Method for forming multijunction metamorphic solar cells for space applications

a solar cell and multi-junction technology, applied in the field of solar cells and the fabrication of solar cells, can solve the problems of tens of more complex requirements for proper specification and manufacture, and achieve the effect of increasing the efficiency of photoconversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

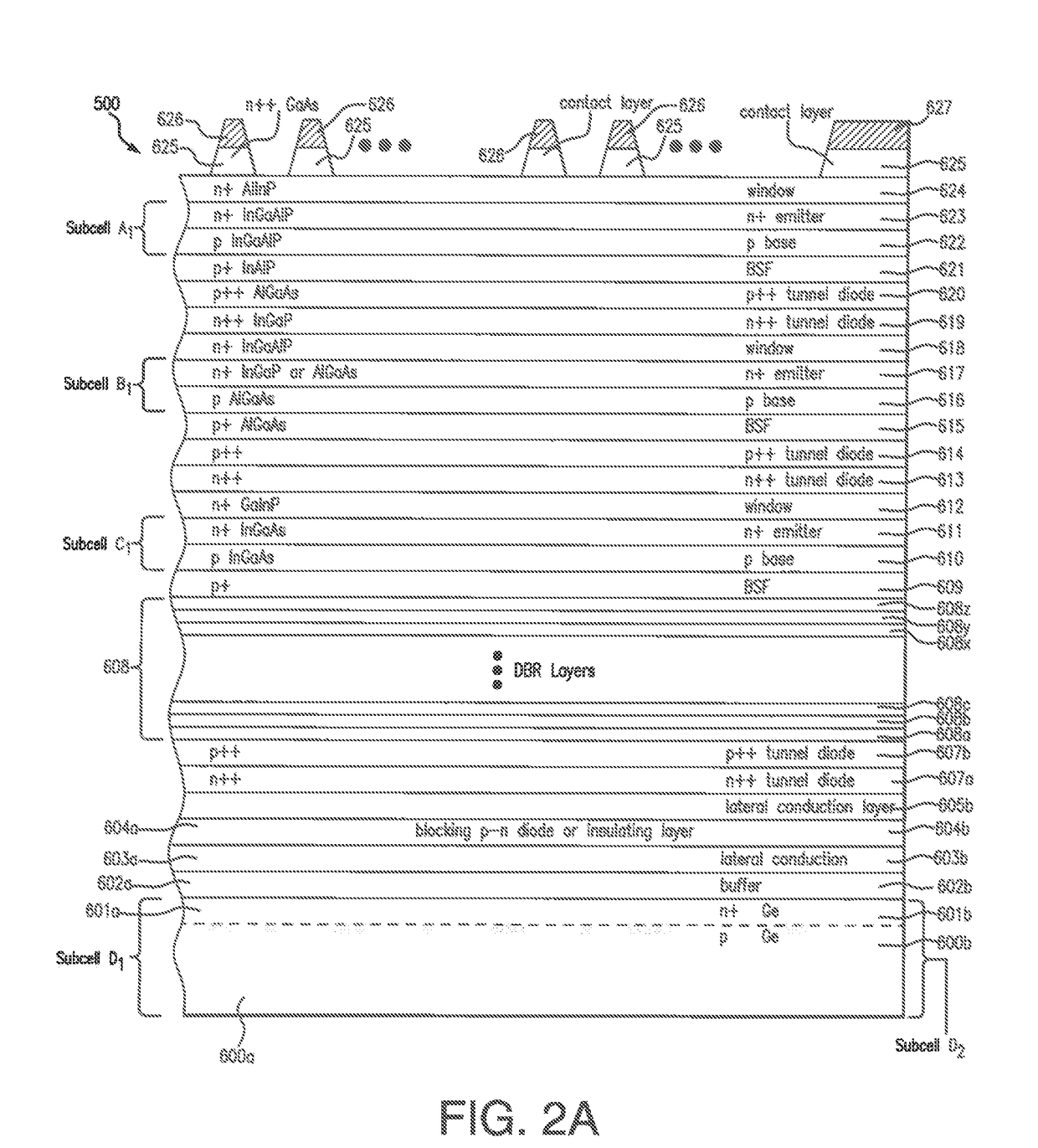

[0159]Turning to the fabrication of the multijunction solar cell assembly of the present disclosure, and in particular a five-junction solar cell assembly, FIG. 2A is a cross-sectional view of a semiconductor body 500 after several stages of fabrication including the growth of certain semiconductor layers on the growth substrate, and formation of grids and contacts on the contact layer of the top side (i.e., the light-facing side) of the semiconductor body.

[0160]As shown in the illustrated example of FIG. 2A, the bottom subcell (which we refer to initially as subcell D) includes a substrate 600 formed of p-type germanium (“Ge”) in some embodiments, which also serves as a base layer of the subcell (i.e., the p-polarity layer of a “base-emitter” photovoltaic junction formed by adjacent layers of opposite conductivity type).

