Pocket wax dispenser

a dispenser and pocket wax technology, applied in the field of pocket wax dispensers, can solve the problems of difficult dispense of small quantities when needed, and achieve the effect of avoiding drawbacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

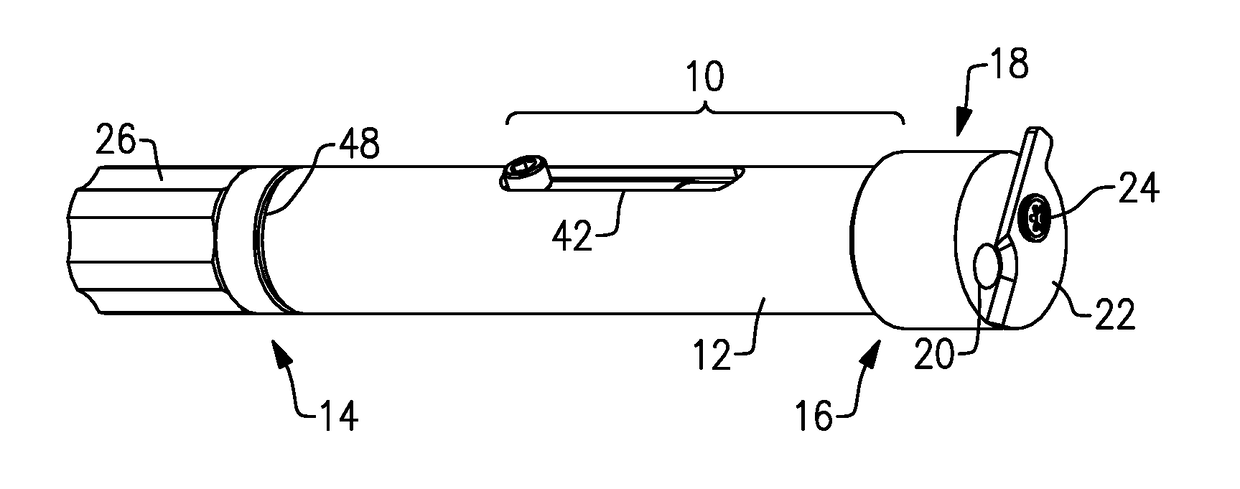

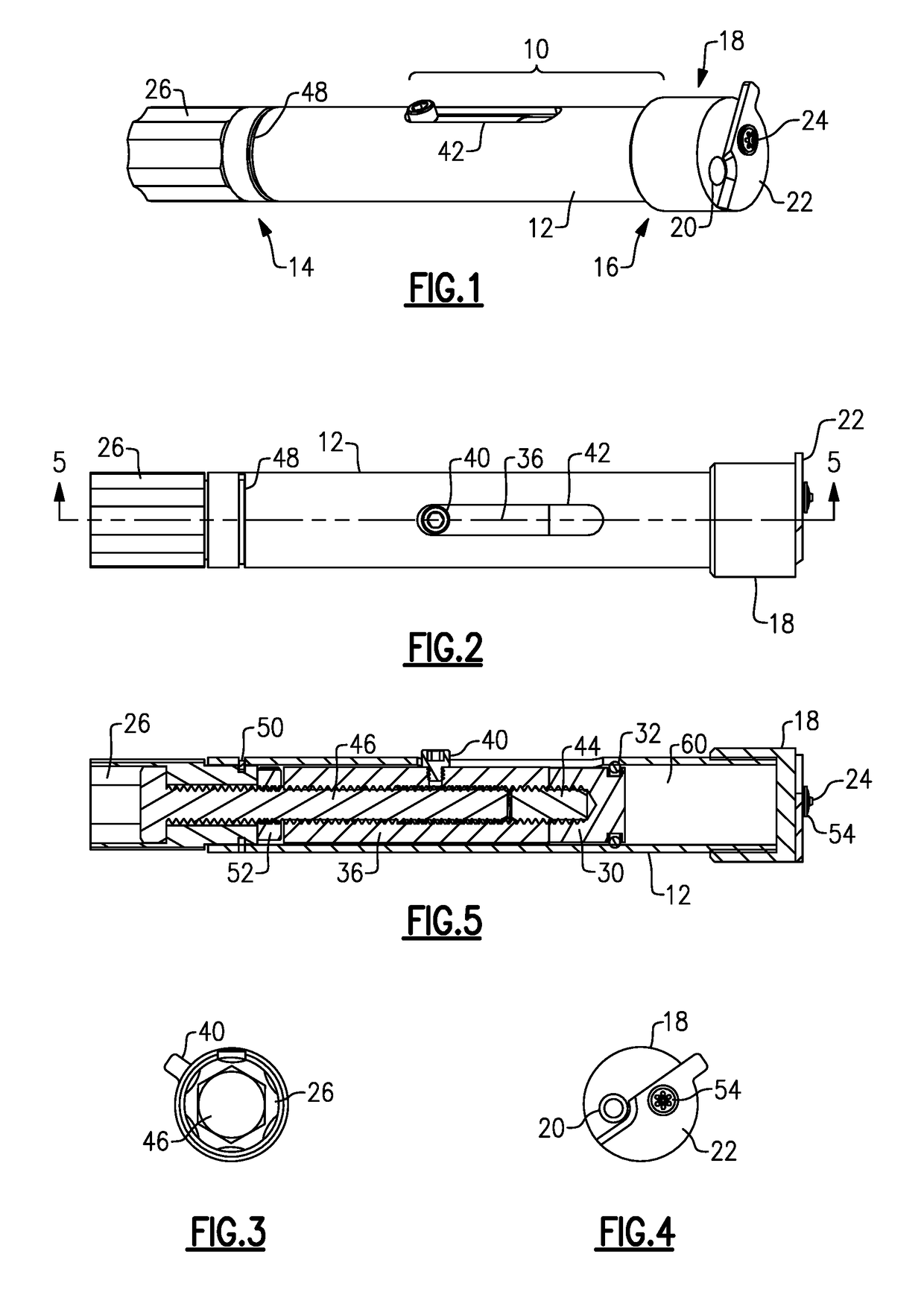

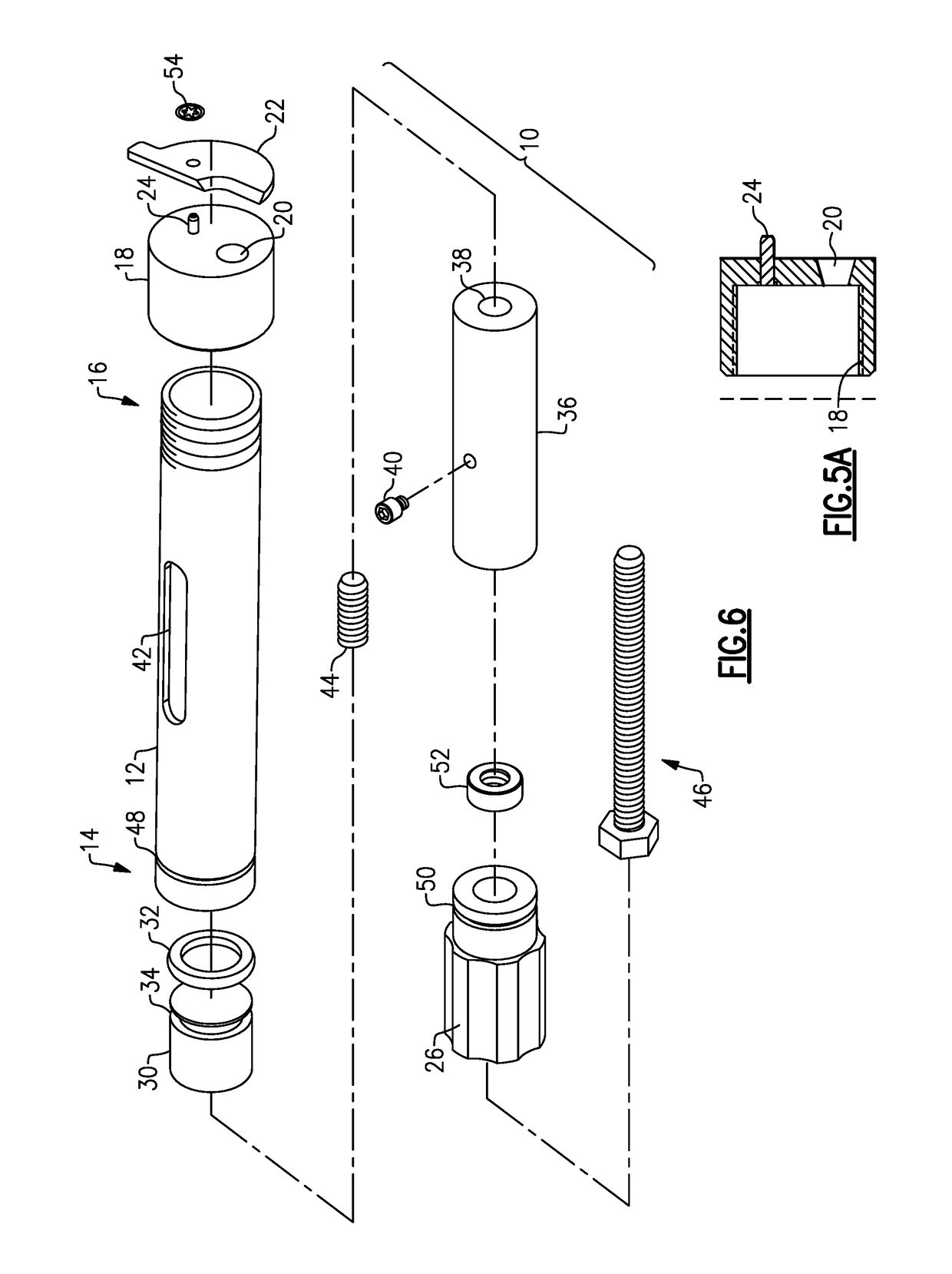

[0017]With reference to the Drawing, and initially to FIGS. 1 to 6, a wax dispenser 10 has a generally tubular casing 12 which may be formed of metal or a suitable tough plastic resin, and has a back end or proximal end 14 and a front end or distal end 16. An end cap 18 screws or snaps onto the distal end 16. The cap 18, on one side of the central axis of the dispenser has a round dispensing port 20 out from which the wax can be extruded, and which has a generally conic or frustoconic shape in this embodiment (See FIG. 5A). A cutter or generally flat metal cutting knife 22 is pivotally mounted on a pivot pin 24 that projects axially out from the end cap 18, at the opposite side of the axis, so that a cutting edge of the cutter 22 can slice the extruded quantity of wax that comes out of the dispensing port 20. The cutter also serves to cover the dispensing port 20 after the wax has been dispensed.

[0018]A knob 26 positioned at the proximal end 14 of the casing can be rotated to extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com