Optical waveguide

a waveguide and optical wave technology, applied in the field of optical waveguides, to achieve the effect of preventing the attenuation of light propagating in the core, enhancing crosstalk without high costs, and reducing the cost of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

##ventive example 1

Inventive Example 1

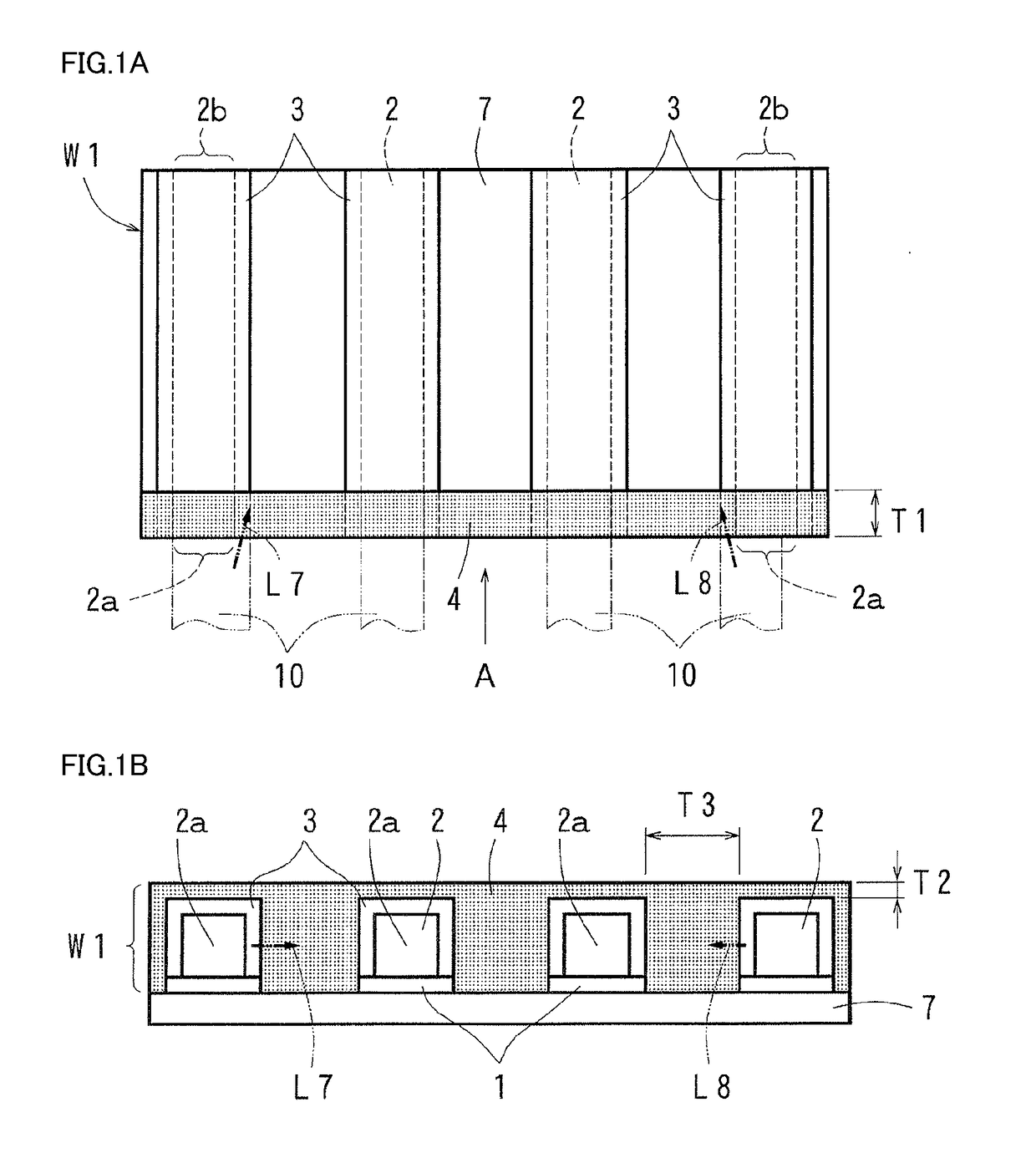

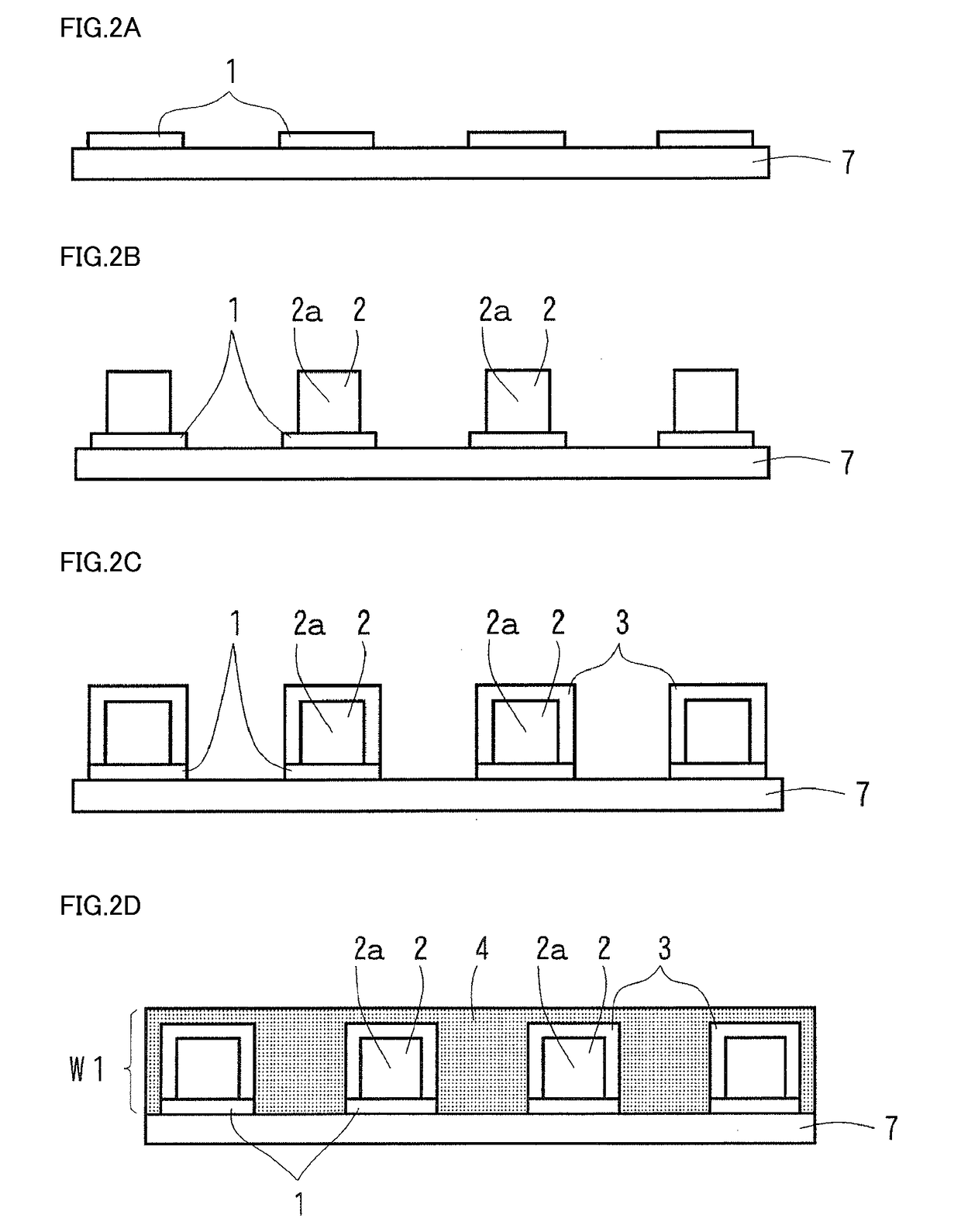

[0109]Using the aforementioned materials, the optical waveguide (having a length of 50 mm) of the first embodiment shown in FIGS. 1A and 1B was produced on a surface of a substrate made of a resin. The under claddings had the following dimensions: a thickness of 40 μm; a width of 100 μm; and a gap width of 150 μm between adjacent ones of the under claddings. The cores had the following dimensions: a thickness of 40 μm; a width of 40 μm; and a spacing of 250 μm therebetween. Portions of the over claddings which covered the side surfaces of the cores had a thickness of 30 μm, and portions of the over claddings which covered the top surfaces of the cores had a thickness of 30 μm. The light absorbing part had the following dimensions: a depth of 10 mm as measured from a first end surface of the optical waveguide; a width of 150 μm in portions present between adjacent ones of the over claddings; and a thickness of 15 μm as measured from the top surfaces of the over cla...

