Polishing apparatus and substrate processing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(Polishing Apparatus)

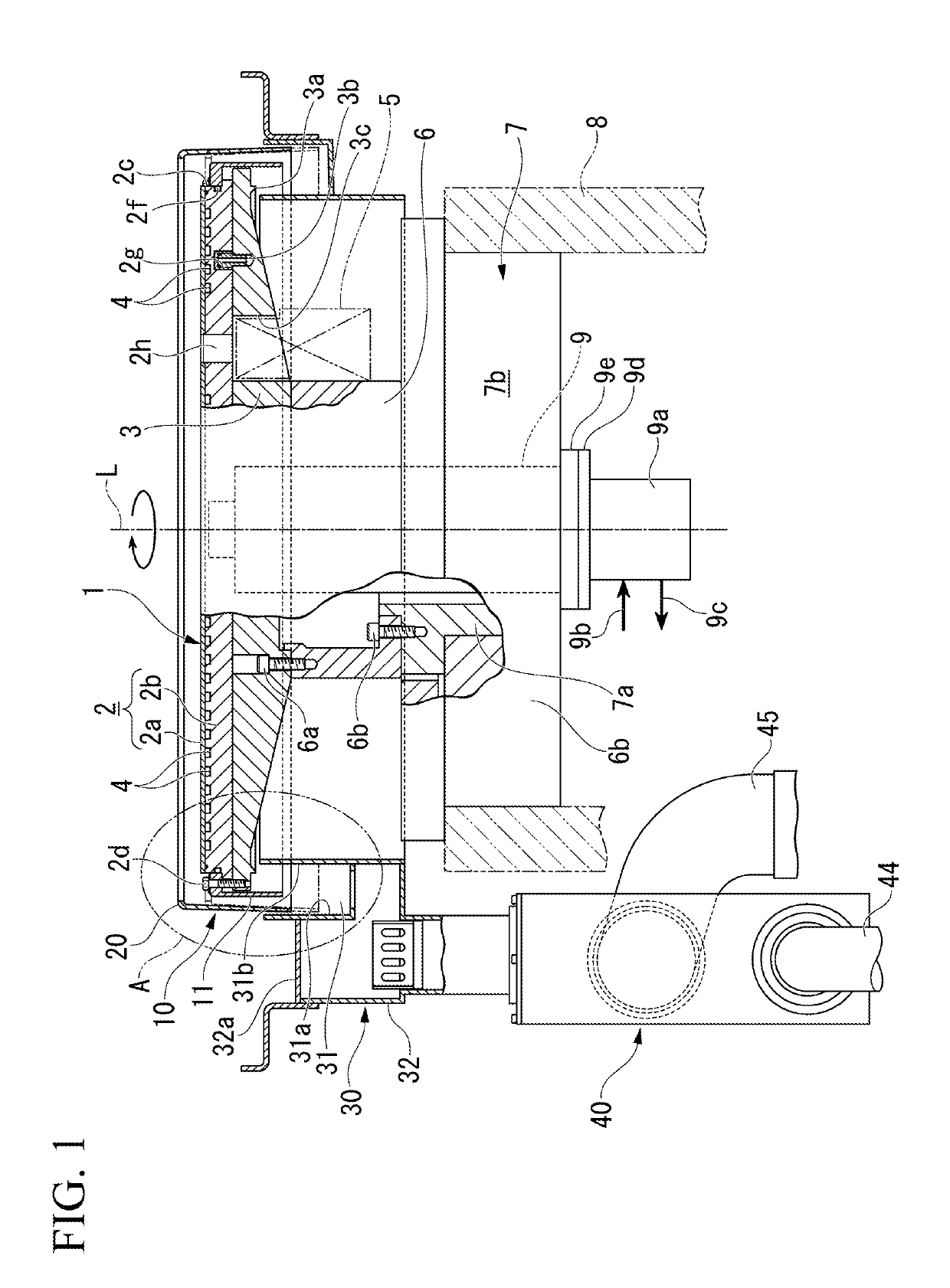

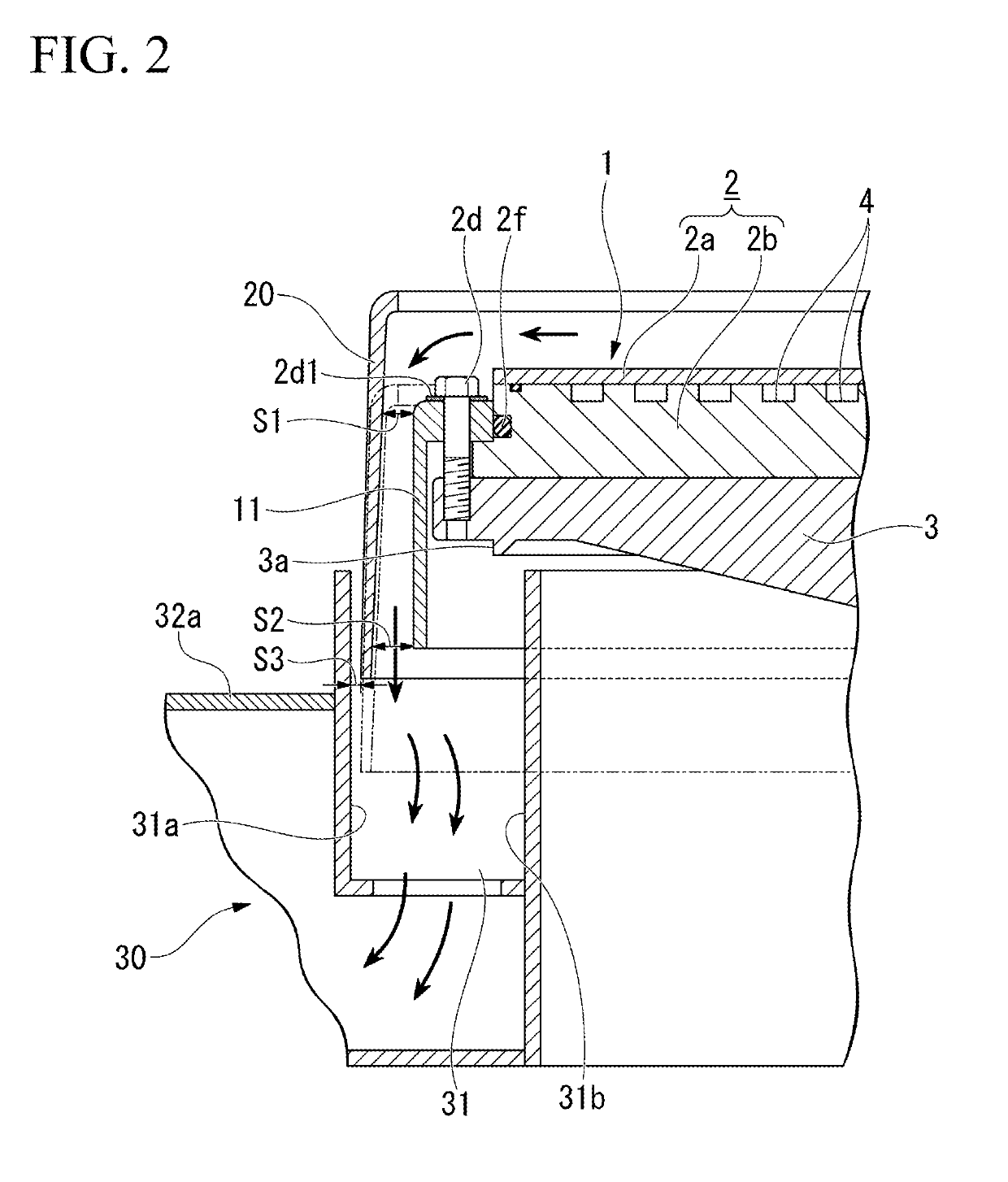

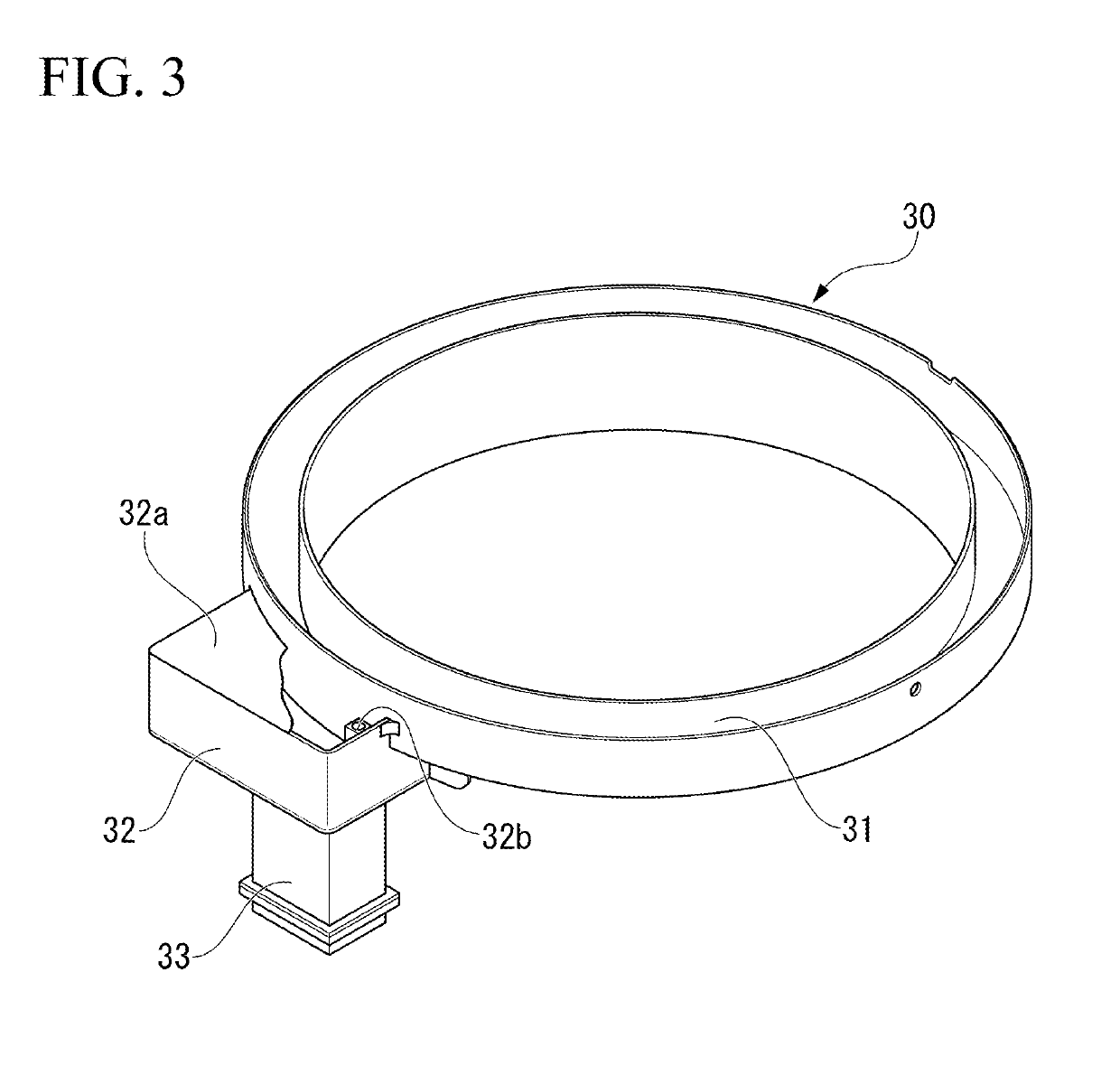

[0045]FIG. 1 is a configuration diagram of a polishing table 1 included in a polishing apparatus according to one embodiment and its peripheral structure. FIG. 2 is an enlarged view of a portion A of FIG. 1.

[0046]This polishing apparatus is incorporated in a portion of a substrate processing apparatus (described later) for processing a semiconductor substrate such as a silicon wafer. The polishing apparatus is configured to include a polishing table 1 and a top ring; however, here only the polishing table 1 is shown.

[0047]In the following description, before describing the substrate processing apparatus, the polishing table 1 of the polishing apparatus and its peripheral structure (drainage and exhaust structure 10) which is a main portion of the present invention will be described.

[0048]In the polishing table 1 shown in FIG. 1, the planar shape of the upper surface is formed in a circular shape and rotates around a central axis L passing through the center of t...

second embodiment

(Polishing Apparatus)

[0104]FIG. 6 is a configuration diagram of a polishing table 1 and its peripheral structure included in the polishing apparatus according to one embodiment. FIG. 7 is a plan view of the polishing table 1 according to one embodiment. FIG. 8 is an explanatory view showing the internal structure of the shaft 9 according to one embodiment.

[0105]In the present embodiment, different portions will be described based on the polishing apparatus of the first embodiment, and description of the same portions will be omitted.

[0106]In the heat medium flow path 4 of the present embodiment, from a side of a rotary joint 9a described later, a heat medium (such as temperature controlled water) is supplied through the shaft 9. The heat medium, as shown in FIG. 7, is supplied from a supply port 2A at a center portion of the table 2 and is discharged from the two discharge ports 2B at a center portion of the table 2. Specifically, the heat medium is supplied from the supply port 2A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com