Laminated plate-type sandwich insulation shear wall with tie bolts and installation method thereof

a technology of sandwich insulation and tie bolts, which is applied in the direction of heat-proofing, other domestic articles, water-setting substance layered products, etc., can solve the problems of large stress of tie bolts, external wall and internal wall stress, and achieve the effect of increasing the strength of cast-in-place concrete and preventing surface cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]Specific implementation: laminated plate-type sandwich insulation shear walls on the current market are not provided with tie bolts, a prefabricated external wall is connected with a prefabricated internal laminated wall board through an external wall connector, and thus, the external wall connector used for connecting an external wall with an internal wall is also used for connecting the prefabricated external wall with the prefabricated internal laminated wall board.

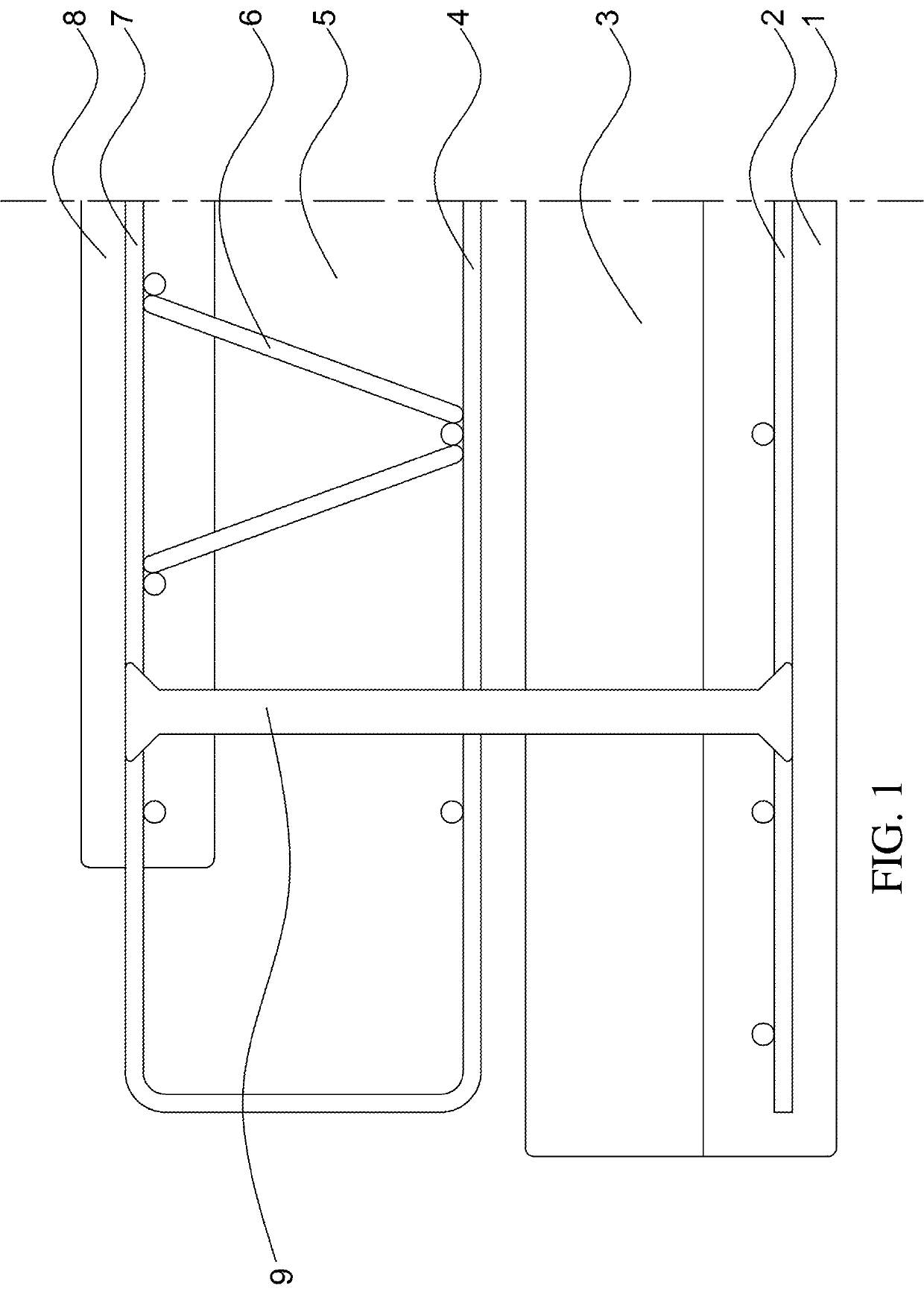

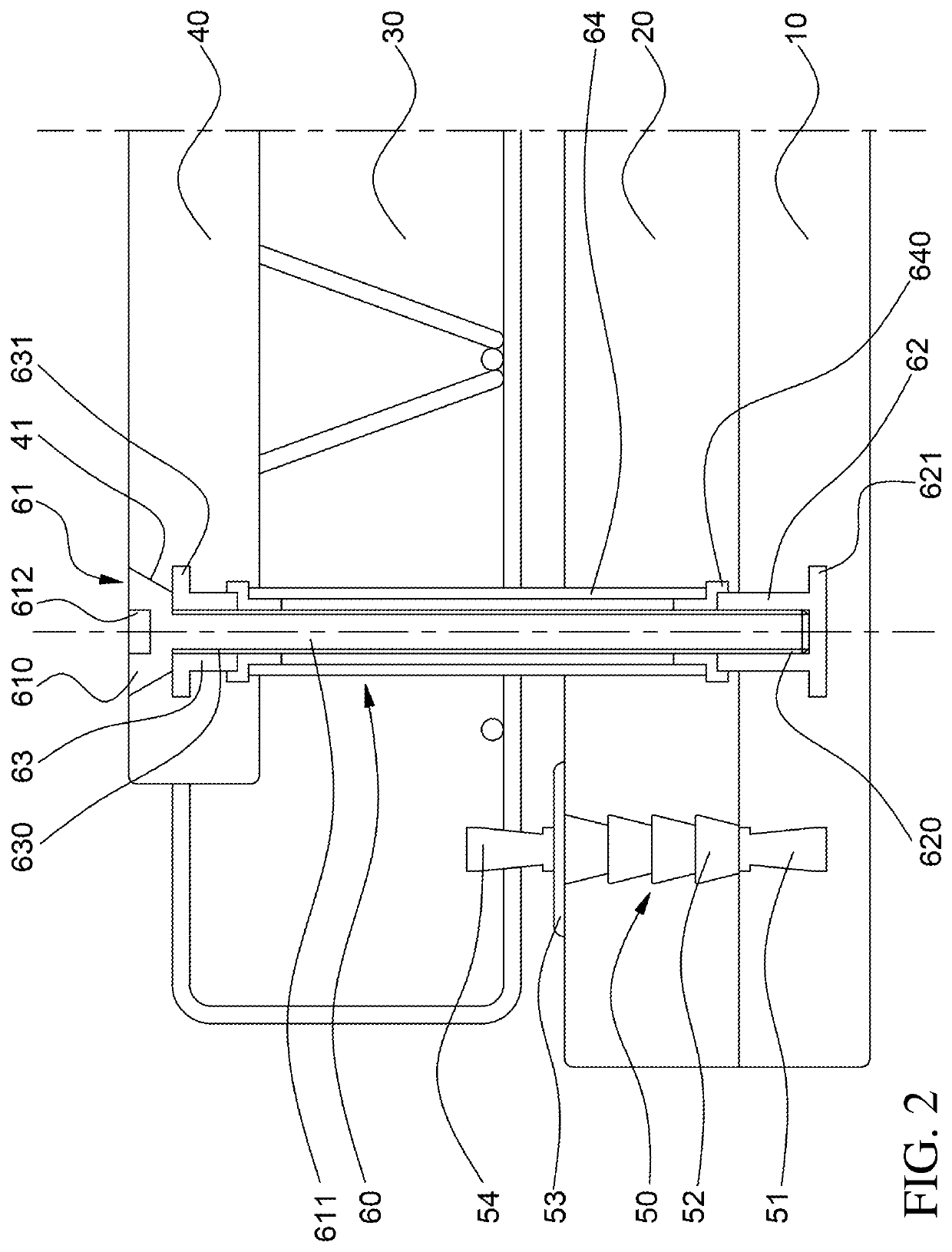

[0014]Embodiment 1: the invention is an improvement on the traditional laminated plate-type sandwich insulation shear wall system. FIG. 1 is a structural sectional view of the traditional laminated plate-type sandwich insulation shear wall. Reference Signs in FIG. 1: 1, prefabricated external wall; 2, external wall reinforcing mesh; 3, sandwich insulation layer; 4, cast-in-place concrete layer reinforcing mesh; 5, cast-in-place concrete layer; 6, truss bar; 7, prefabricated internal laminated wall board reinforci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| stress | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap