Vaccum die casting method and a die for vaccum die casting

a die casting and vacuum die technology, applied in the field of die casting methods and dies, can solve the problems of reducing the strength of the product, reducing the efficiency of the product, so as to achieve excellent productivity and suppress casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to sufficiently understand the present disclosure, operational advantages of the present disclosure and objects accomplished by embodiments of the present disclosure, reference should be made to the accompanying drawings illustrating embodiments of the present disclosure and contents described in the accompanying drawings.

[0036]In describing embodiments of the present disclosure, detailed and repetitive descriptions for the known art related to the disclosure have been shortened or omitted where it may otherwise obscure the gist of the disclosure.

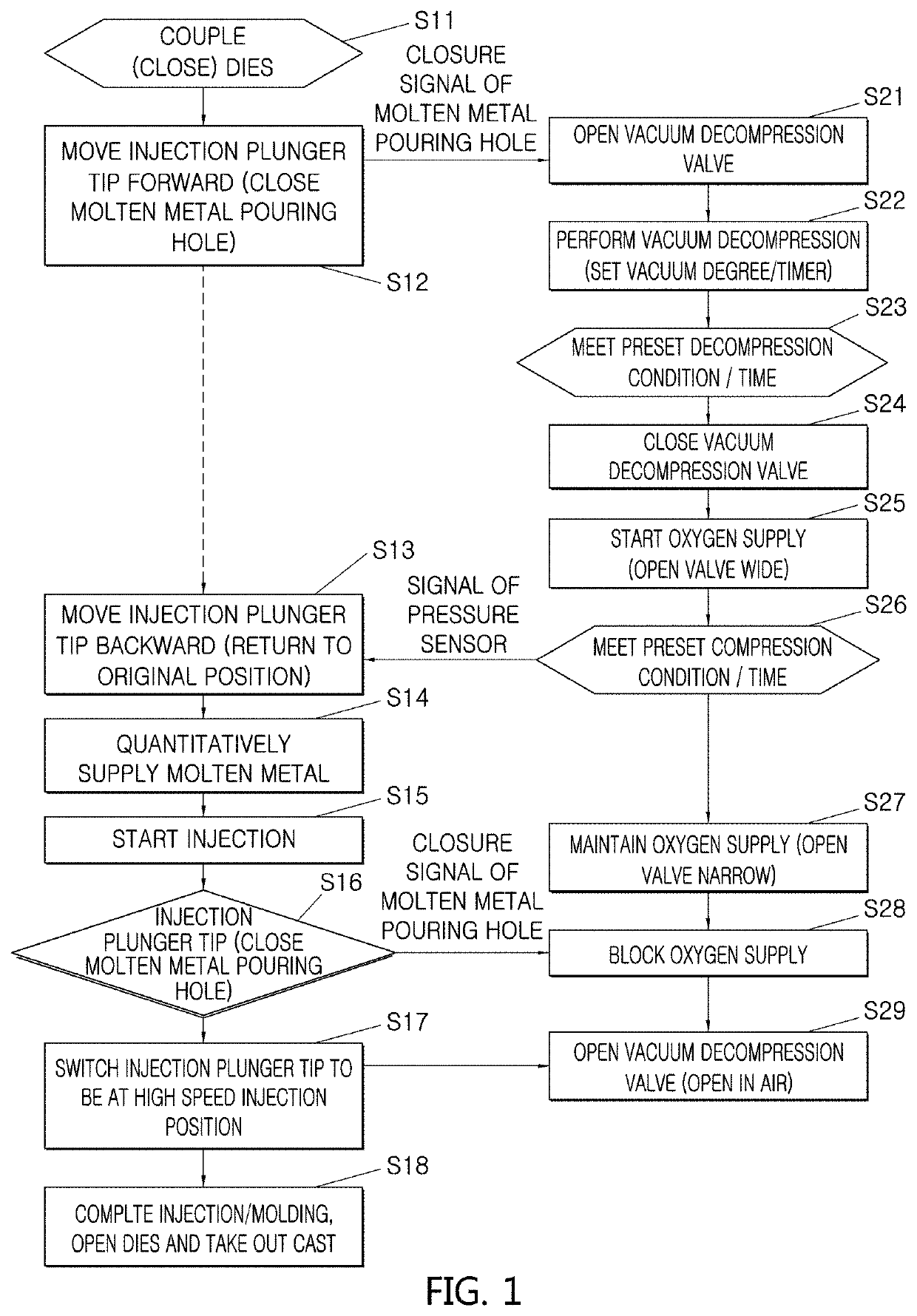

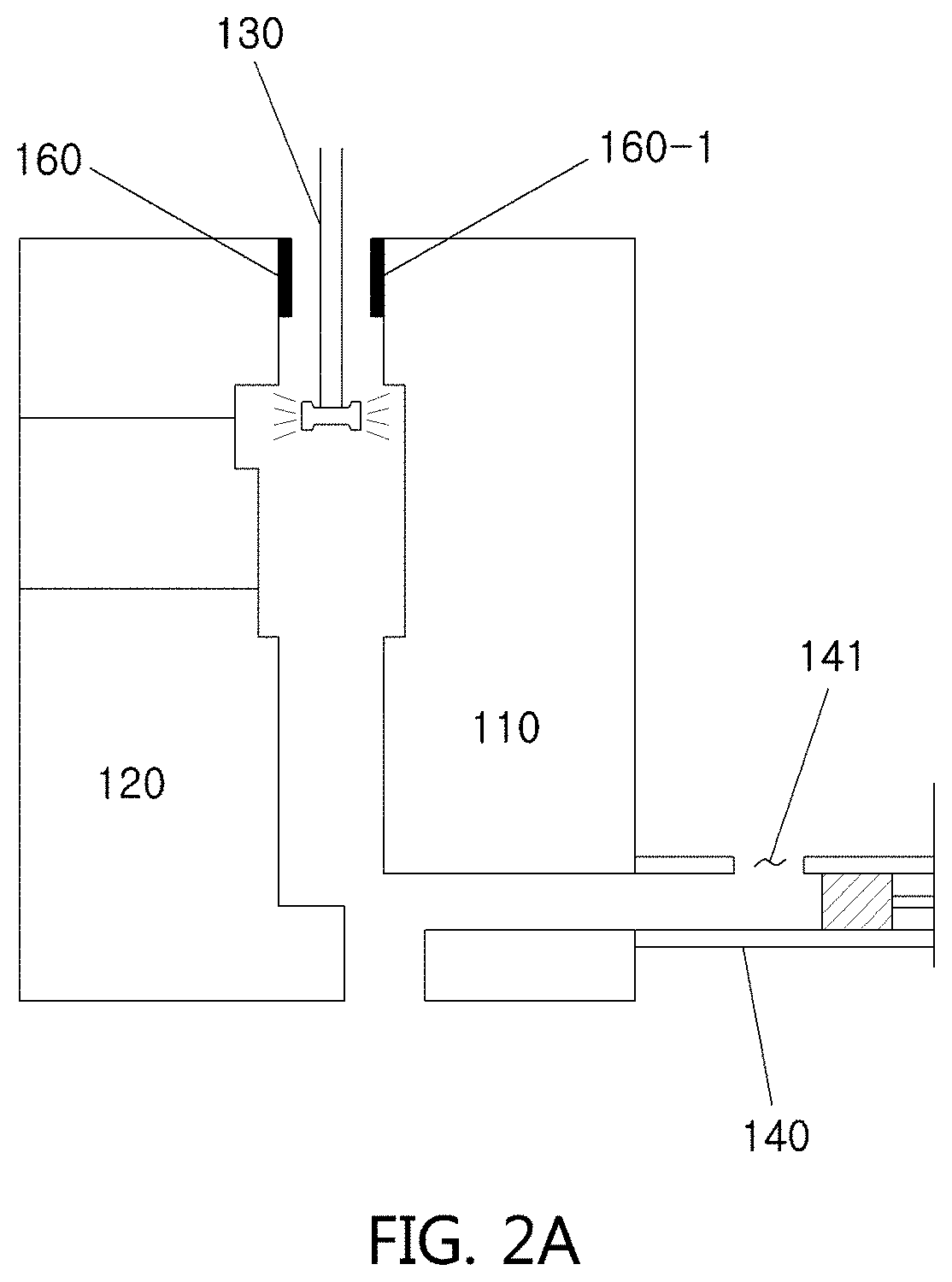

