Pressure reducer for rotary internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

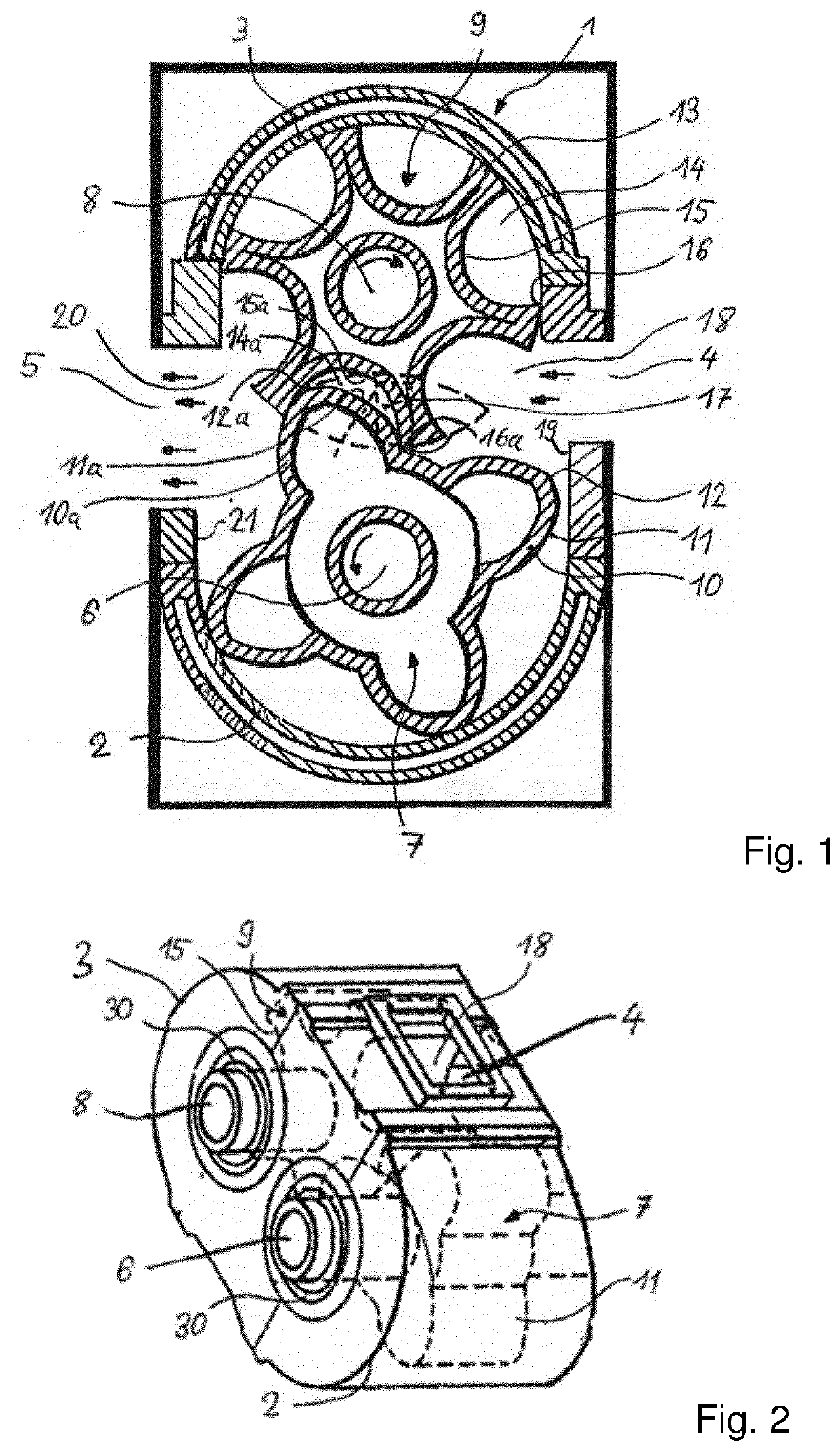

[0006]It is an object of the invention to improve a pressure reducer for a rotary internal combustion engine, in particular to provide such a pressure reducer with a high expansion capacity and enlarged mechanical potential, which needs a small number of components, and has a long service-life.

[0007]These and other objects, which will appear from the description below, are achieved by a pressure reducer for a rotary internal combustion engines set forth in the appended independent claim. Preferred embodiments are defined in the dependent claims.

[0008]In particular the objects of this invention are realized by the following technical solutions. According to the invention a pressure reducer for a rotary internal combustion engine comprises a housing, which accommodates a first shaft and a second shaft running parallel to each other through the housing. Further the pressure reducer comprises a first rotor on the first shaft and a second rotor on the second shaft. The first rotor and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com