Sensor package structure

a technology of package structure and sensor, applied in the direction of semiconductor device details, semiconductor/solid-state device details, radiation control devices, etc., to achieve the effect of improving glare issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

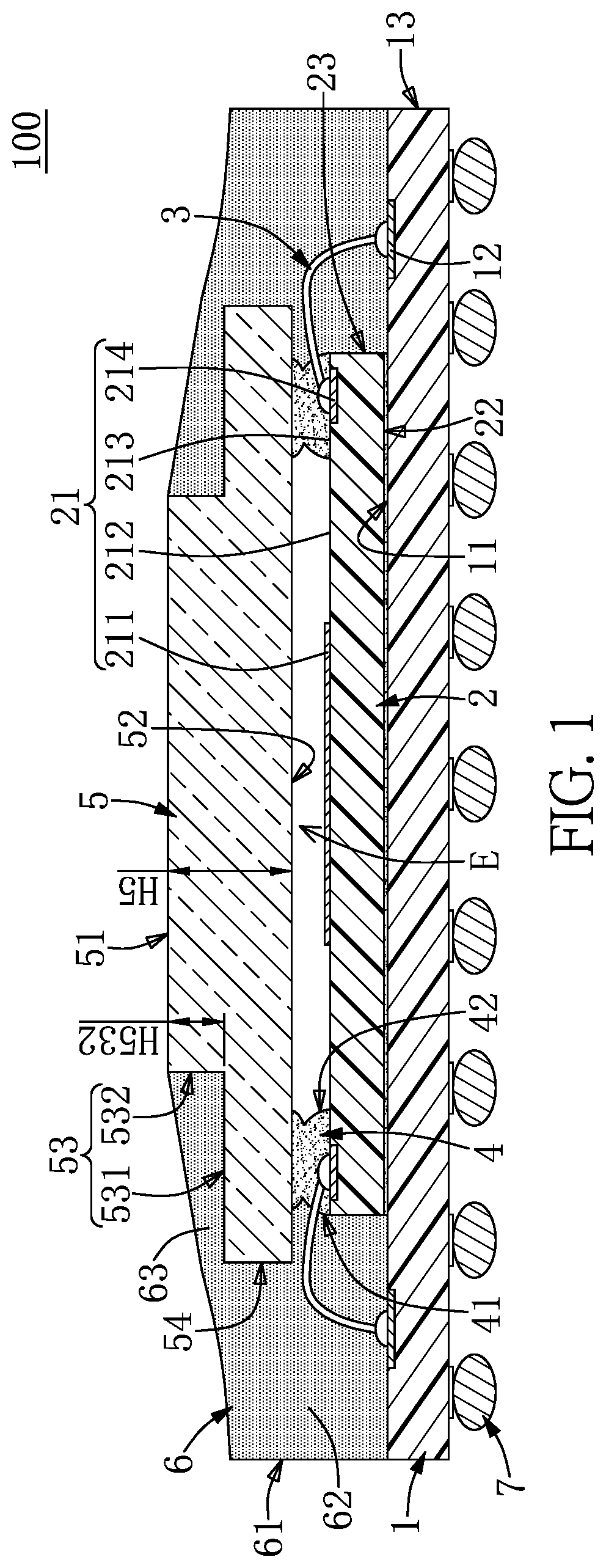

[0013]Referring to FIG. 1, a first embodiment of the present disclosure provides a sensor package structure 100. The sensor package structure 100 includes a substrate 1, a sensor chip 2 disposed on the substrate 1, a plurality of metal wires 3 electrically coupling the substrate 1 and the sensor chip 2, a ring-shaped support 4 disposed on the sensor chip 2, a light permeable board 5 disposed on the ring-shaped support 4, an opaque package body 6 formed on the substrate 1, and a plurality of solder balls 7 disposed on a bottom surface of the substrate 1.

