Latent heat accumulator system comprising a latent heat accumulator and method for operating a latent heat accumulator system

a technology of latent heat accumulator and latent heat, which is applied in the direction of indirect heat exchangers, heating types, lighting and heating apparatus, etc., can solve the problems of damage or even destruction of heat exchanger pipes, uncontrollable ice storage devices, etc., and achieve the effect of providing heat and cold quickly and efficiently and short response tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]In the figures, identical or equivalent components are numbered with identical reference numerals. The figures merely show examples and are understood to be non-limiting.

[0037]Direction terminology used below with terms such as “left,”“right,”“top,”“bottom,”“in front of,”“behind,”“after,” and the like are only used to improve the understanding of the figures and are never intended to represent a limitation of the generality. The represented components and elements, their design and use can vary depending on the considerations of a person skilled in the an and can be adapted to the respective applications.

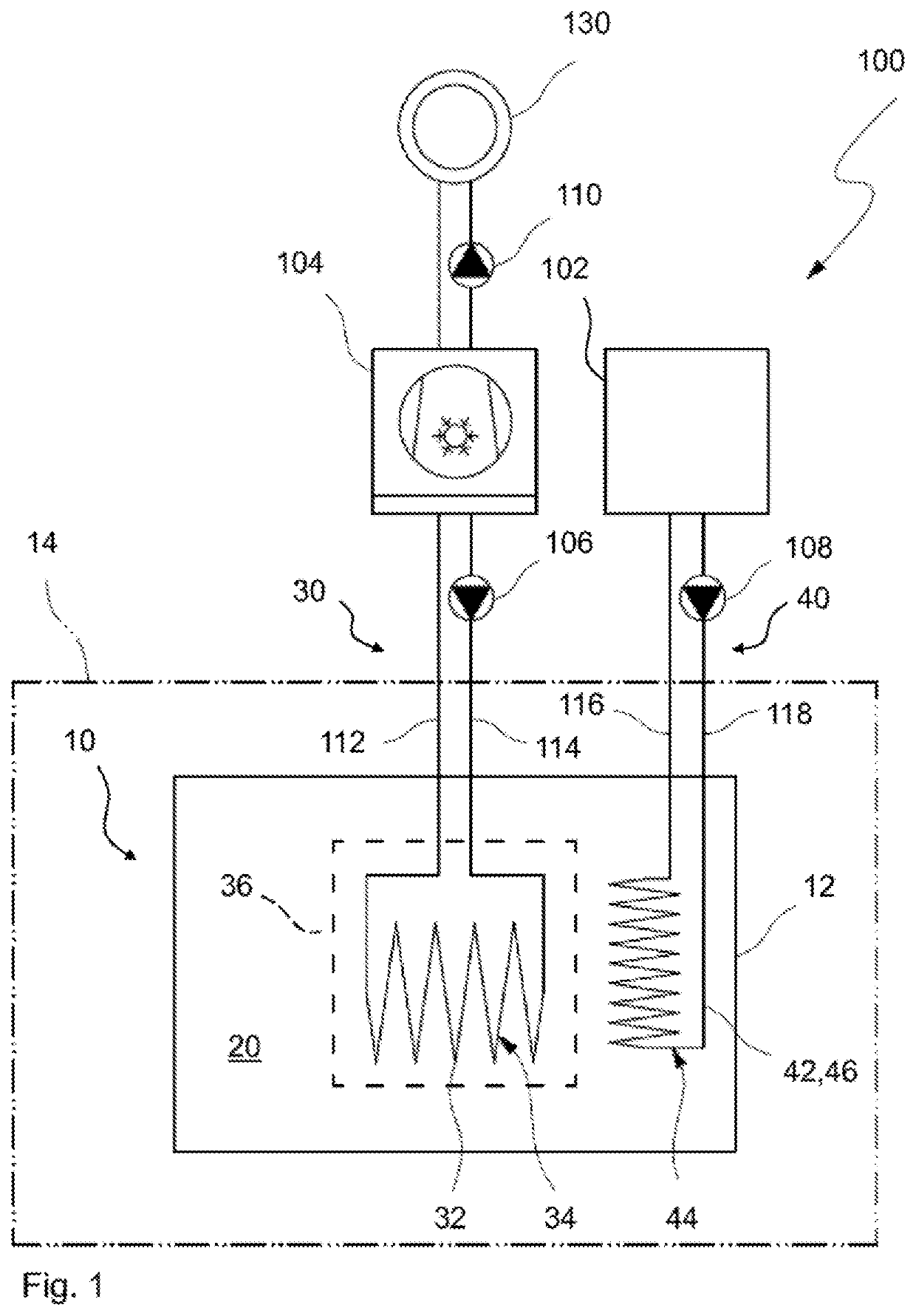

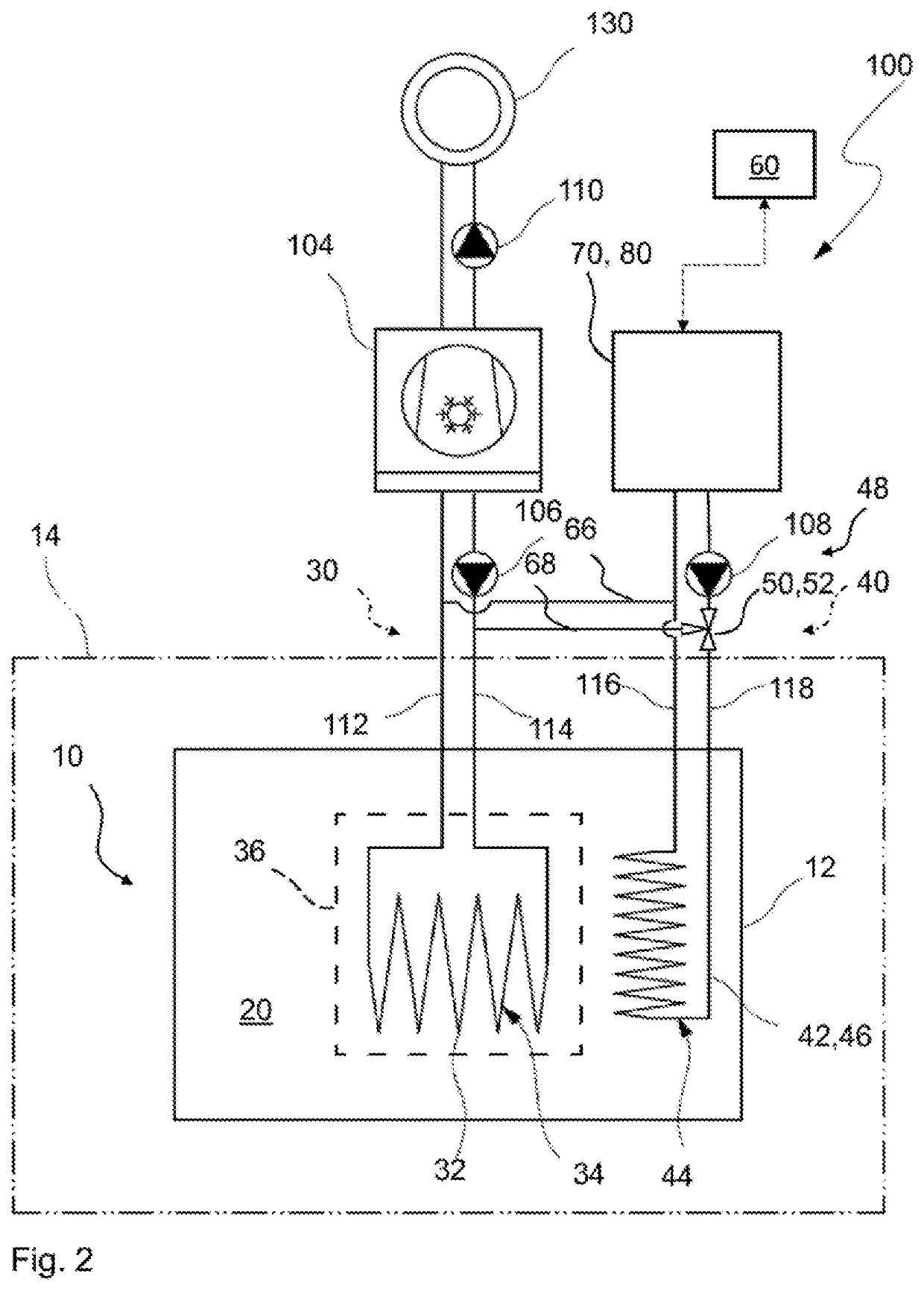

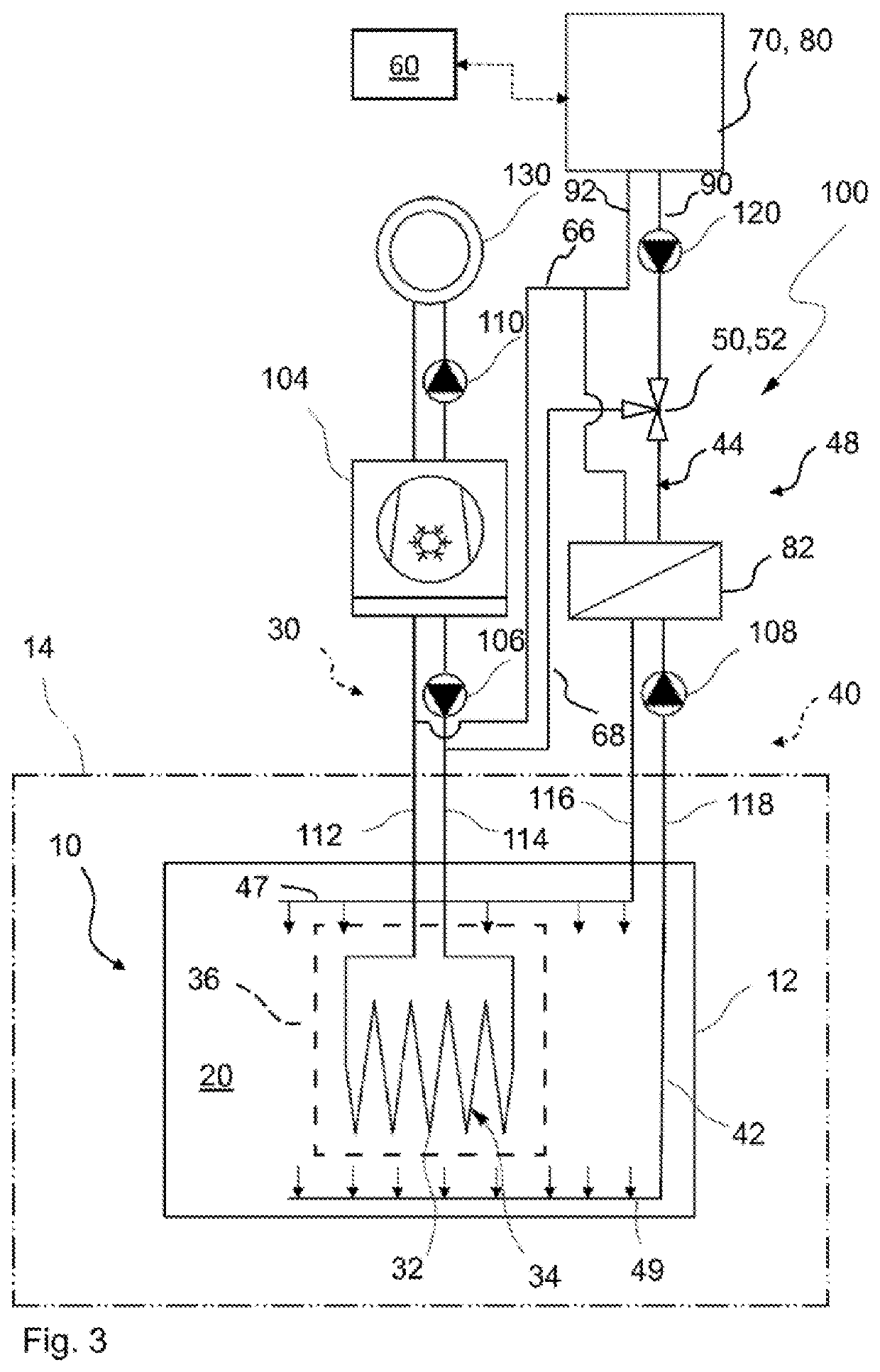

[0038]FIG. 1 represents a latent heat storage system 100 during normal operation. The latent heat storage system 100 comprises a latent heat storage device 10 which contains a storage medium 20 with latent heat, for example, water. Furthermore, the latent heat storage system 100 comprises an extraction circuit 30 which, during normal operation, in accordance with the intended ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com