Method for Filling a Nautical Hydraulic Steering System

a technology of hydraulic steering system and nautical steering system, which is applied in the direction of steering rudder, vessel construction, marine propulsion, etc., can solve the problems of messy and inability to do the manual process alon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

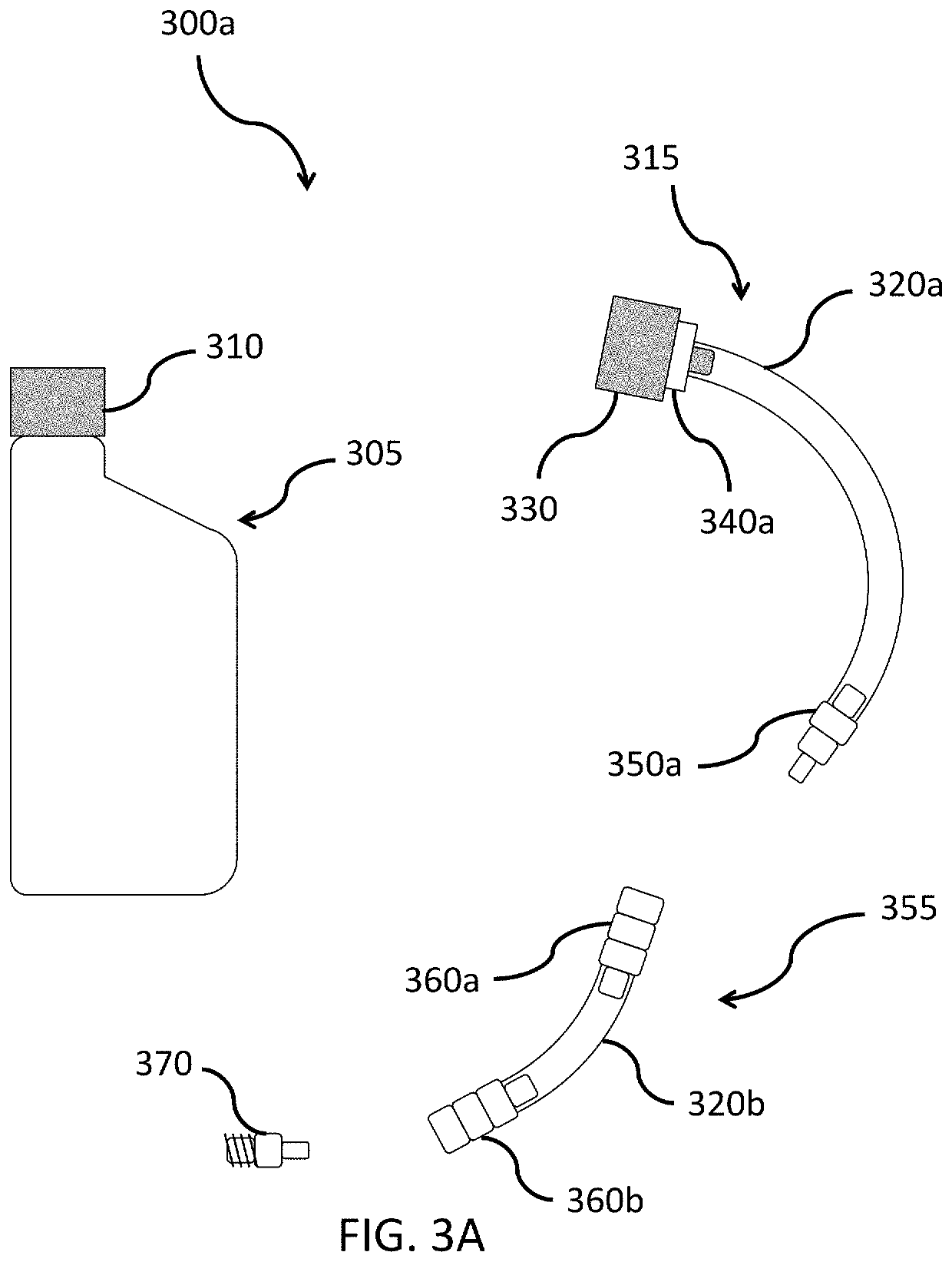

[0023]FIG. 3A is a depiction of helm-side components 300a of the system for filling hydraulic oil from nautical steering systems. The components 300a include a bottle of hydraulic oil 305, a bottle attachment 315a, a fluid lock 355, and a helm fill port adapter 370. The bottle of hydraulic oil 305 has a lid 310. The bottle attachment 315a includes a lid adapter 330, which is secured to the first hose 320a by a fastener 340a on one end, and a valve 350a on the other. The fluid lock 355 is a second hose 320b with corresponding valves 360a, 360b on both sides.

[0024]In the depicted embodiment, the lid adapter 330 is an injection-molded lid designed to conform to the dimensions of the bottle lid 310 that includes an 8 mm outside diameter spout in its center. The hoses 320a, 320b, 320c are a transparent polyurethane pneumatic tubing with a 12 mm outside diameter and an 8 mm inside diameter. The fastener 340a is an Oetiker® ear clamp, and the valve 350a is a male Parker® 21 KA series quick...

second embodiment

[0028]FIG. 3B is a depiction of helm-side components 300b of the system for filling hydraulic oil from nautical steering systems. The components 300b include the bottle of hydraulic oil 305, a bottle attachment 316, a fluid lock 356, and the helm fill port adapter 370.

[0029]The bottle attachment 316 can be a cap 380 with a valve 390. The cap 380 is designed to conform to the dimensions of the bottle lid 310. The cap 380 can be made out of brass and have a ⅛″ National Pipe Tapered tap. The valve 390 can be a rectus Parker® 21KA female quick connect with a male ⅛″ National Pipe Tapered thread. The valve 390 is inserted into the tap of the brass cap 380 (shown in FIG. 3B with dashed lines).

[0030]The fluid lock 356 is a hose 320c with two valves 350b, 360c. The hose 320c is optimally long enough so that the bottle 305 can rest on top of the helm 200. The valve 350c that connects with the bottle attachment 316 can be a male Parker® 21KA series quick connect coupling that, if it does not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com