[0014]It should be noted that the drawings of the present embodiment are cross-sectional views for the sake of easily describing the sensor package structure 100 of the present embodiment, and portions of the sensor package structure 100 not shown in the drawings shall have corresponding structures. For example, FIG. 1 shows only two of the metal wires 3 and one row of the solder balls 7, but portions of the sensor package structure 1...

second embodiment

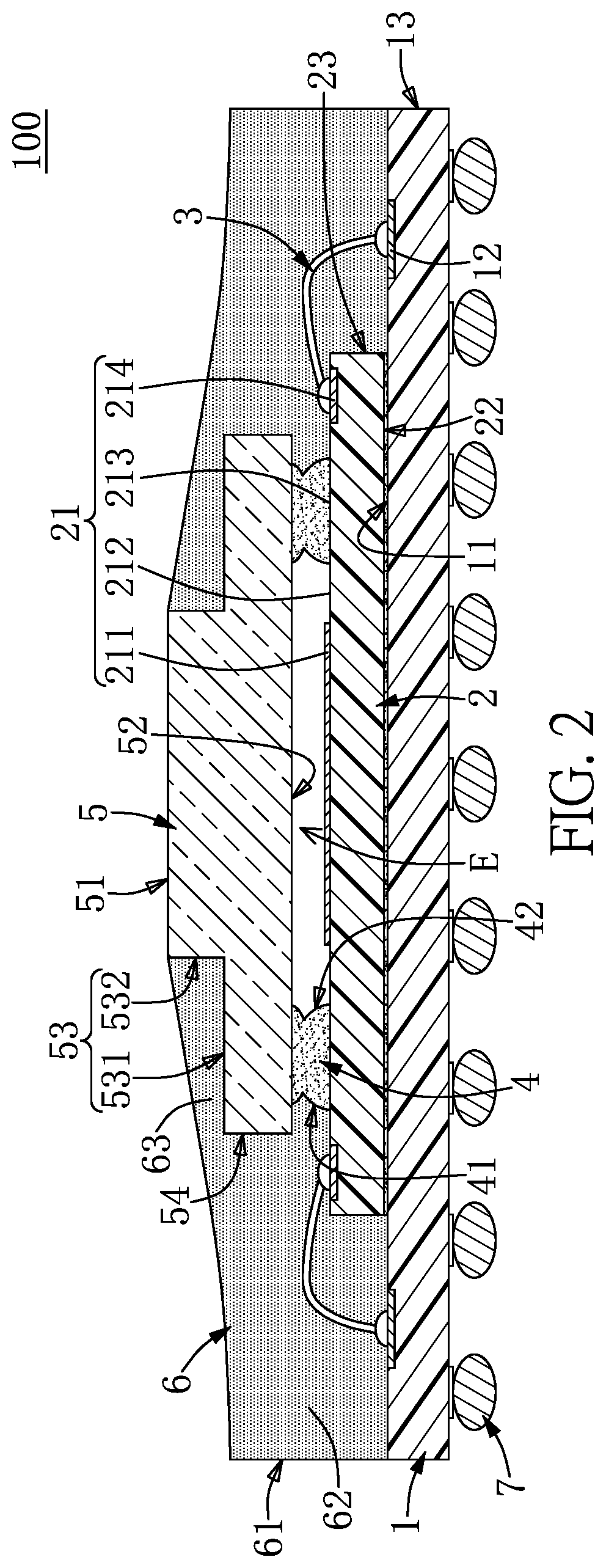

[0025]As shown in FIG. 2, a second embodiment of the present disclosure is provided. The present embodiment is similar to the first embodiment, so identical parts shall not be recited again. The differences between the present and the first embodiment will be described in the following.

