Method for pile-driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

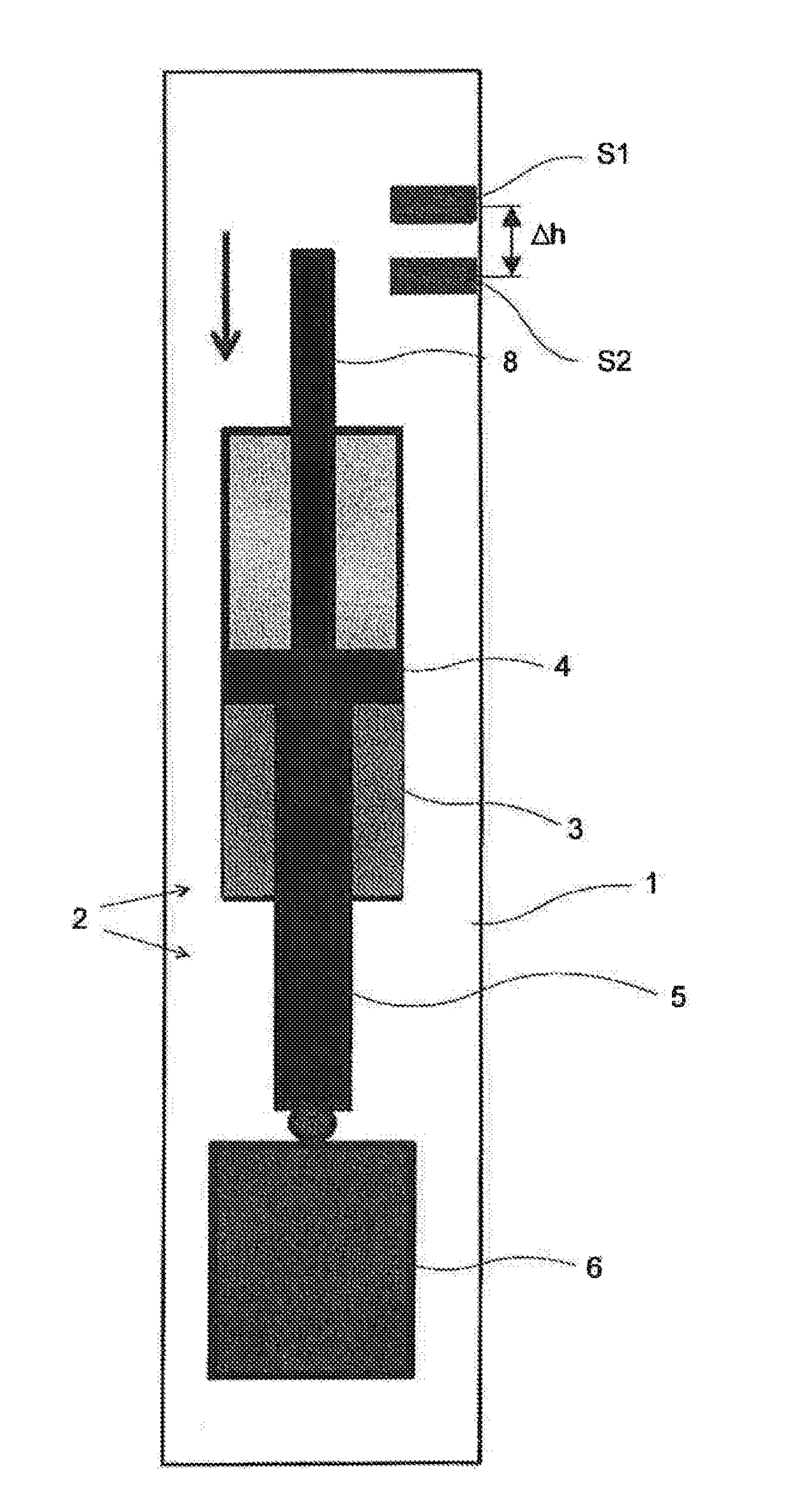

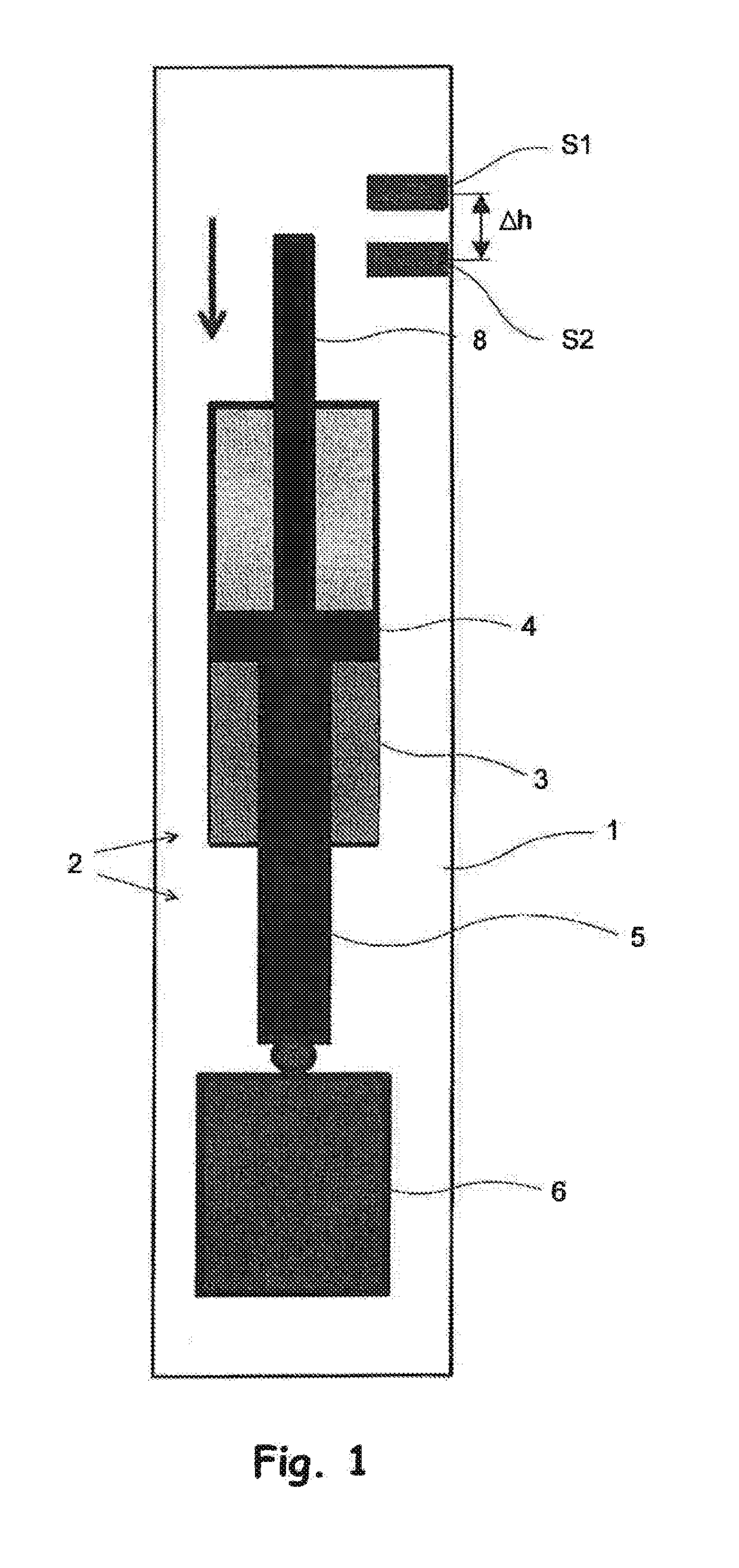

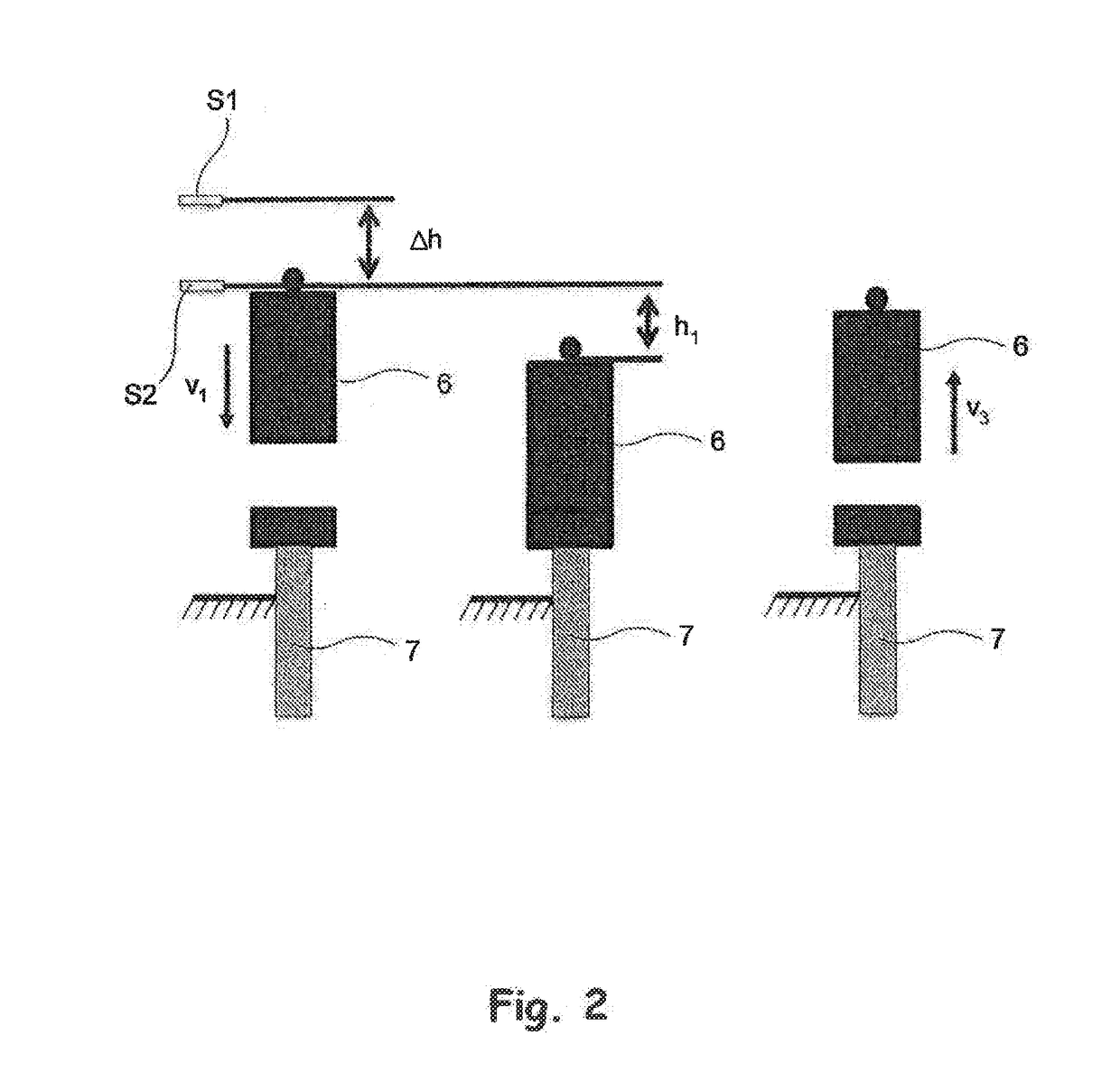

[0012]FIG. 1 shows the operating principle of a mechanism 2 for moving a block 6 movable inside a hydraulically operated hammer ram 1 of a pile-driving machine. It comprises a hydraulic cylinder 3 extending in the longitudinal (vertical) direction of the hammer ram 1, and a piston 4 movable therein. A piston rod 5 extends from the piston 4 to the block 6 underneath the cylinder. Thus, when the piston 4 is moved back and forth inside the hydraulic cylinder 3 by pressurized medium supplied to different sides of the piston 4 in an alternating manner, the block 6 underneath the hydraulic cylinder 3 moves a corresponding distance in the vertical direction of the hammer ram 1. This reciprocating motion is utilized in driving a pile 7 by placing the hammer ram 1 on the pile 7 in such a way that when the block 6 comes to the lower position, it hits the top end of the pile 7. Normally, a cushioning is placed between the end of the pile 7 and the block 6, for suitably damping the impact cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com