[0161]In some embodiments, the bottom subcell D is germanium, while in other embodiments the fourth subcell is InGaAs, GaAsSb, InAsP, InAlAs, or SiGeSn, InGaAsN, In...

second embodiment

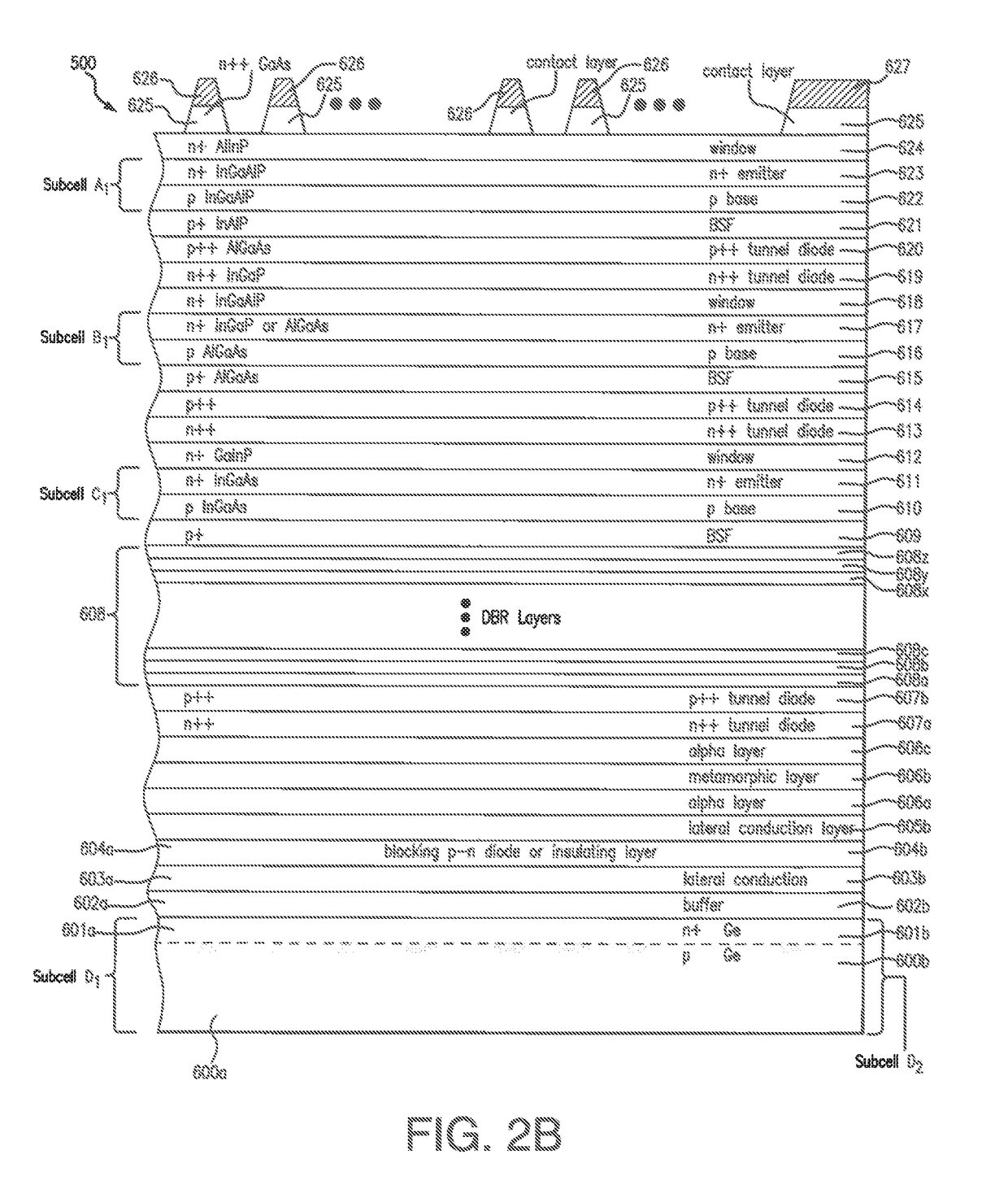

[0180]FIG. 2B is a cross-sectional view of a semiconductor body including a four solar subcells including two lattice mismatched subcells with a metamorphic layer between them, after several stages of fabrication including the growth of certain semiconductor layers on the growth substrate up to the contact layer, according to the present disclosure.

[0181]As shown in the previously illustrated example of FIG. 2A, the bottom subcell (which we refer to initially as subcell D) includes a substrate 600 formed of p-type germanium (“Ge”) in some embodiments, which also serves as a base layer, and since the layers 601 through 605 are substantially the same as described in connection with FIG. 2A, they will not be described in detail here for brevity.

[0182]In the embodiment of FIG. 2B, a first alpha layer 606a, composed of n-type (Al)GaIn(As)P, is deposited over the first lateral conduction layer 605, to a thickness of between 0.25 and 1.0 micron. Such an alpha layer is intended to prevent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com