[0026]Along the horizontal direction of FIG. 2 of the present embodiment, an outer diameter of the light permeable board 5 is less than that of the sensor chip 2. Moreover, the second pads 214 of the sensor chip 2 are arranged outside of the ring-shaped support 4, so that the metal wires 4 are arranged outside of the ring-shaped support 4 and are entirely embedded in the main portion 62 of the opaque package body 6. According to the first and second embodiments, each of the metal wires 4 of the present disclosure can be at least partially embedded in the main portion 62 of the opaque package body 6.

third embodiment

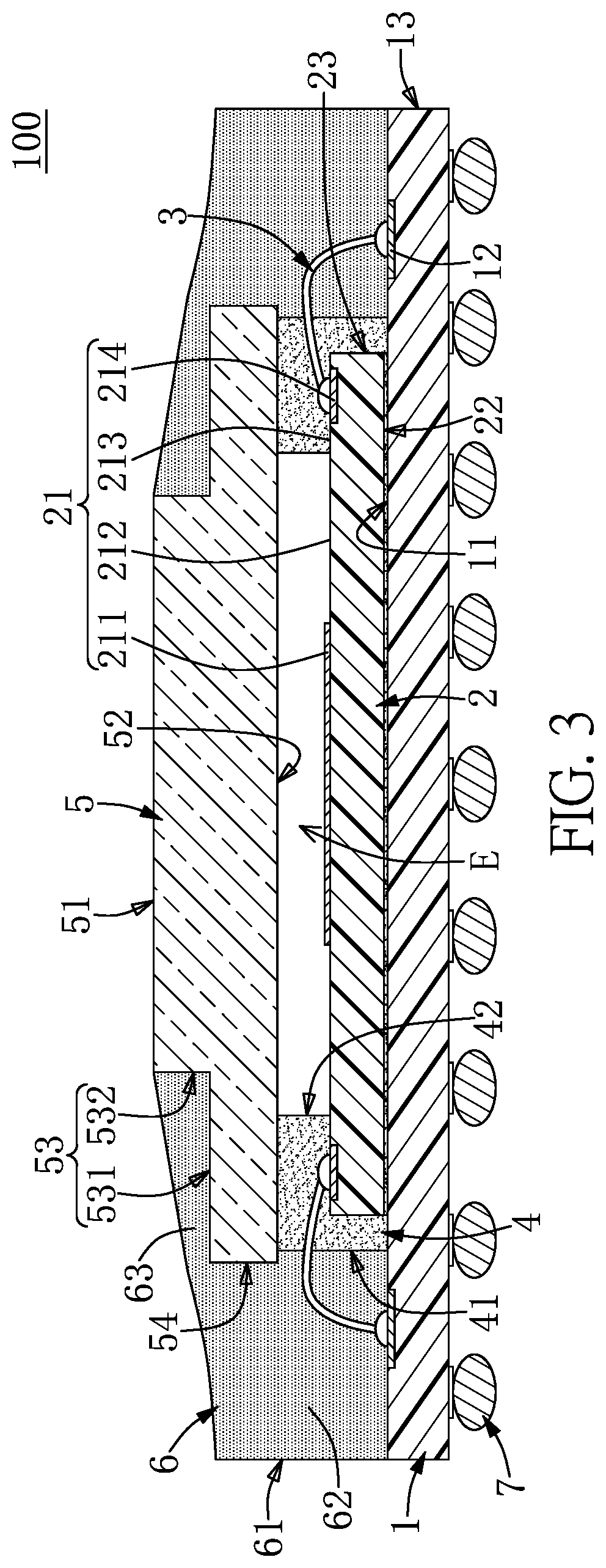

[0027]As shown in FIG. 3, a third embodiment of the present disclosure is provided. The present embodiment is similar to the first embodiment, so identical parts shall not be recited again. The differences between the present and the first embodiment will be described in the following.

[0028]In the present embodiment, the volume of the ring-shaped support 4 is increased to embed a portion of each of the metal wires 3 and further cover the outer lateral side 23 of the sensor chip 2, and the other portion of each of the metal wires 3 is embedded in the main portion 62 of the opaque package body 6.

[0029]In conclusion, the sensor package structures of the present disclosure are constructed through collocating the light permeable board and the opaque package body (e.g., the first surface is at least partially exposed from the opaque package body, and the inner lateral side of the ring-shaped support is arranged in a projection area formed by orthogonally projecting the platform surface on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| permeable | aaaaa | aaaaa |

| light permeable | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com