Method for erecting a concrete structure and climbing formwork

a concrete structure and climbing technology, applied in the field of concrete structure erection, can solve the problems of cumbersome attachment of temporary supports to the sub-frames supporting the main frame, and achieve the effect of improving the stability and stability of the structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

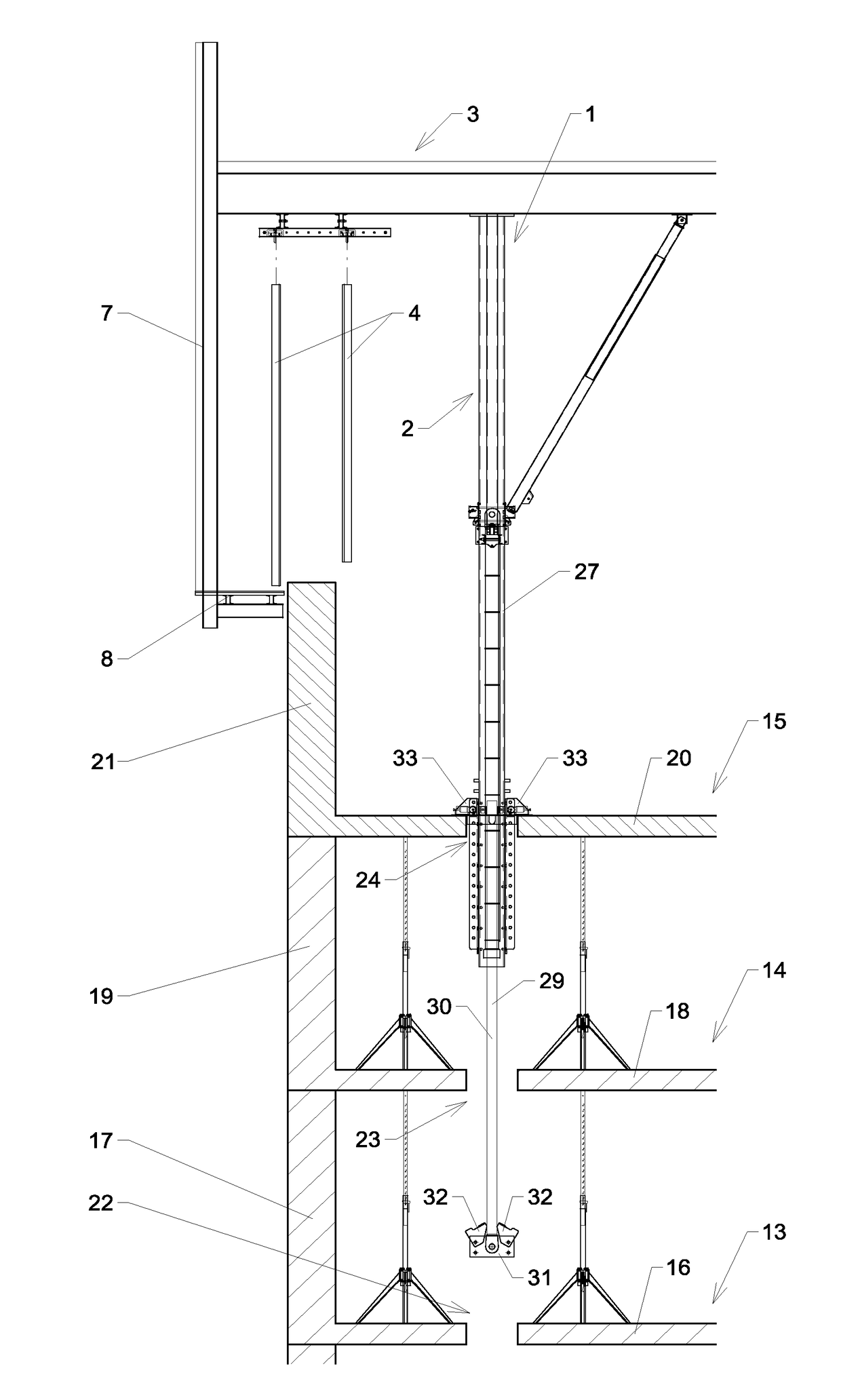

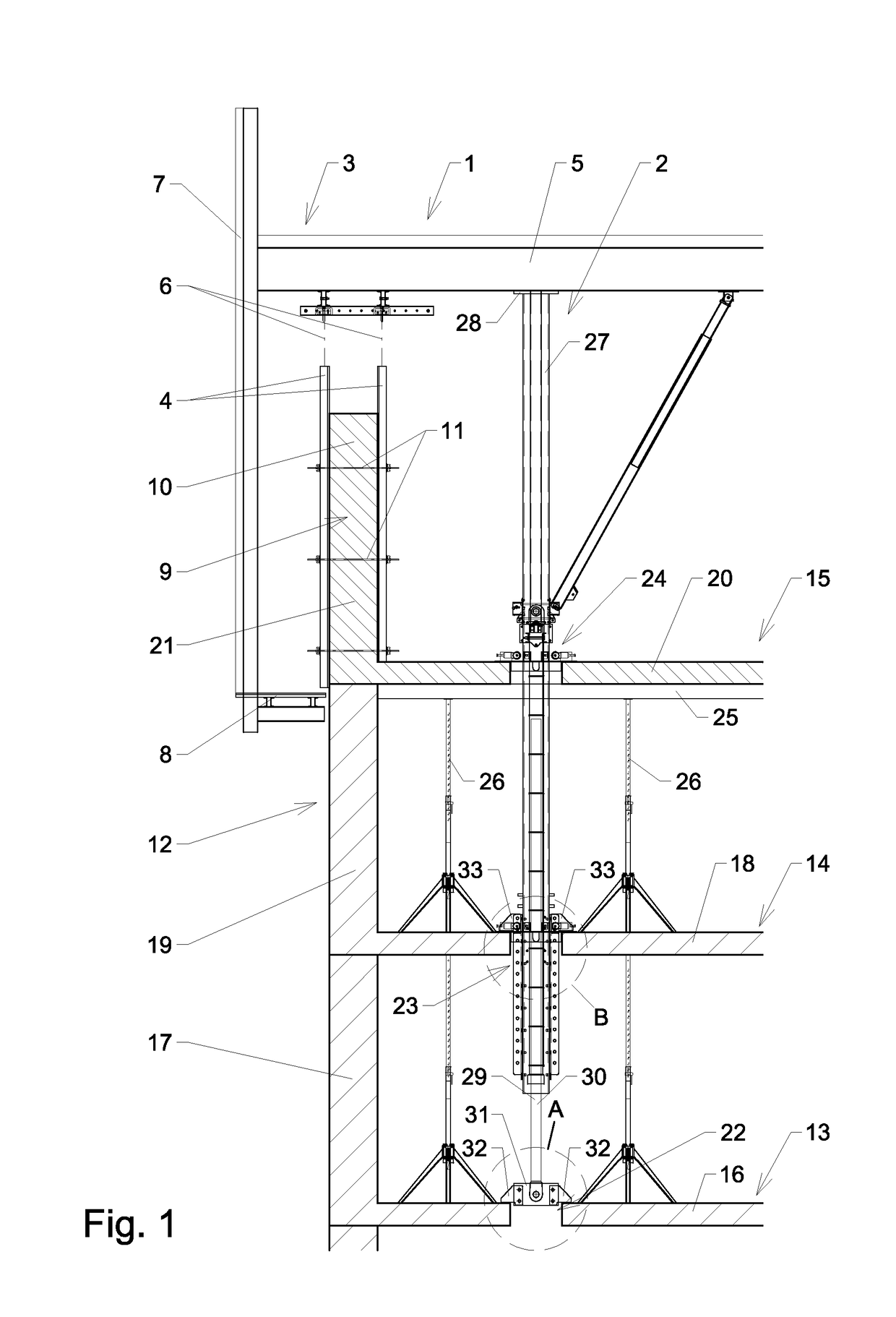

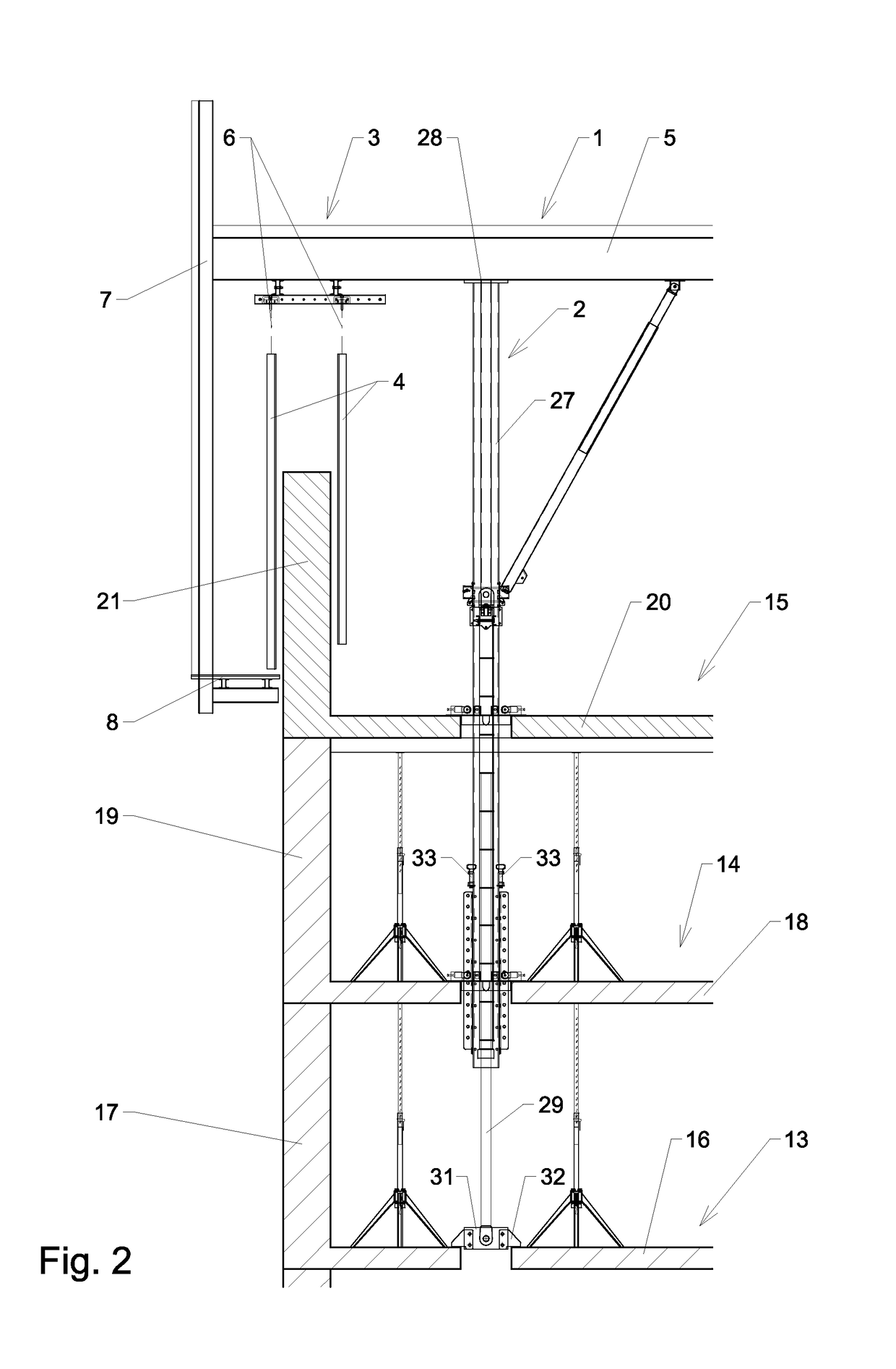

[0071]Referring to FIGS. 1 to 5 of the drawings, a first embodiment of the disclosure relates to a climbing formwork 1 with a (generally vertically extending) support column 2, a frame 3 and formworks 4. In the shown embodiment, frame 3 has a cross-beam 5 from which the formworks (for example sheathings) 4 are suspended (as illustrated by lines 6 in FIG. 1 and FIG. 2). In this embodiment, a single leg support column 2 is used. Thus, the support column 2 is not rigidly connected to another support column 2 by means other than the frame 3. It is apparent that frame 3 may comprise a number of other known frame components, such as a vertical frame member 7 carrying a working platform 8. As is well known in the prior art, the formworks 4 delimit a cavity 9 for receiving concrete 10 therebetween. Furthermore, anchors 11 may be arranged for holding the formworks 4 together during casting. In the shown example, the climbing formwork 1 is used for constructing a concrete structure 12, for ex...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap