Rotating Control Device Clamping Mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

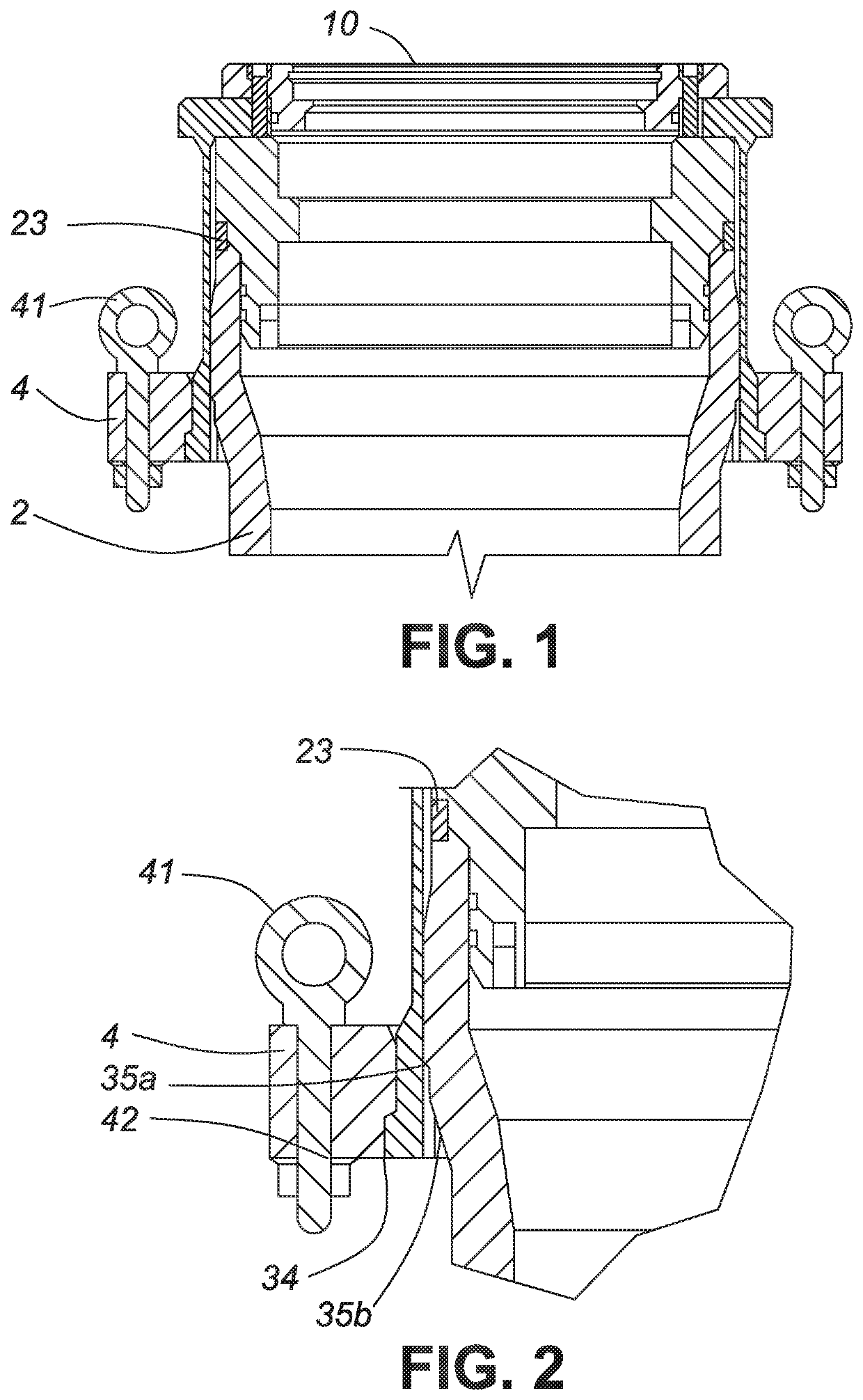

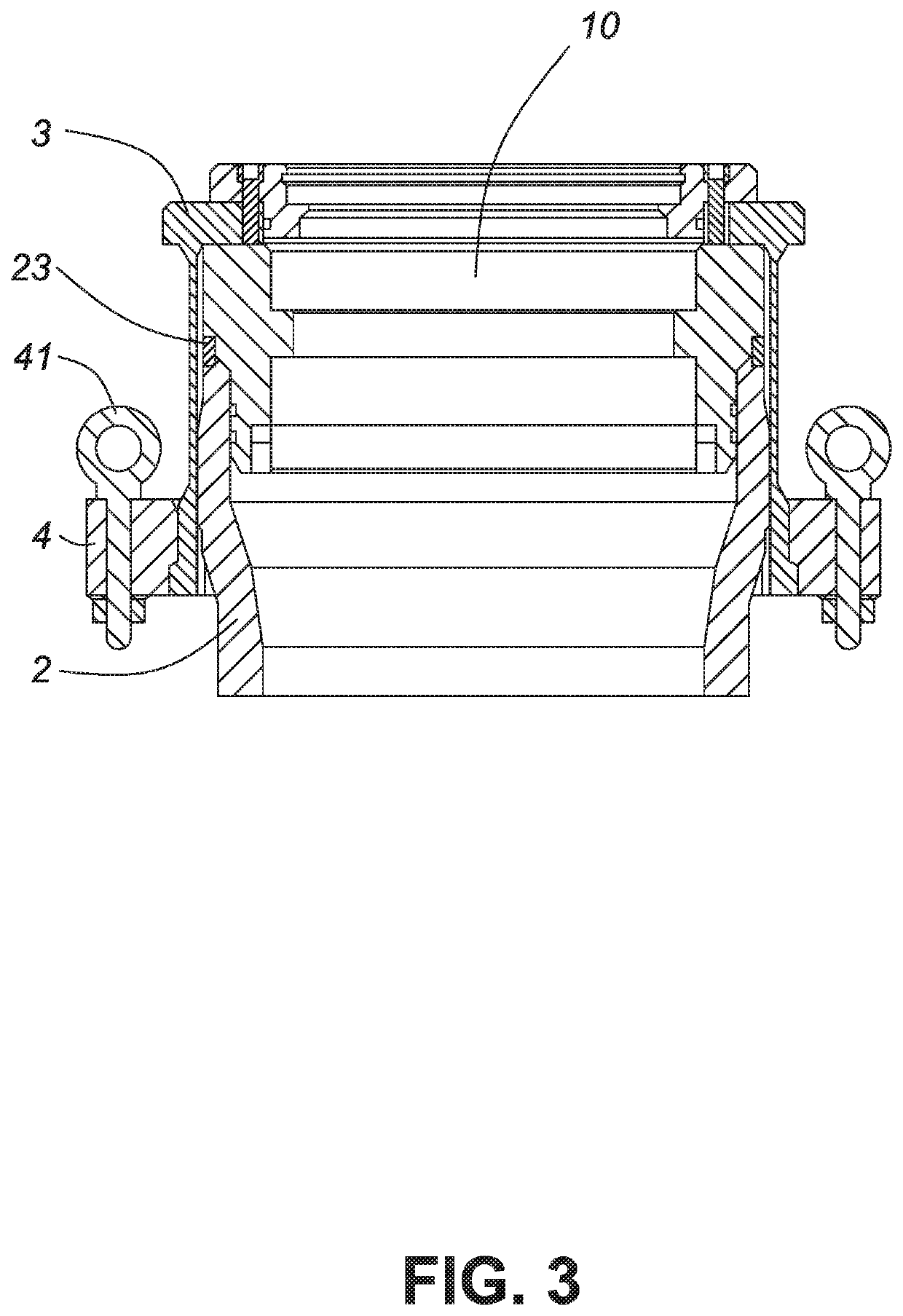

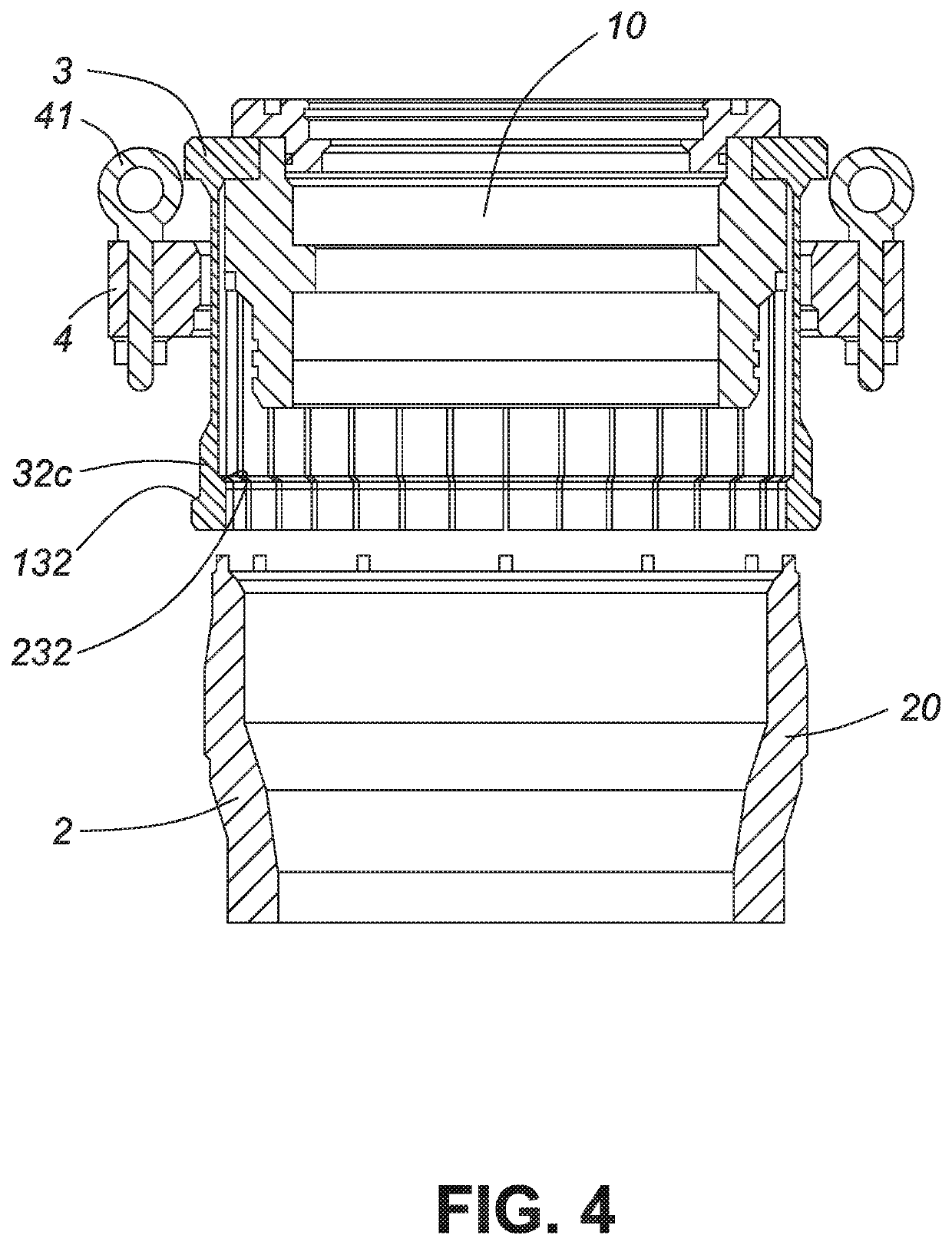

[0042]The clamping mechanism is preferably a collet which is viewable in FIGS. 1 and 2. The main benefits of the closure arrangement according to the present invention are that: no one has to climb onto the BOP stack to install or remove the bearing; and it does not require the use of hydraulics. The former is a clear safety advantage over other known devices and the latter relieves the amount of equipment required for the installation of an RCD.

[0043]According to a preferred embodiment of the present invention, the closure arrangement consists of 4 separate pieces: bearing assembly, body, closure collet, and collet lock ring.

[0044]FIGS. 1, 2 and 3 depict the collet lock ring captured between two pieces on the bearing assembly with clearance and are not rotationally locked. The outside top of the body has two different tapered faces which oppose each other (tapered in opposite directions). The upward facing taper is shallower than the downward facing one so the installation force is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap