Aluminum alloy sheet

a technology of aluminum alloy and rolled sheets, applied in the field of aluminum alloy sheets, can solve the problems of not being practical, significantly different production methods according to the techniques, and little use of rolled sheets of 7xxx-series aluminum alloy in practice, so as to improve shock absorption, maintain strength, and improve shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

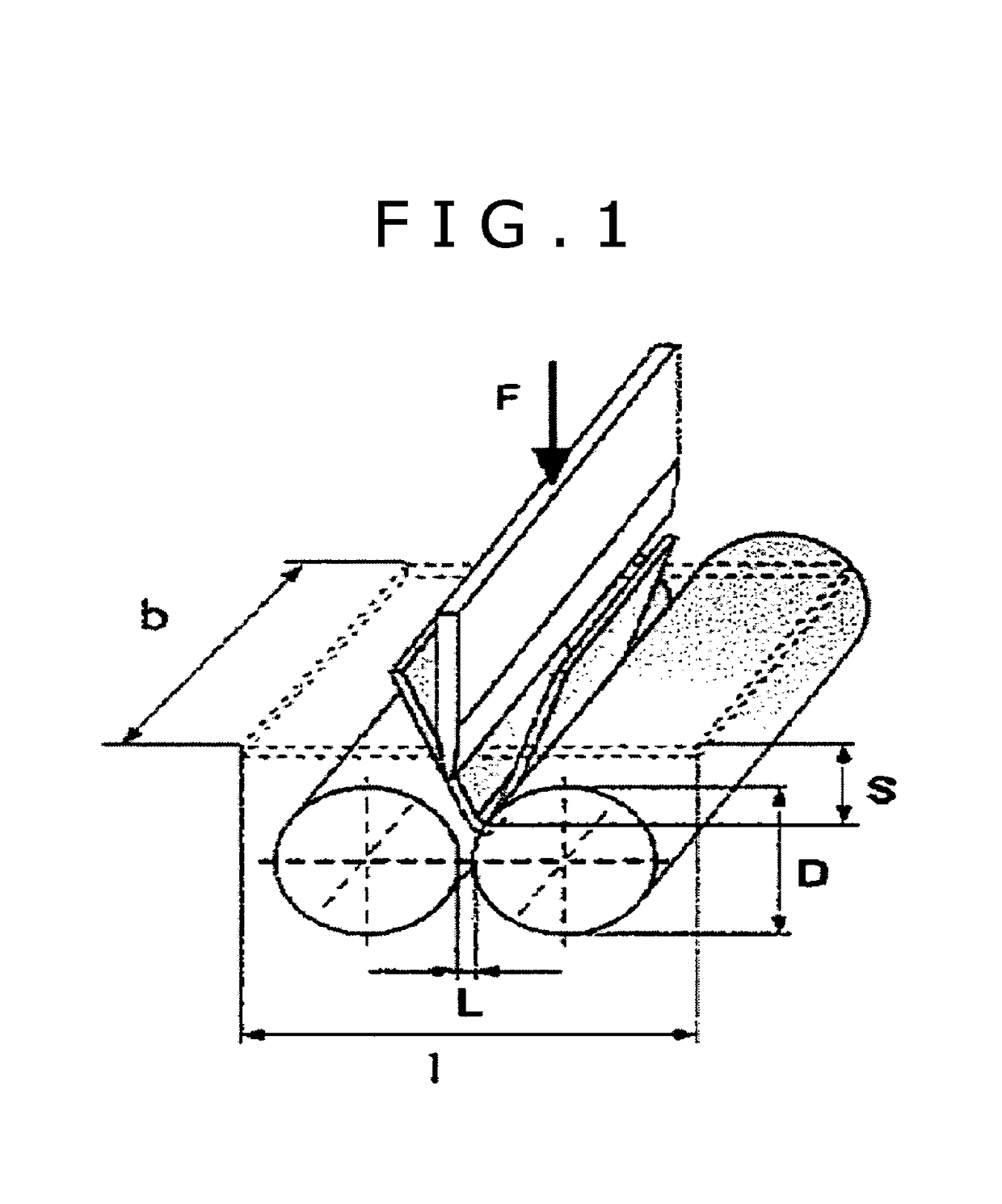

Method used

Image

Examples

examples

[0120]Cold-rolled sheets were produced from 7xxx-series aluminum alloys having the chemical compositions given in Table 1, under different conditions as given in Table 2 so as to have different textures. The cold-rolled sheets were evaluated on mechanical properties such as strength; and on shock absorption (crushing properties), where the shock absorption is evaluated by VDA bend tests. The results of them are presented in Table 3.

[0121]The cold-rolled sheet textures were controlled mainly by varying soaking conditions and solution treatment conditions as given in Table 2. Specifically, in common to each sample, 7xxx-series molten aluminum alloys having the chemical compositions given in Table 1 were subjected to direct chill casting (DC casting) to give ingots, the ingots were subjected to soaking and hot rolling under the soaking conditions and at the hot rolling start temperatures given in Table 2 and yielded hot-rolled sheets having thicknesses of 3 mm to 25 mm. These hot-rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com