Filter Element Having an End-Side Stand

a filter element and end-side stand technology, applied in the direction of filtration separation, lubricant mounting/connection, separation process, etc., can solve the problem of radial seal and/or sealing element damage, and achieve the effect of easy and economical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

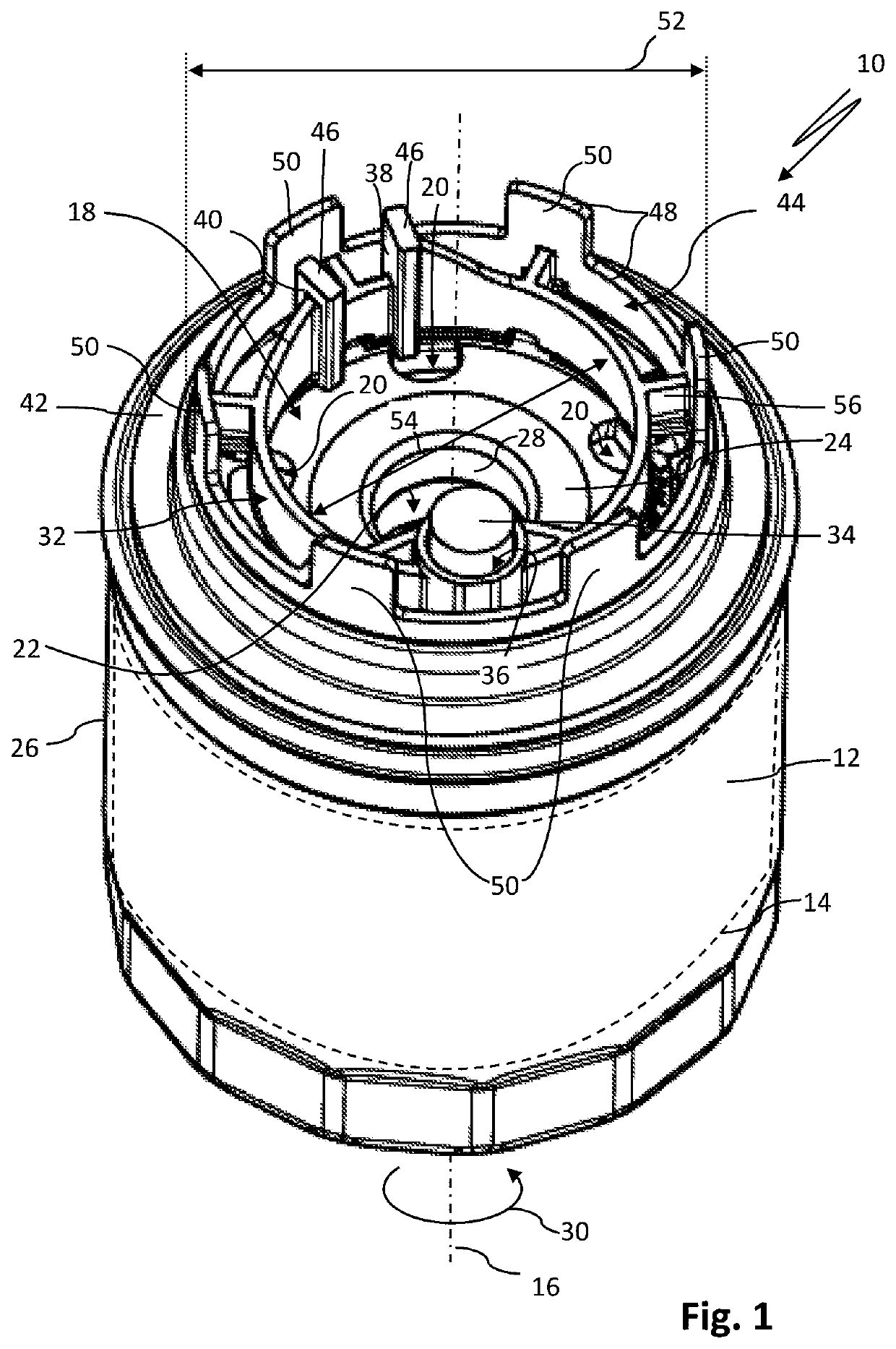

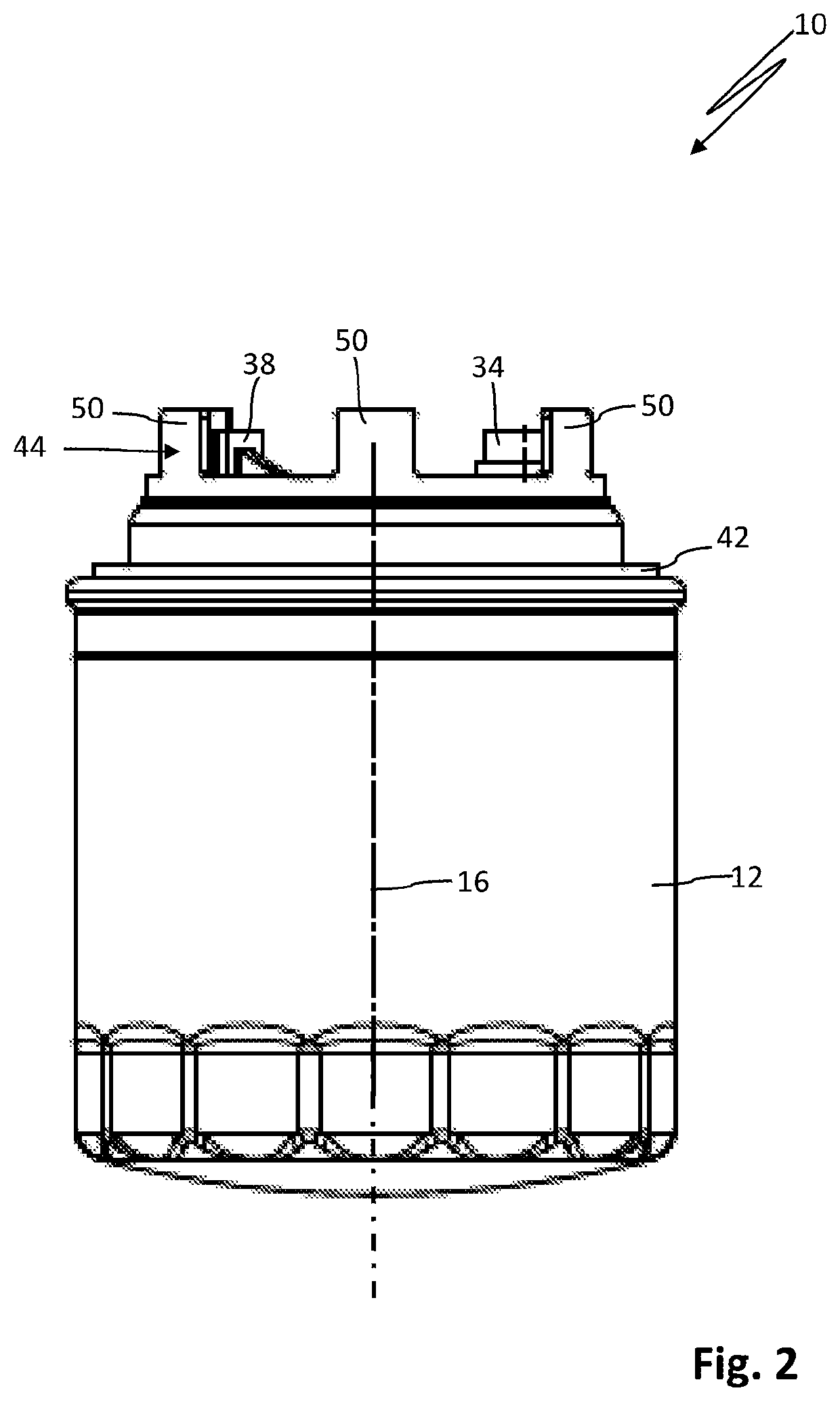

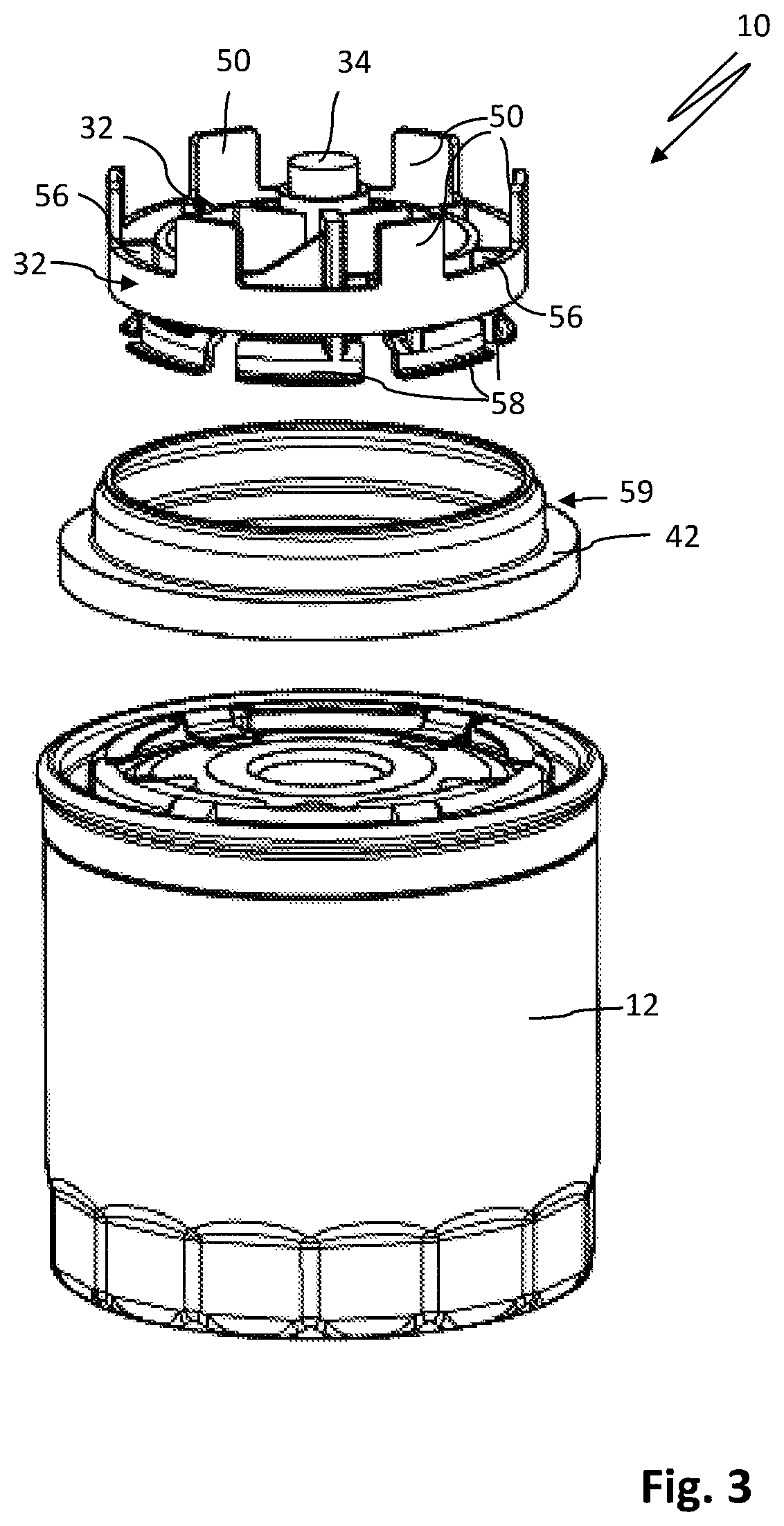

[0032]FIG. 1 shows a filter element 10 for filtering a fluid, in particular lubricant oil for the internal combustion engine of a motor vehicle, which is embodied here in the form of an exchangeable filter cartridge. Such exchangeable filter cartridges are also referred to as spin-on filter cartridges or spin-on filter elements. The filter element 10 comprises thus a filter housing 12 of metal or plastic material and a filter insert 14 with a filter medium arranged captively in the filter housing 12 which is illustrated in FIG. 1 only in a greatly simplified schematic way with dashed line. The longitudinal axis of the filter element 10 is identified by 16.

[0033]The filter element 10 comprises an end face 18 with several inlet openings 20 for the fluid to be filtered and with a single centrally arranged outlet opening 22 for the filtered fluid. The inlet openings 20 are arranged here in an exemplary fashion spaced apart from each other in a ring shape about the longitudinal axis 16. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com