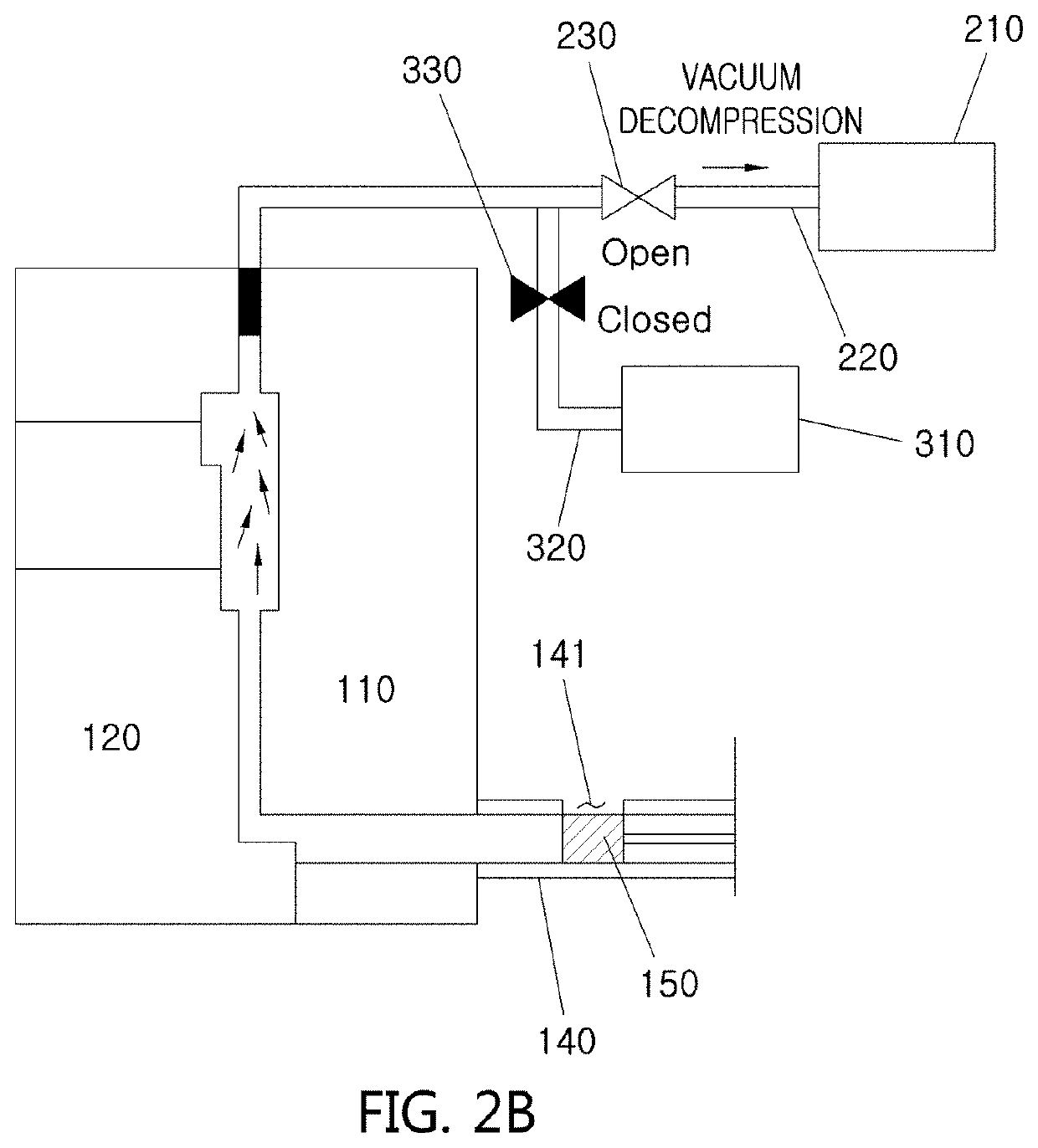

[0037]FIG. 1 is a flowchart illustrating a vacuum die casting method according to the present disclosure. FIGS. 2A, 2B, 2C, 2D, 2E, 2F and 2G sequentially illustrate a vacuum die casting method according to the present disclosure.

[0038]Hereinafter, a vacuum die casting method and a die for a vacuum die casting according to an embodiment of the present disclosure are described with reference to the flowchart of FIG. 1 and to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com