Liquid ring pump control

a technology of liquid ring pump and control ring, which is applied in the direction of liquid fuel engines, rotary piston liquid engines, machines/engines, etc., can solve the problems of cavitation, wear and failure of certain liquid ring pumps, and the liquid ring pumps can consume considerable amounts of fresh water, so as to reduce the operating cost of the liquid ring pump, reduce the operating cost, and reduce the effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

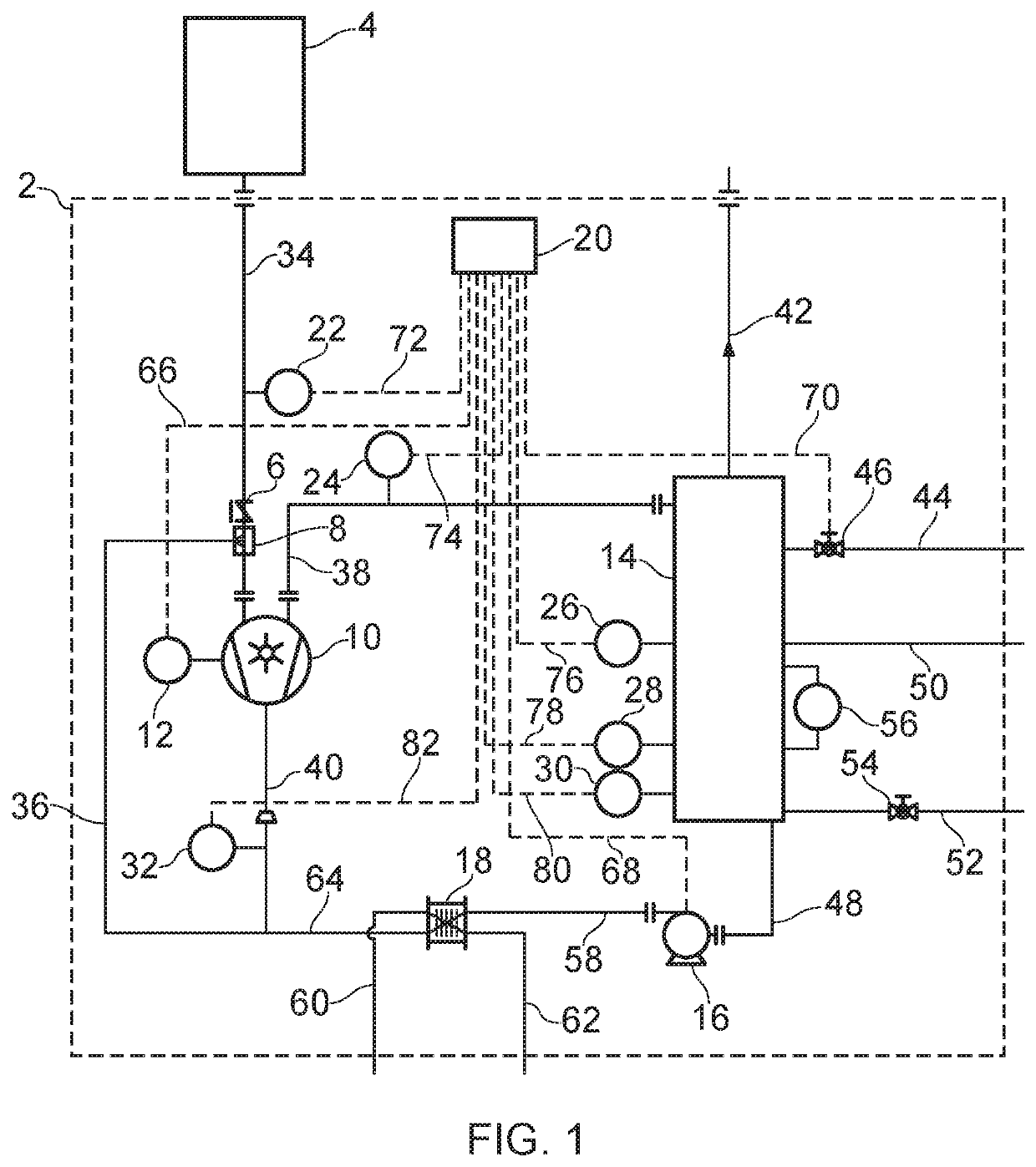

[0024]FIG. 1 is a schematic illustration (not to scale) showing a vacuum system 2. The vacuum system 2 is coupled to a facility 4 such that, in operation, the vacuum system 2 establishes a vacuum or low-pressure environment at the facility 4 by drawing gas (for example, air) from the facility 4.

[0025]In this embodiment, the vacuum system 2 comprises a non-return valve 6, one or more spray nozzles 8, a liquid ring pump 10, a motor 12, a separator 14, a pump system 16, a heat exchanger 18, a controller 20, a first pressure sensor 22, a first temperature sensor 24, a second pressure sensor 26, a first level sensor 28, a second level sensor 30, and a second temperature sensor 32.

[0026]The facility 4 is connected to an inlet of the liquid ring pump 10 via a suction or vacuum line or pipe 34.

[0027]The non-return valve 6 and the spray nozzle are disposed on the suction line 34. The non-return valve 6 is disposed between the facility 4 and the spray nozzle 8. The spray nozzle 8 is disposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com