Throttle unit and a static pressure bearing device equipped with the throttle unit, and a method of manufacturing a grooved block

a technology of static pressure bearing and throttle unit, which is applied in the direction of manufacturing tools, mechanical equipment, rotary machine parts, etc., can solve the problems of difficult cleaning of the unit, high cost of preparing such a needle, and the strength of the restriction may change, so as to reduce the weight of parts, and improve the quality of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

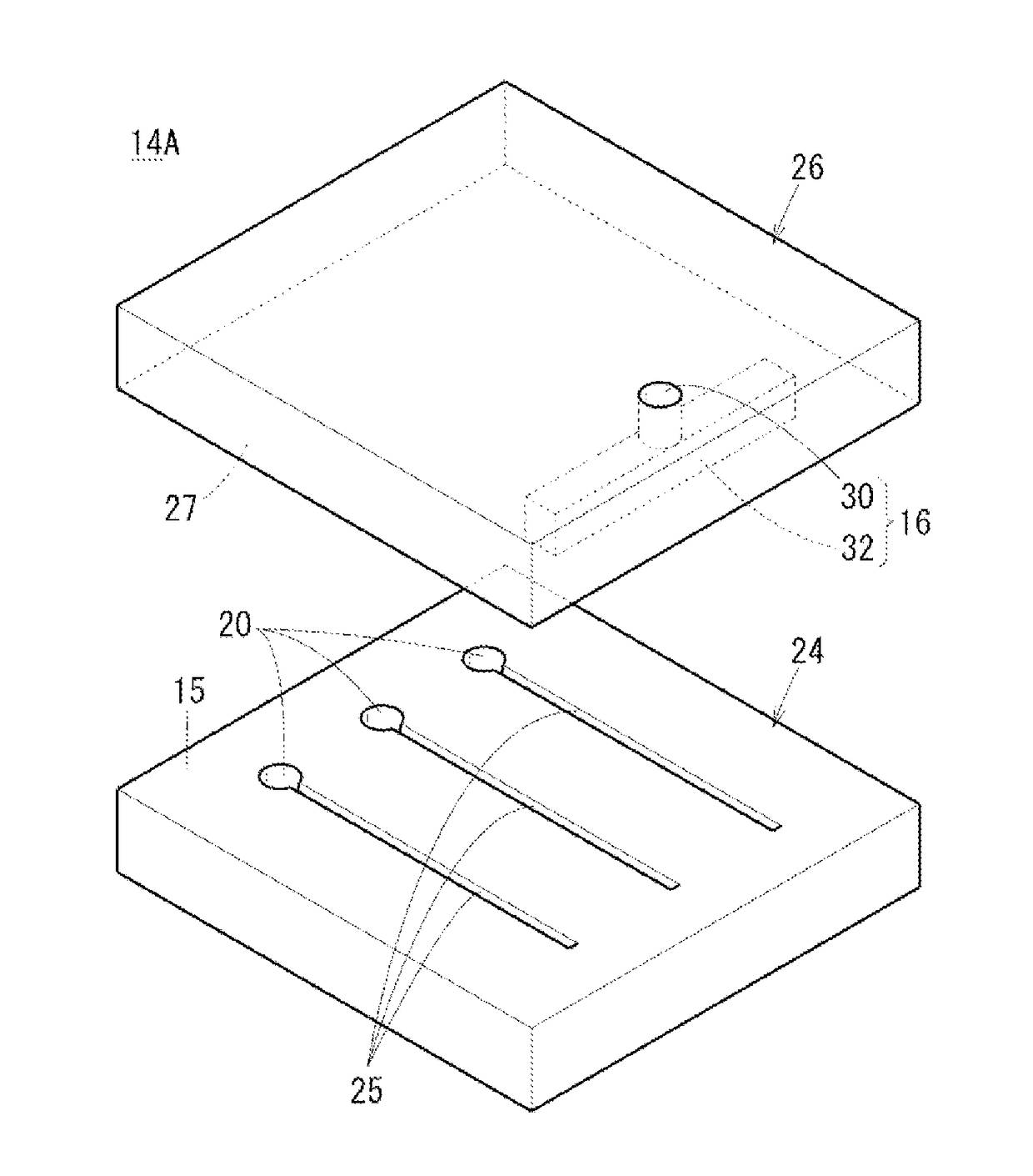

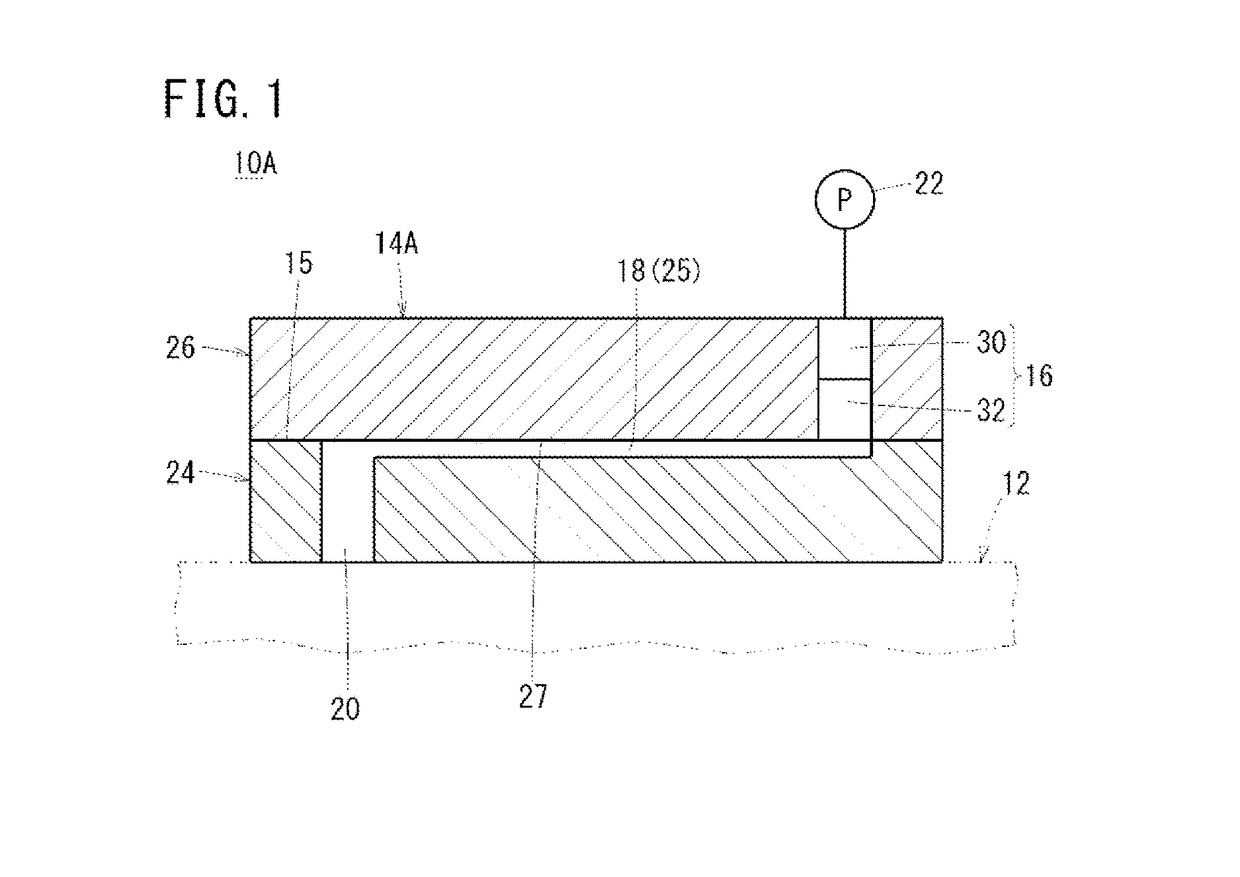

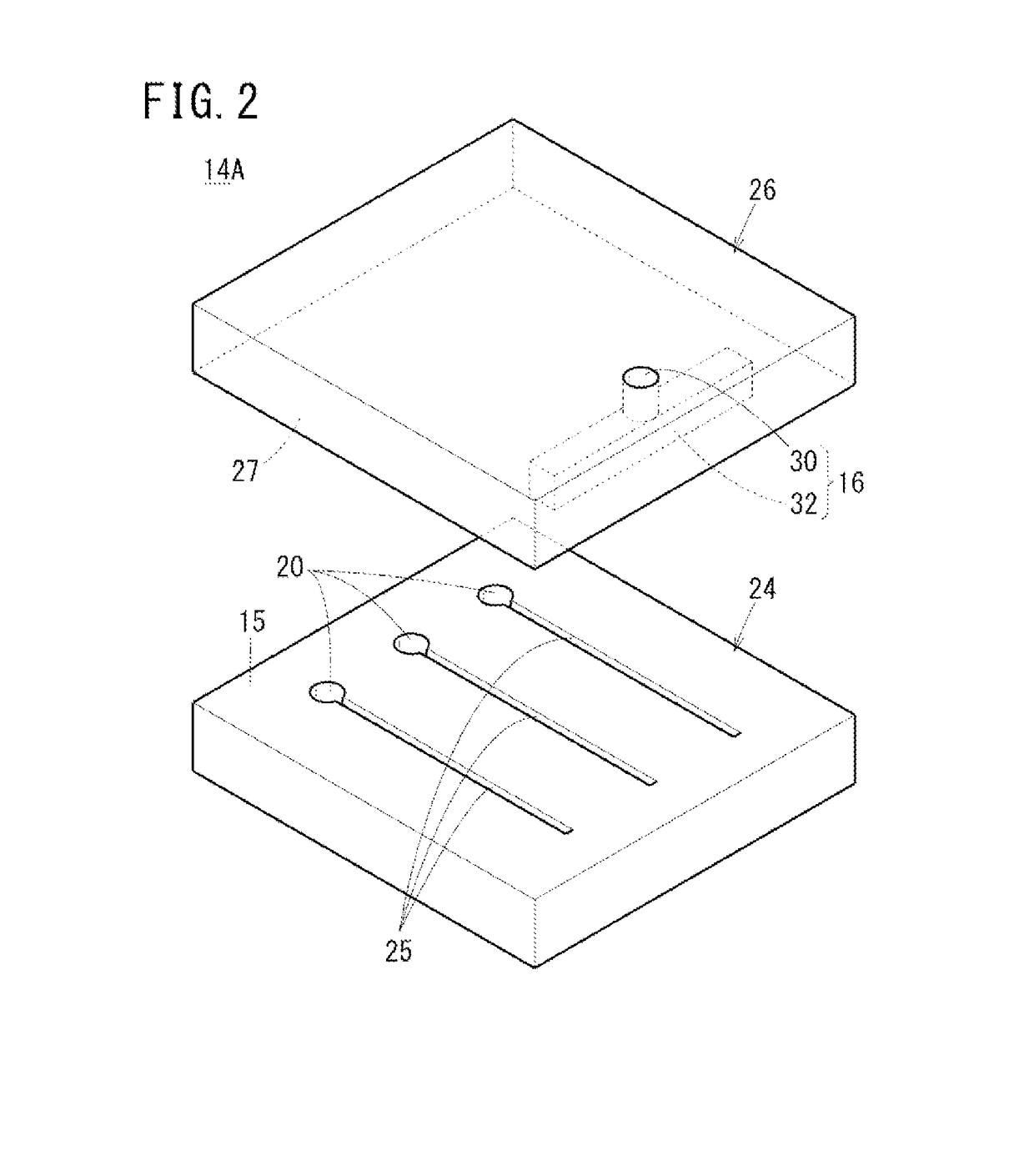

[0057]A preferred embodiment of a throttle unit and a static pressure bearing device having the throttle unit, and a method of manufacturing a grooved block according to the present invention will be described below with reference to the accompanying drawings.

[0058]A static pressure bearing device 10A shown in FIG. 1 is equipped with a bearing unit 12, and a throttle unit 14A attached to the bearing unit 12. Though the detailed structure is not shown, the bearing unit 12 is equipped with a structure with a linear motion axis, in which a guide as a fixed portion and a slide as a movable portion are provided. A plurality of static pressure pockets are formed on a bearing surface of the slide or the guide. When a working fluid such as air is supplied to the static pressure pockets, the slide floats above the guide by the static pressure of the working fluid and can move along the guide in a non-contact manner. The bearing unit 12 may have a structure with a rotary axis.

[0059]The thrott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com