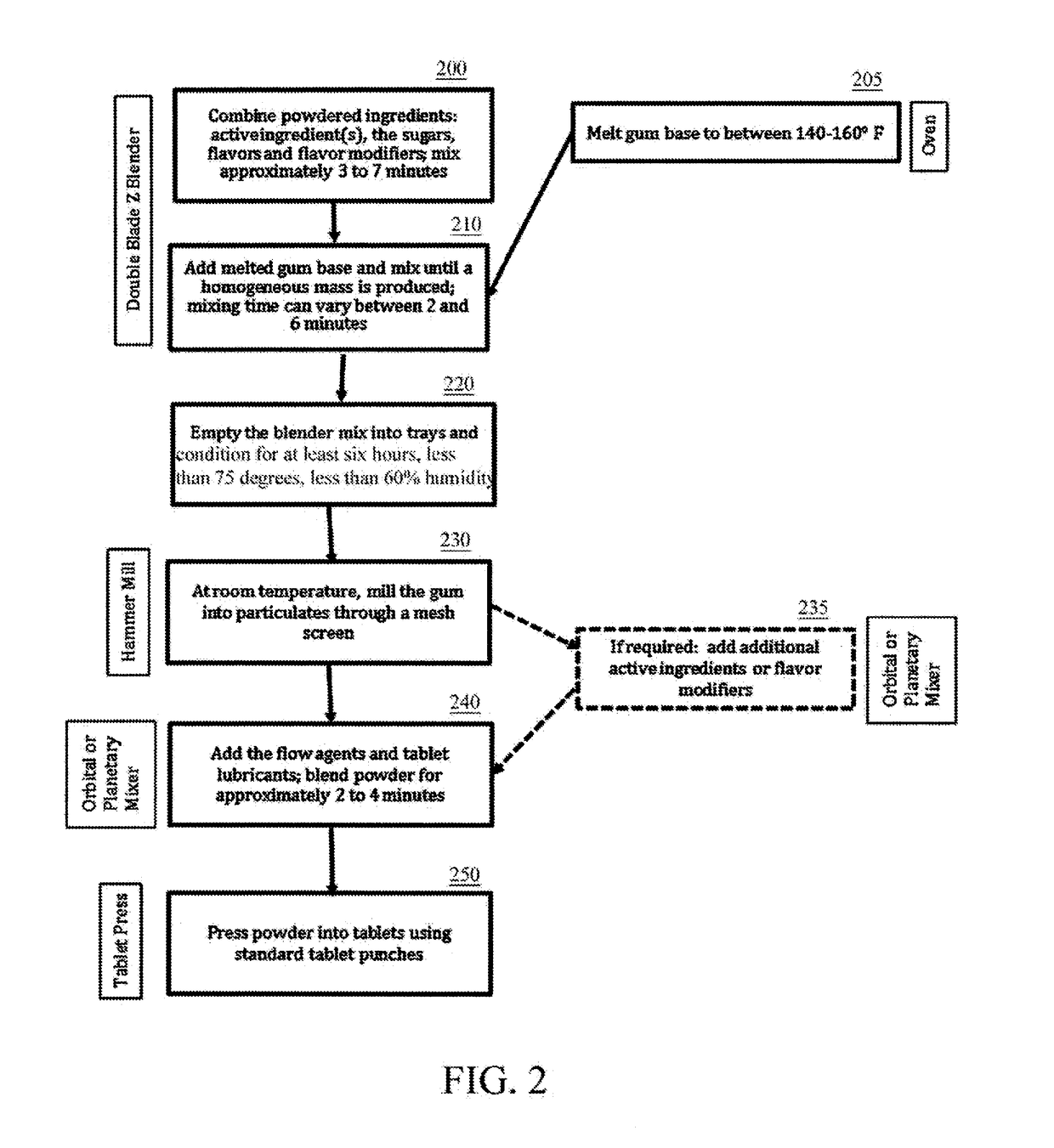

[0131]Hemp Oil Chewing Gum

[0132]The foregoing method of FIG. 3 has been used successfully to produce a tableted gum with an oil-form active ingredient, for example concentrated hemp oil that delivers cannabidiol (CBD) or with a resinous oil that delivers tetrahydrocannabinol (THC). The relative amounts of constituents (sugar alcohol, gum base, flavoring, active ingredient / hemp oil, tableting lubricants and powder flow agents, and sweeteners) as shown in Table 3:

TABLE 3Weight %OptimalRangeWeight %A sugar alcohol or a blend of sugar alcohols that48.4-68.857.8can include one or more of the following:sorbitol, isomalt, xylitol, maltitol, mannitol orerythritolGum Base20.0-30.028.5Flavoring in liquid and powder 9.0-11.06.9Active ingredient(s) - hemp oil 0.5-10.02.5Tableting lubricants and powder flow agents1.5-5.03.8Intensive sweeteners0.2-0.60.5Total100.0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com