Boat hull

a technology for boats and hulls, applied in waterborne vessels, vessel parts, marine propulsion, etc., can solve problems such as increasing wave-making resistance, stalling the forward motion of the vessel, and constant challenges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

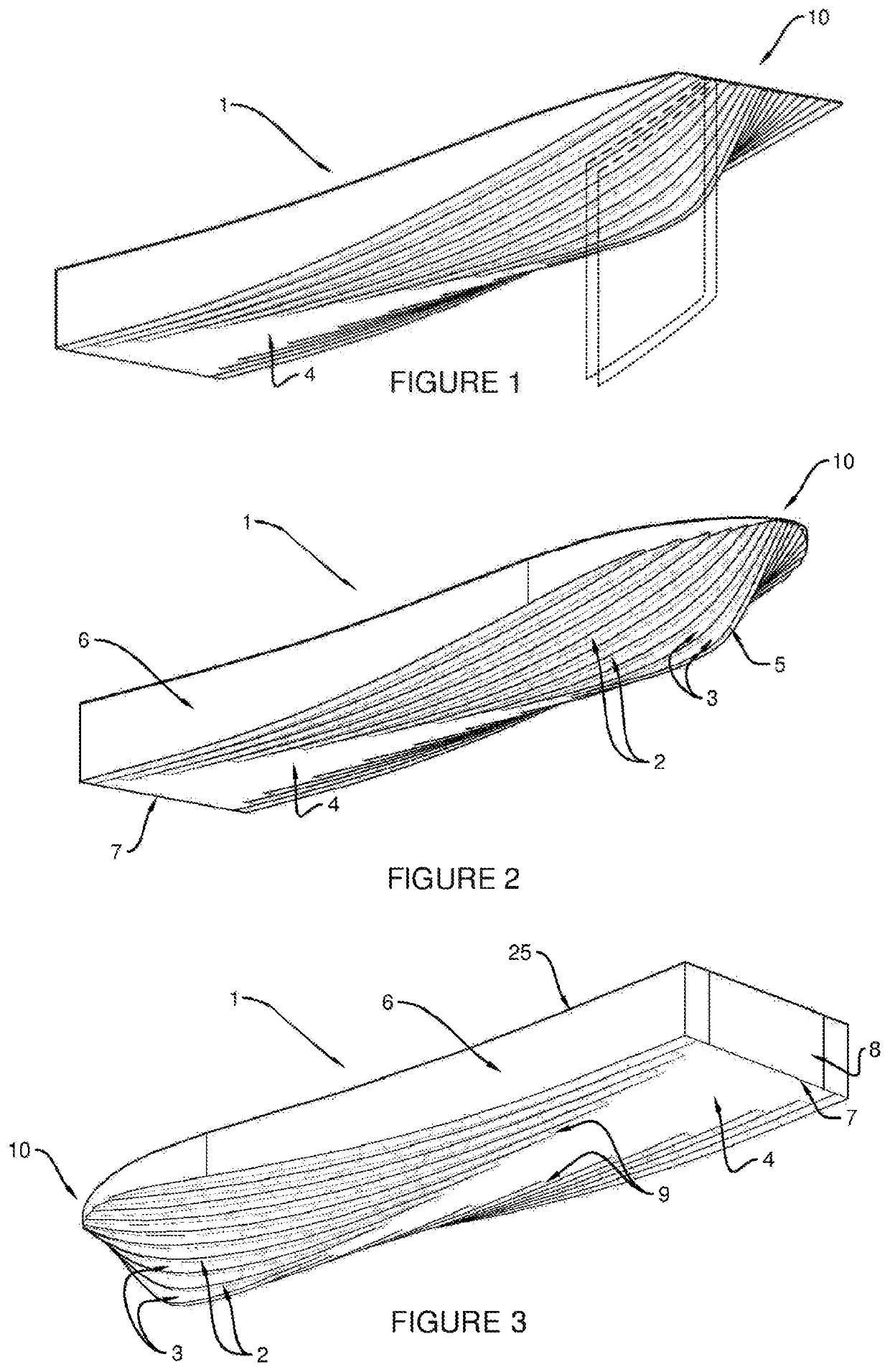

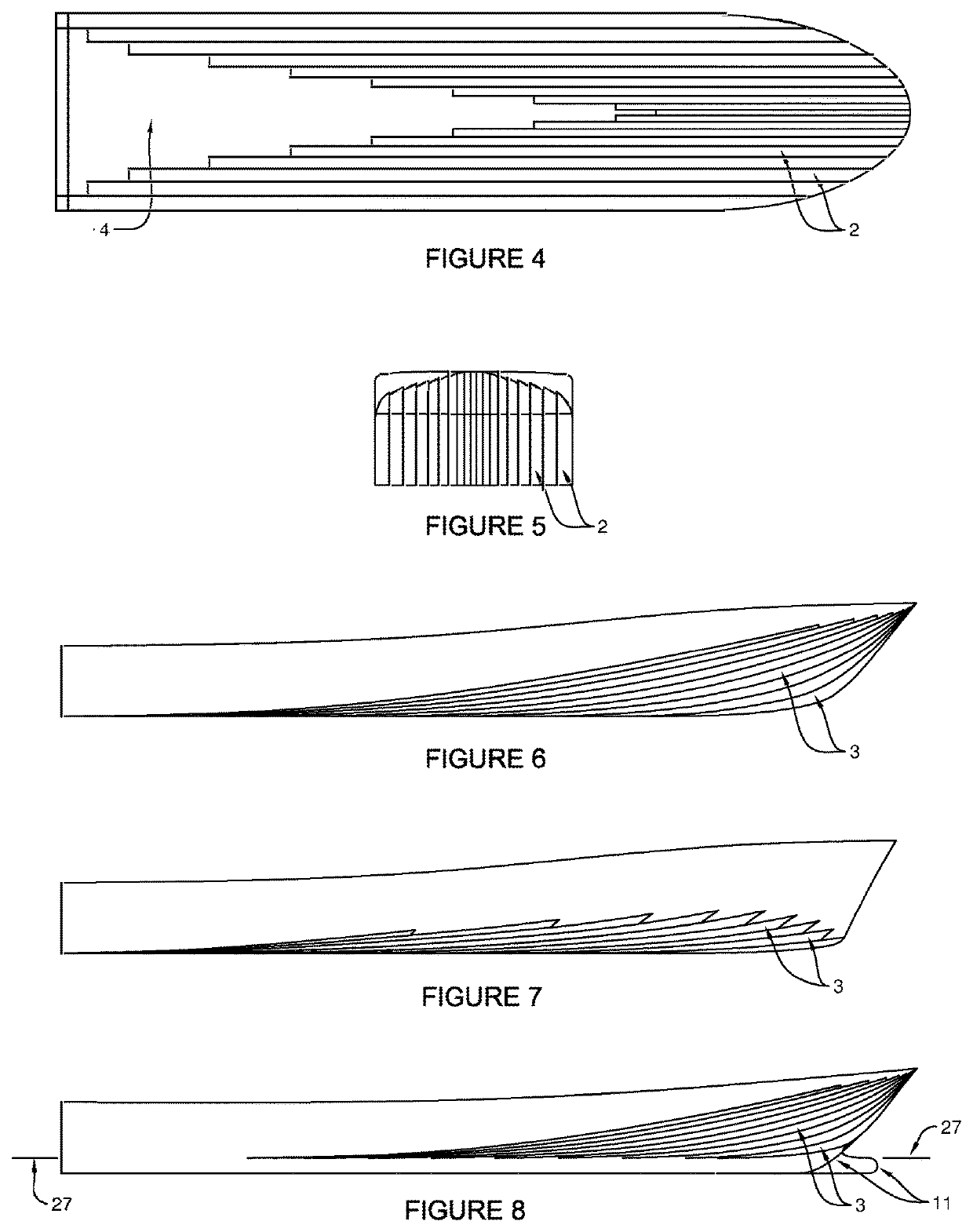

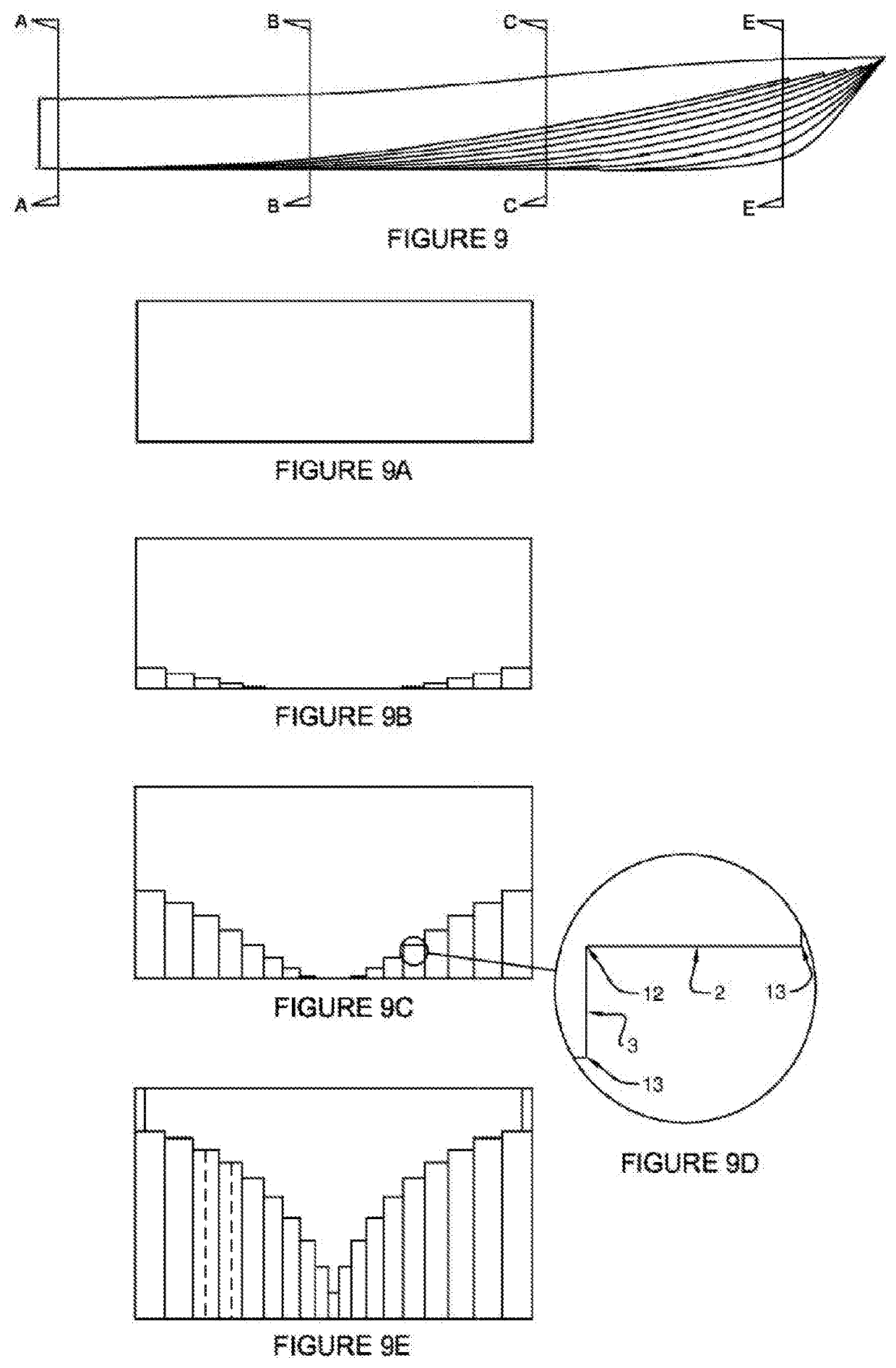

[0072]With reference to FIG. 1, there is shown a boat hull 1 according to a preferred embodiment of the invention. The boat hull 1 comprises a plurality of chines 2 extending downwardly from a bow 10 of the hull 1 towards a stern 7 or a base 4 of the hull 1. Each chine 2 is, in transverse cross section, substantially straight and substantially horizontal, as can be seen in FIG. 9D. Each chine 2 is also arranged so that a centreline or a line along the centre of the outer surface of the chine 2 lies in a plane which is parallel to a central plane of an adjacent chine 2, i.e. the adjacent chine is also configured so that a centreline of the chine lies in a plane, as indicated by the exemplary dashed line planes in FIG. 1 and exemplary dashed centrelines in FIG. 9E. Accordingly, although the chines 2 are inclined and offset from each other, in an underneath view, as illustrated in FIG. 4, the chines 2 appear parallel.

[0073]As can be seen in FIG. 9D, a substantially vertical surface 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com