Lateral drilling method

a drilling method and lateral drilling technology, applied in the direction of directional drilling, wellbore/well accessories, sealing/packing, etc., can solve the problems of prior art tools, difficulty in advancing the bit, and creating additional challenges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

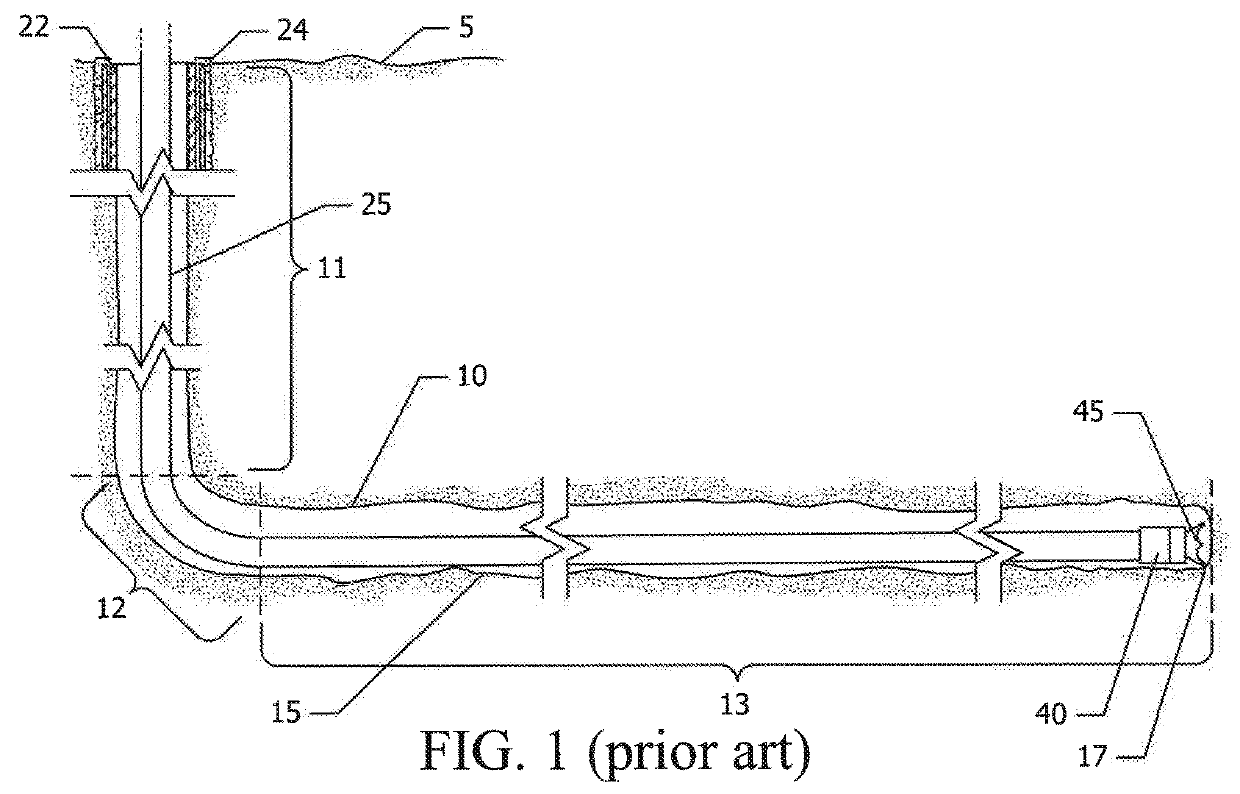

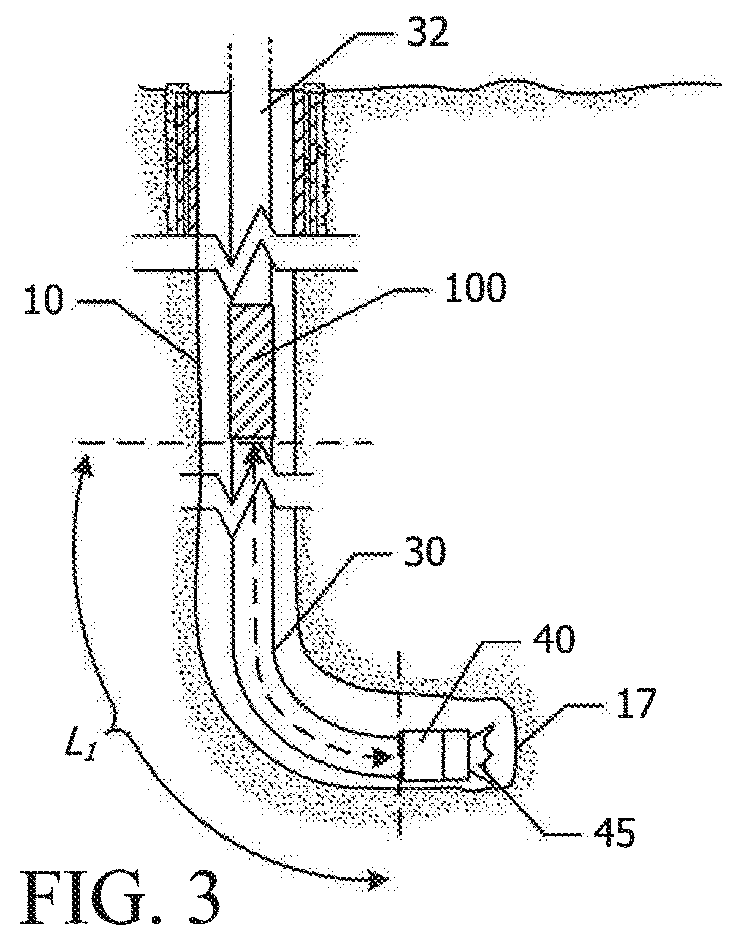

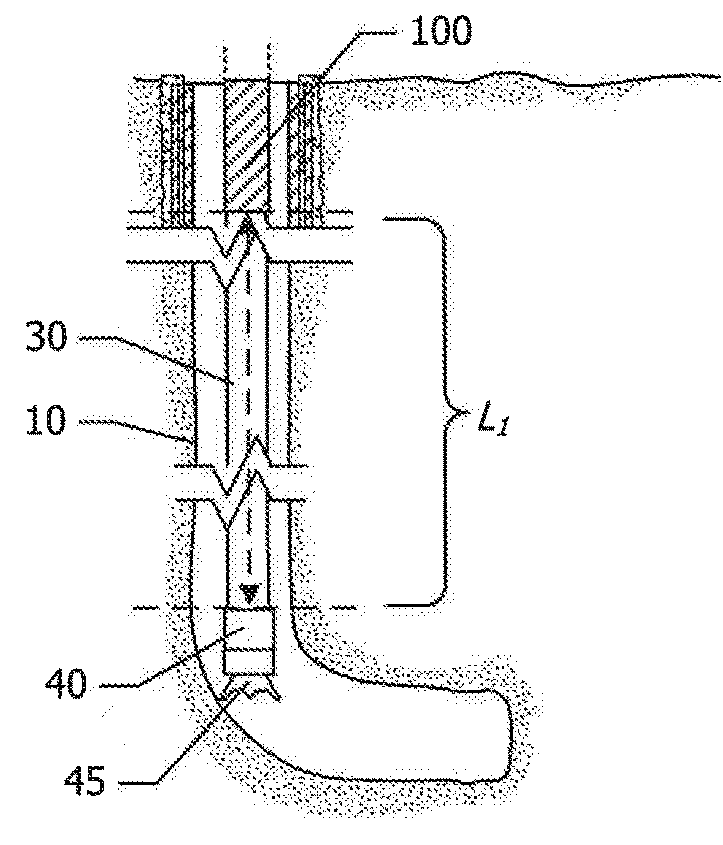

[0021]The present disclosure is directed to drilling horizontal or lateral wellbores. A prior art directional drilling string assembly 25 in use in a horizontal or lateral wellbore 10 is illustrated in FIG. 1. The wellbore 10 includes a substantially vertical section 11, a build section 12, and a lateral section 13, which in this example is substantially horizontal but may be somewhat inclined. The build section 12 generally indicated in FIG. 1 denotes individual build and tangential portions that transition the wellbore 10 from the substantially vertical section 11 to the lateral section 13. It will be appreciated by those skilled in the art that the accompanying drawings are not drawn to scale in the interest of clarity; a build section 12, for example, may have portions with slower or faster build rates than illustrated here. Further, the drawings represent a cross-sectional view of a wellbore 10, with a single build section 12 providing a transition from the substantially vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com