Pneumatic multi-valve device and production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

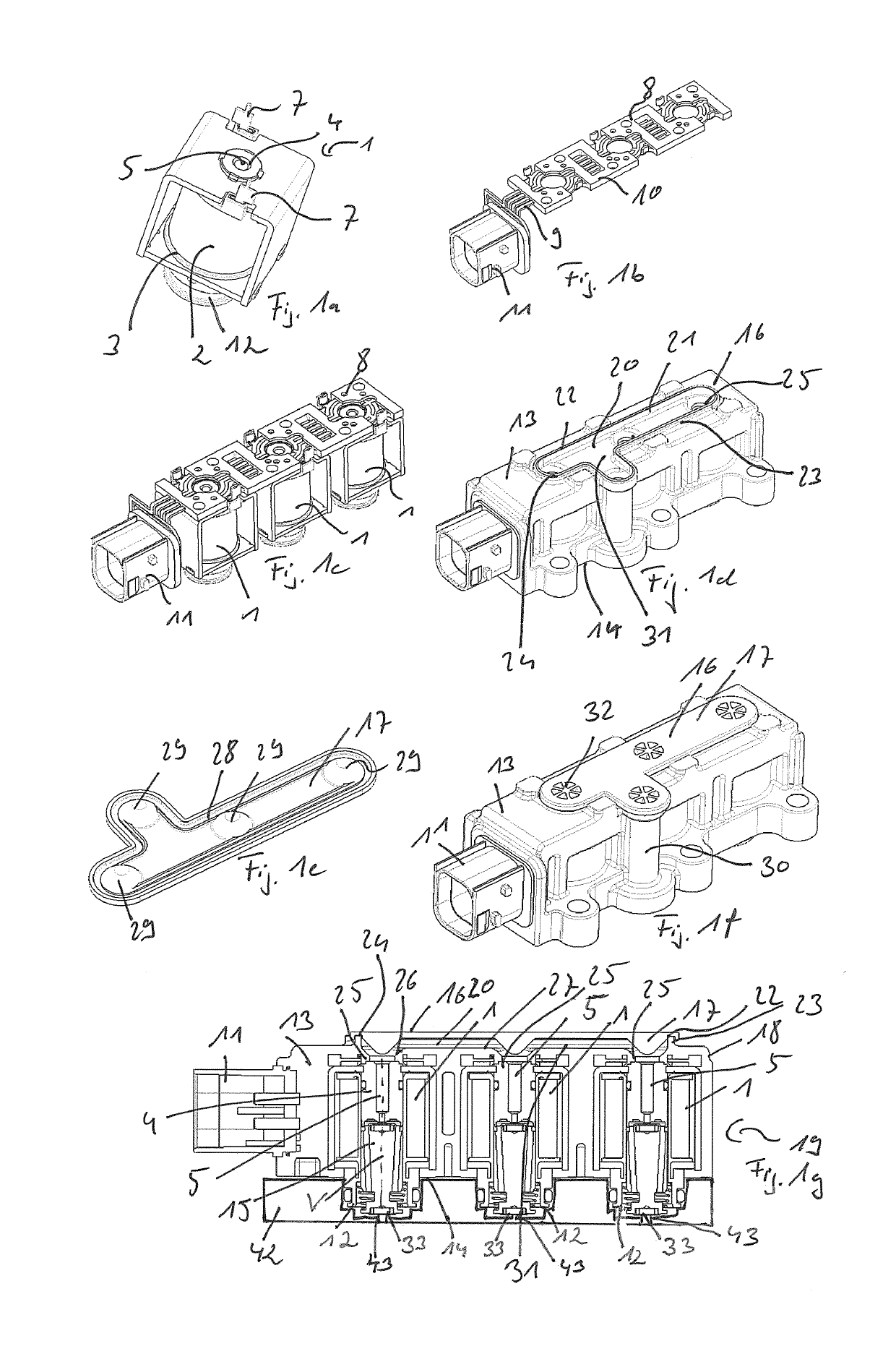

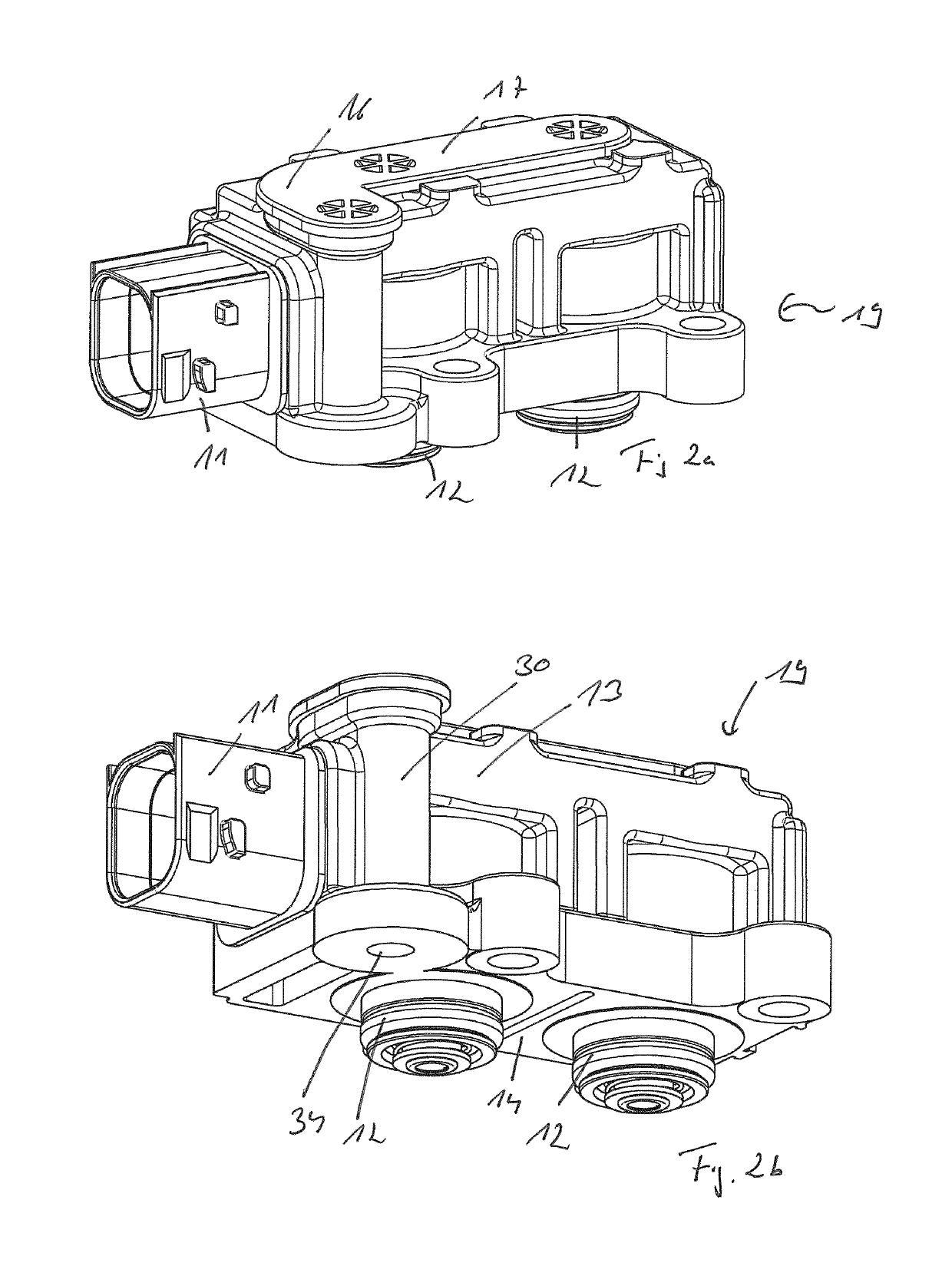

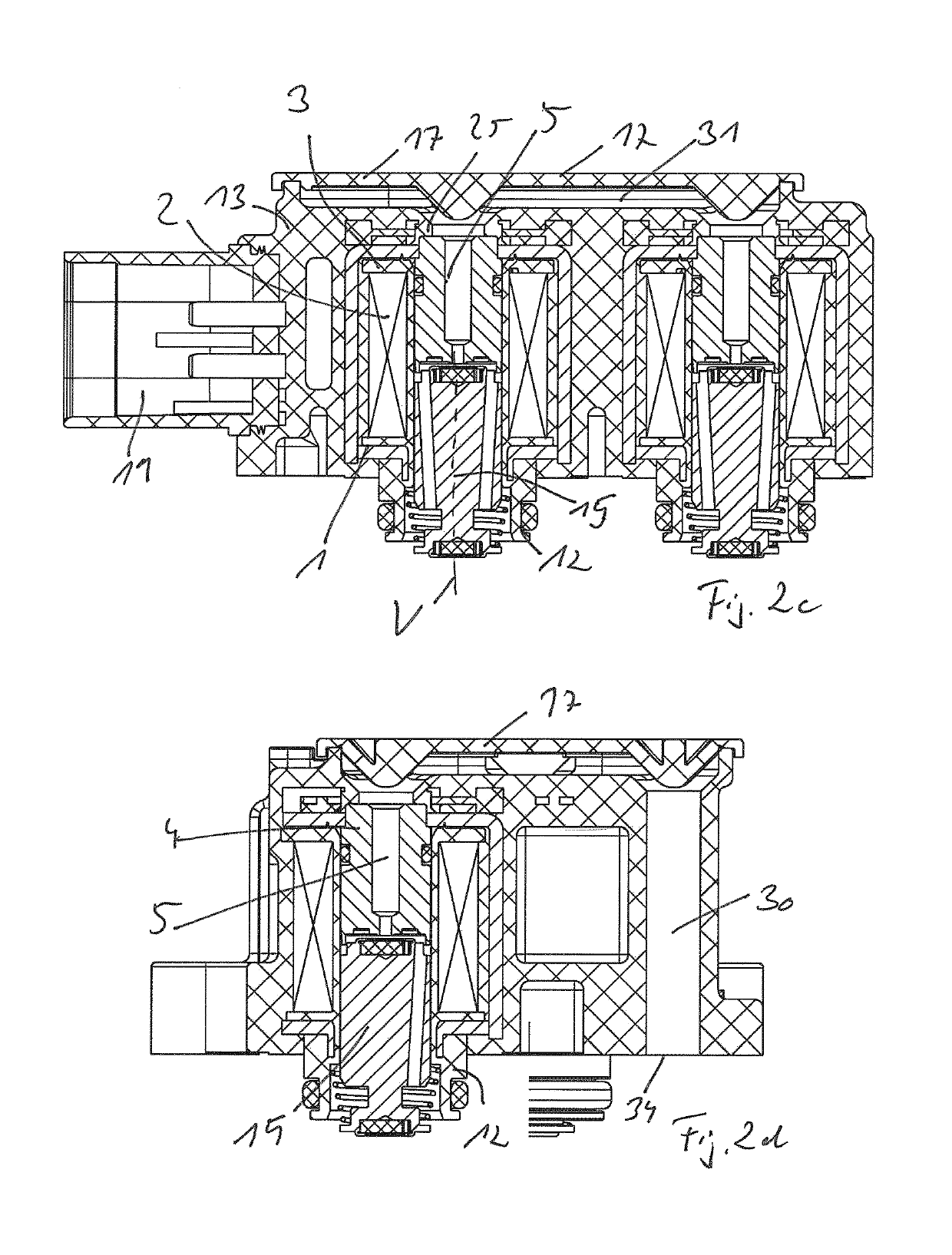

[0030]FIGS. 1a to 1e show different assembly steps and components for producing a valve device according to the invention, which is illustrated in FIG. 1f in a perspective view and which, in turn, is illustrated in a sectional view in FIG. 1g.

[0031]FIG. 1a shows a preassembled, electromagnetic valve actuator 1, of which a plurality—here for example three pieces—is provided in the finished multi-valve device (valve block) illustrated in FIGS. 1f and 1g. The electromagnetic valve actuator 1 comprises an energizable coil element 2 (electrical winding), which is arranged on a coil carrier 3, which is embodied as plastic injection molded part. A core 4 for the electromagnetic interaction with non-illustrated armature elements is located in a central passage opening (central bore) of the coil carrier 3. A central venting bore 5 is provided in the core 4. The coil elements 3 are clasped by a magnetically conducting yoke 6 for surrounding the magnetic circuit. Electrical contact elements 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com