Clamping ring and shell structure having the same

a technology of a shell structure and a clamping ring, which is applied in the direction of insulated conductors, cables, conductors, etc., can solve the problems of premature deformation and fracture, reduced service life prone to deformation and fracture of the joint, so as to reduce the damage of the clamping ring, improve the yield and service life of the finished product, and reduce the effect of fracture damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

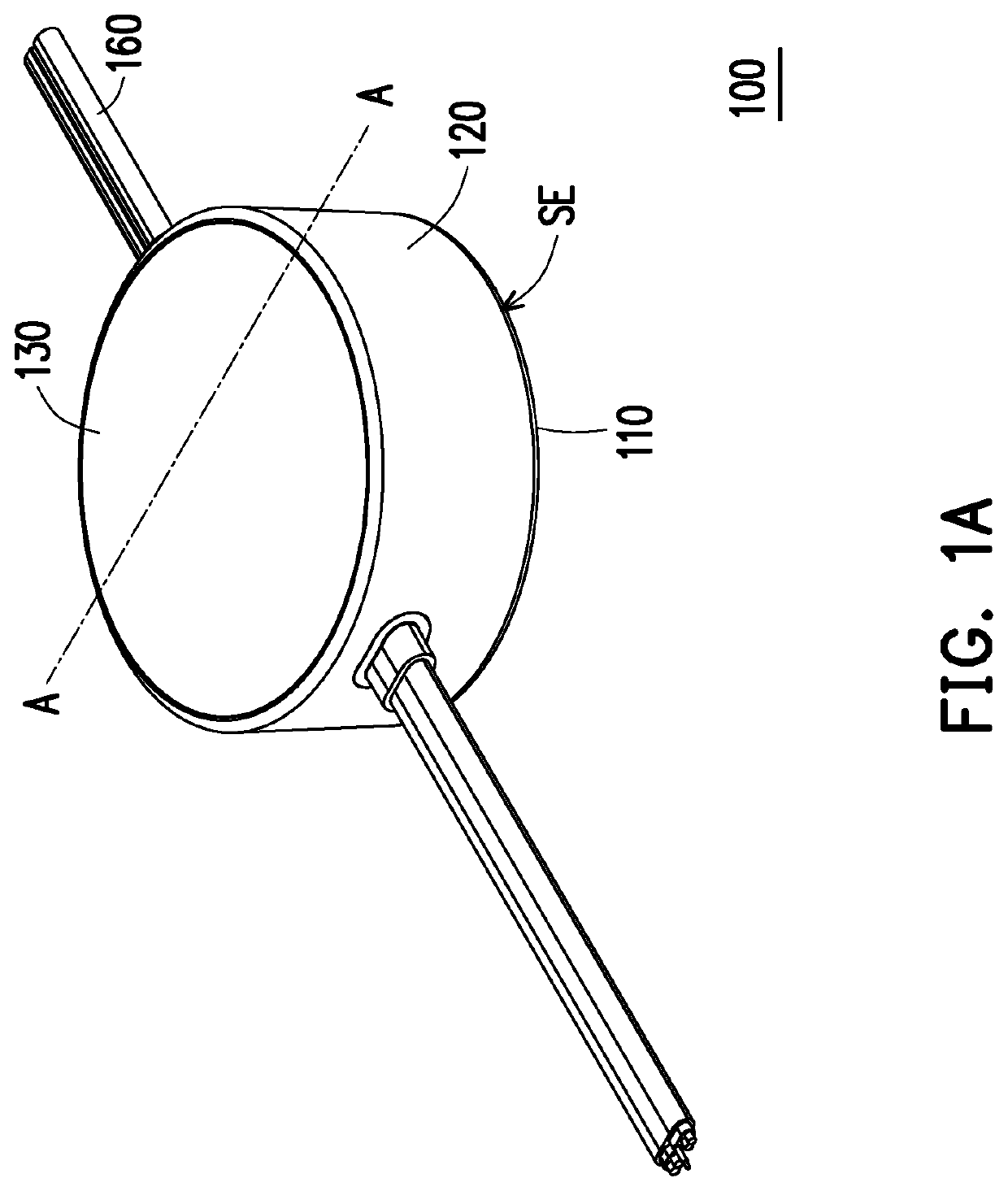

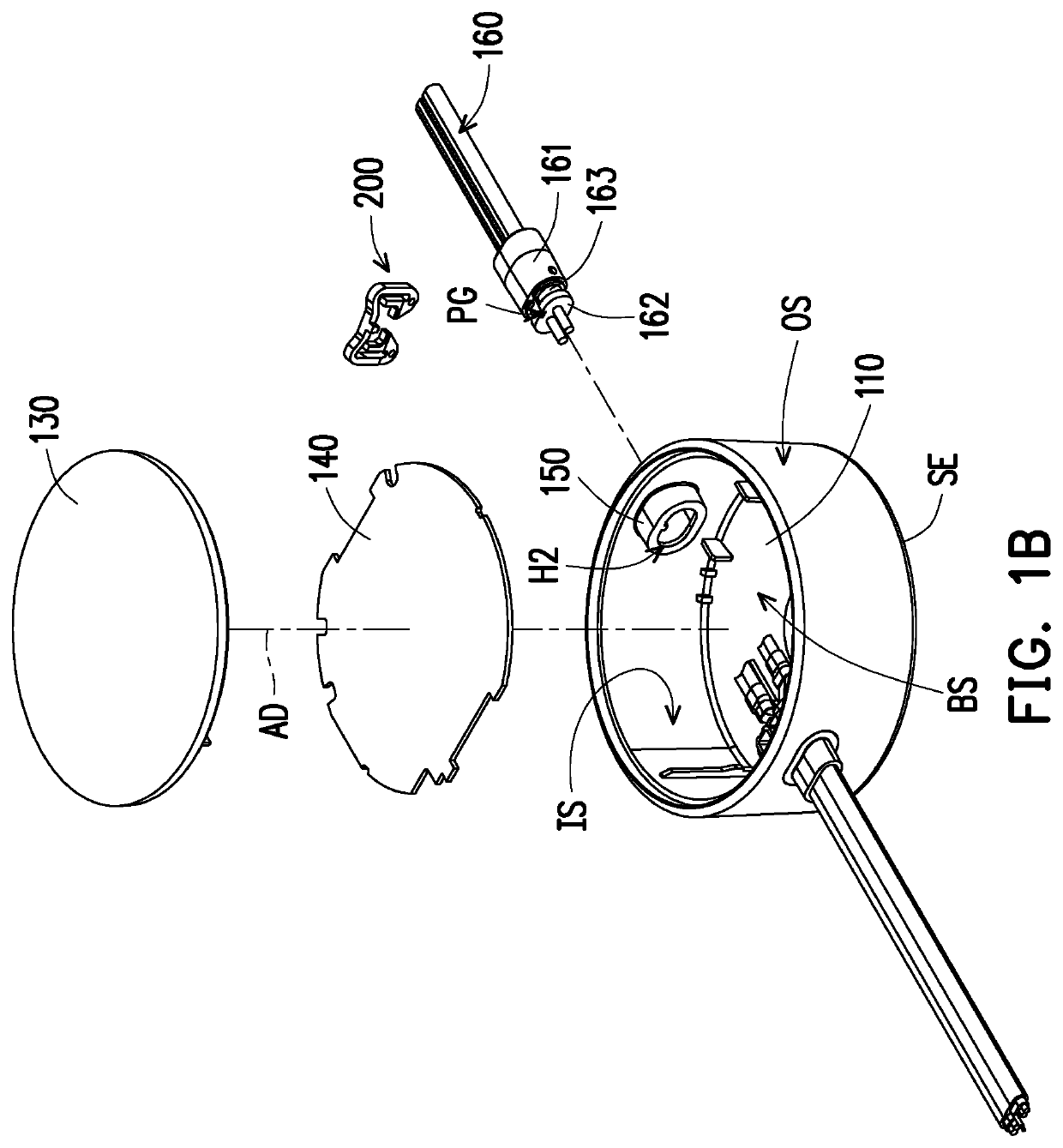

[0022]FIG. 1A is a perspective view of a shell structure according to an embodiment of the present invention. FIG. 1B is an exploded view of the shell structure of FIG. 1A.

[0023]Referring to FIG. 1A and FIG. 1B, a shell structure 100 of the present invention is adapted to carry a circuit element and is for example applied to a consumer electronic, electronic equipment, or power conversion adapter. The power conversion adapter is adapted to convert an external power source into a voltage and current value of a required specification after being transformed and rectified to be supplied to an electronic product and electronic equipment.