##ventive example 2

Inventive Example 2

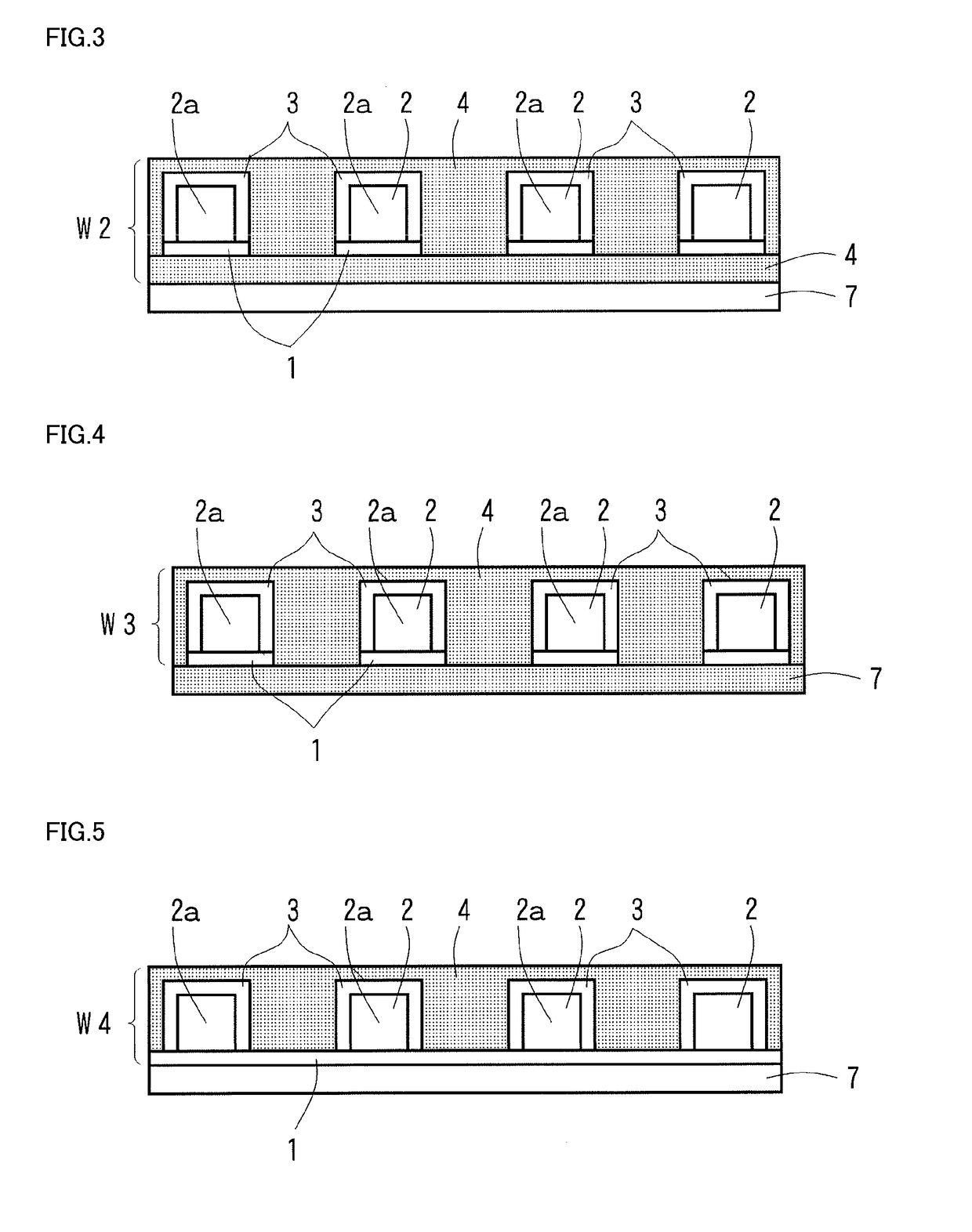

[0110]Using the aforementioned materials, the optical waveguide (having a length of 50 mm) of the second embodiment shown in FIG. 3 was produced on a surface of a substrate made of a resin. The layer of the light absorbing part provided between the under claddings and the substrate had a thickness of 20 μm. The remaining parts had the same dimensions as those in Inventive Example 1.

##ventive example 3

Inventive Example 3

[0111]Using the aforementioned materials, the optical waveguide (having a length of 50 mm) of the fourth embodiment shown in FIG. 5 was produced on a surface of a substrate made of a resin. The components including the cores had the same dimensions as those in Inventive Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com