Muzzleloader systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

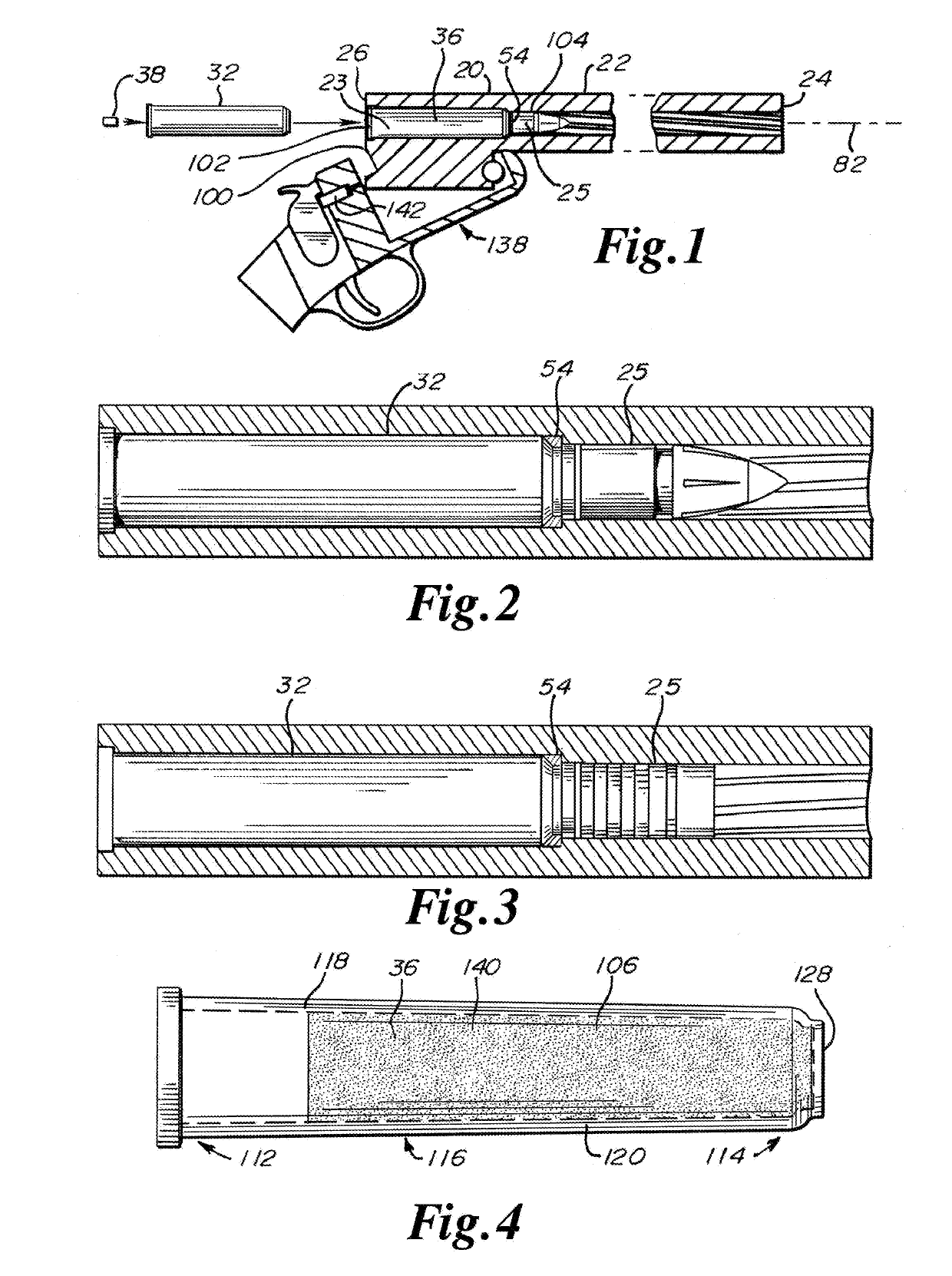

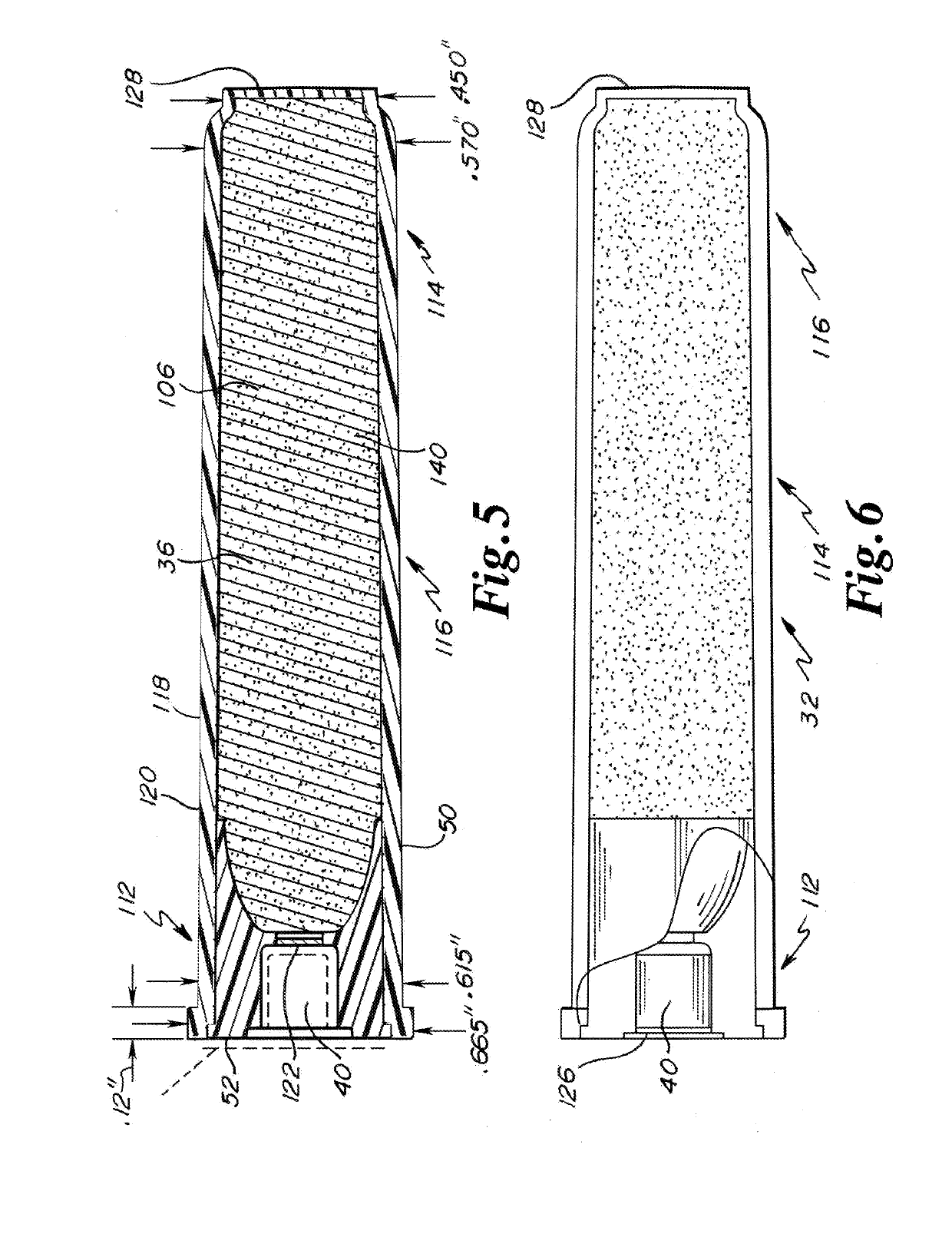

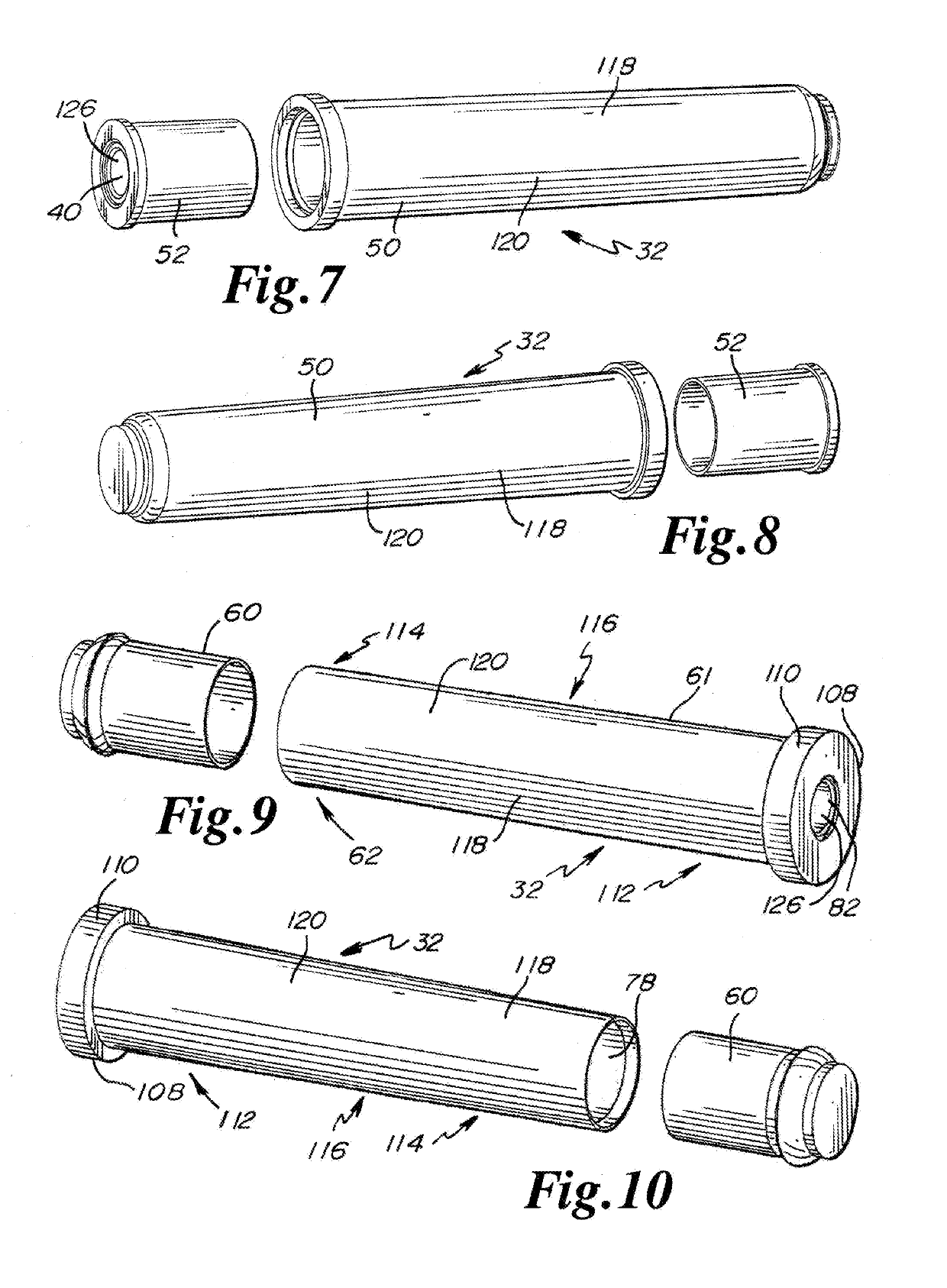

[0037]Referring to FIGS. 1 and 4-12, in embodiments, a muzzleloader system comprises muzzle loader 20, a polymer propellant vessel 32 with propellant 106 hermetically sealed therein, a projectile 25 and a primer 38. In embodiments, the muzzle loader 20 comprises a stock 134, a receiver 136 and a barrel 22, the barrel 22 having a breech end 26, a muzzle end 24, and a barrel bore 31 with a barrel axis 82. In embodiments, the muzzle loader 20 is openable exposing a breech face 100 of the barrel 22 and a propellant containment vessel chamber 36 opening at the breech face 100. In embodiments, the propellant containment vessel chamber 36 extends at least 2.5 inches inwardly from the breech face 100. In embodiments, the propellant containment vessel chamber 36 has an annular flange recess 102 at the breech face 100 extending axially inwardly at least 0.08 inches. In embodiments, the barrel 22 has a constriction portion 54 at a forward end of the propellant containment vessel chamber 36 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com