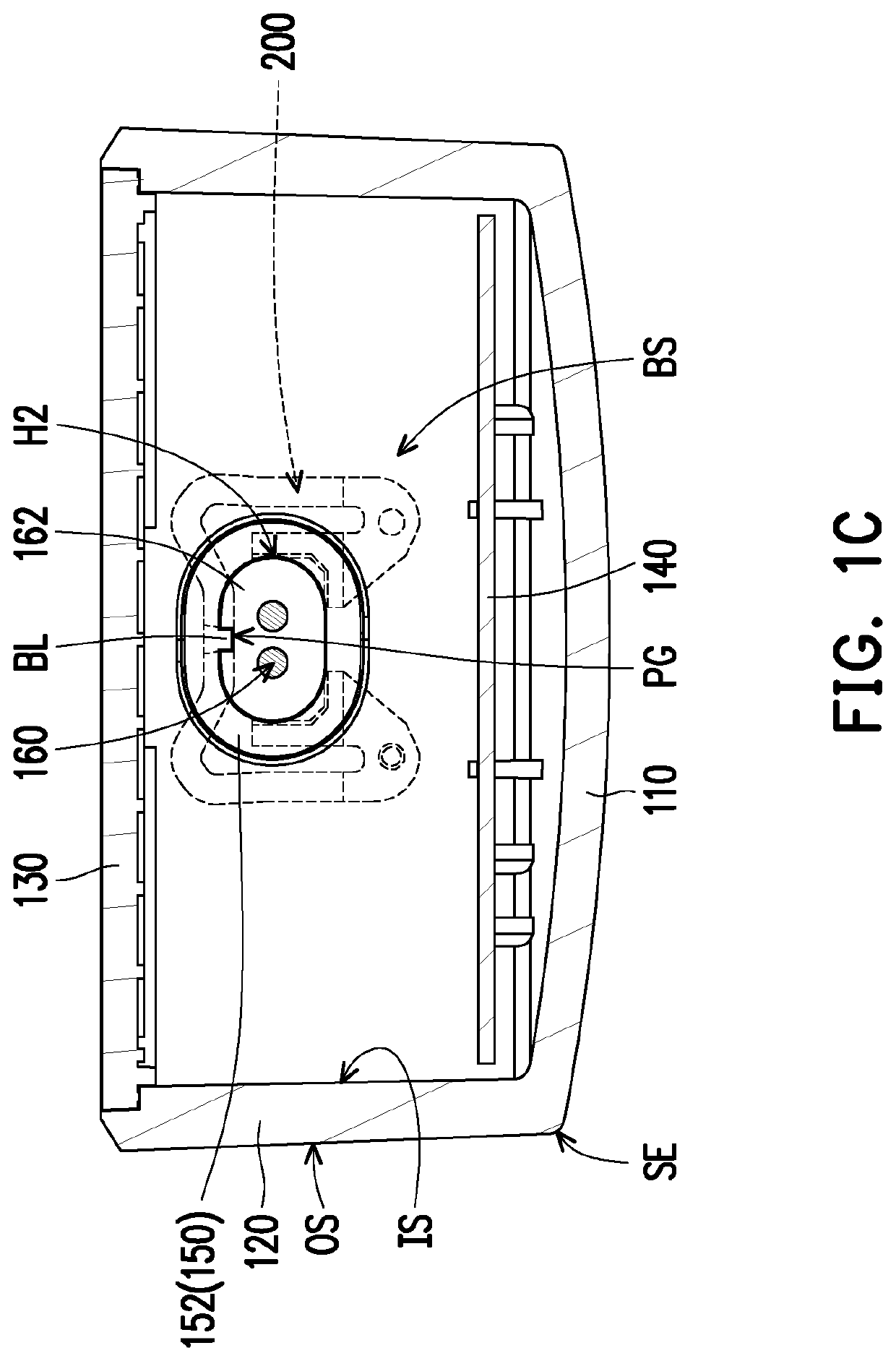

[0024]FIG. 1C is a cross section of the shell structure and clamping ring of FIG. 1A along section line A-A. FIG. 1D is an enlarged view of the wire of FIG. 1B through a shell structure. FIG. 1E is an enlarged view of a connecting portion of the shell structure of FIG. 1B.

[0025]The shell structure 100 of the present invention includes a substrate 110, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com