Magnetostriction element and magnetostriction-type vibration powered generator using same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

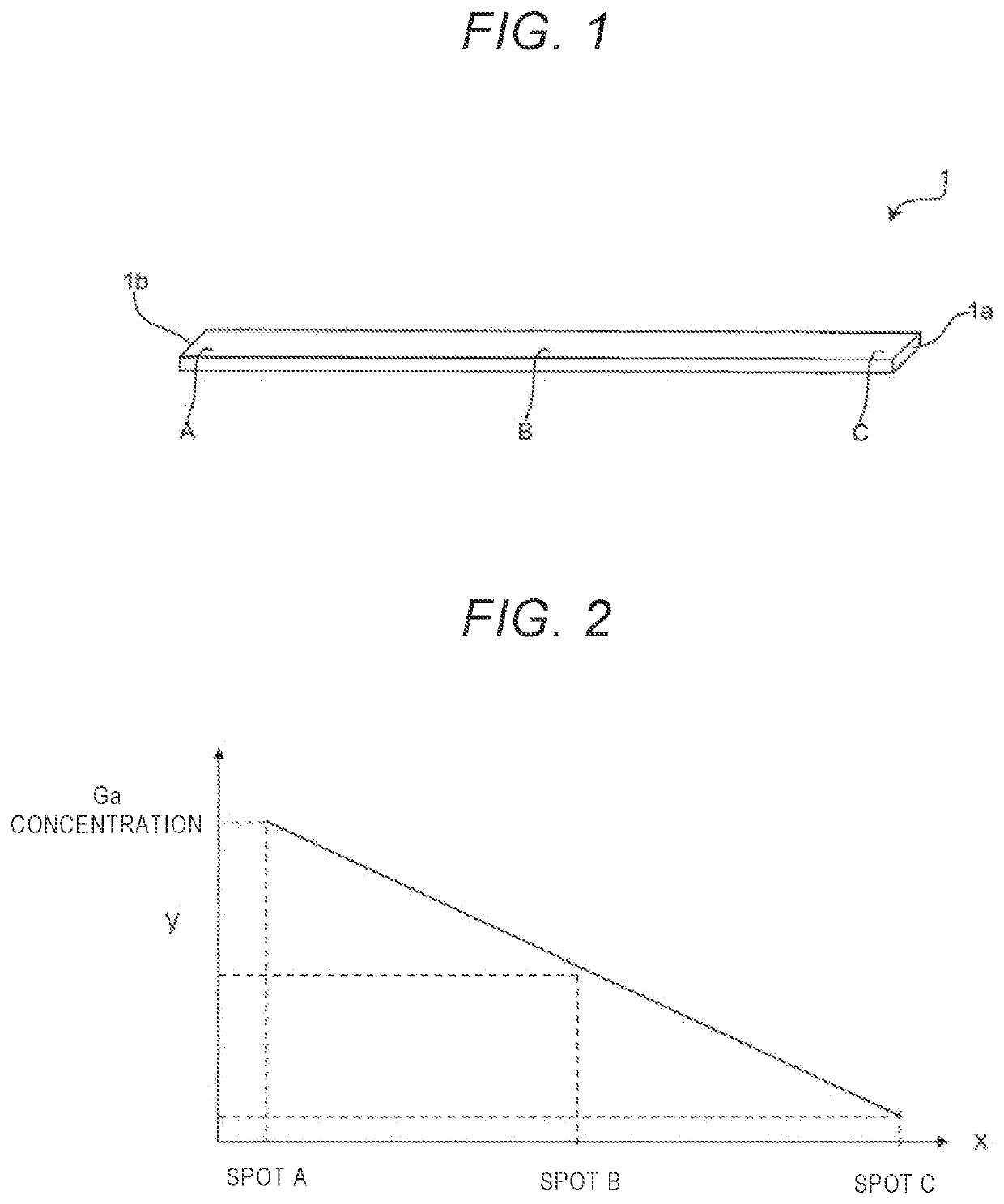

[0061]In Example 1, a plate-shaped FeGa-alloy magnetostriction element was produced that had varying Ga concentrations along its longitudinal direction. The magnetostriction element was then measured for magnetic flux density under no applied stress and under applied compressional stress, and changes occurring in magnetic flux density were confirmed.

Production of Magnetostriction Element

[0062]In order to produce an FeGa-alloy magnetostriction element of

[0063]Example 1-1, iron (purity 99.999%) and gallium (purity 99.999%) were weighed with an electronic balance. The content of each element in alloy specimens was measured and adjusted by EPMA analysis.

[0064]Specimens were grown using a high-frequency dielectric heating CZ furnace. A dense alumina crucible measuring 45 mm in outer diameter (ϕ) was disposed inside a graphite crucible having an inner diameter ϕ of 50 mm, and weighed 400 g of Fe and Ga was supplied as raw materials of each alloy specimen. The crucibles charged with the ra...

example 2

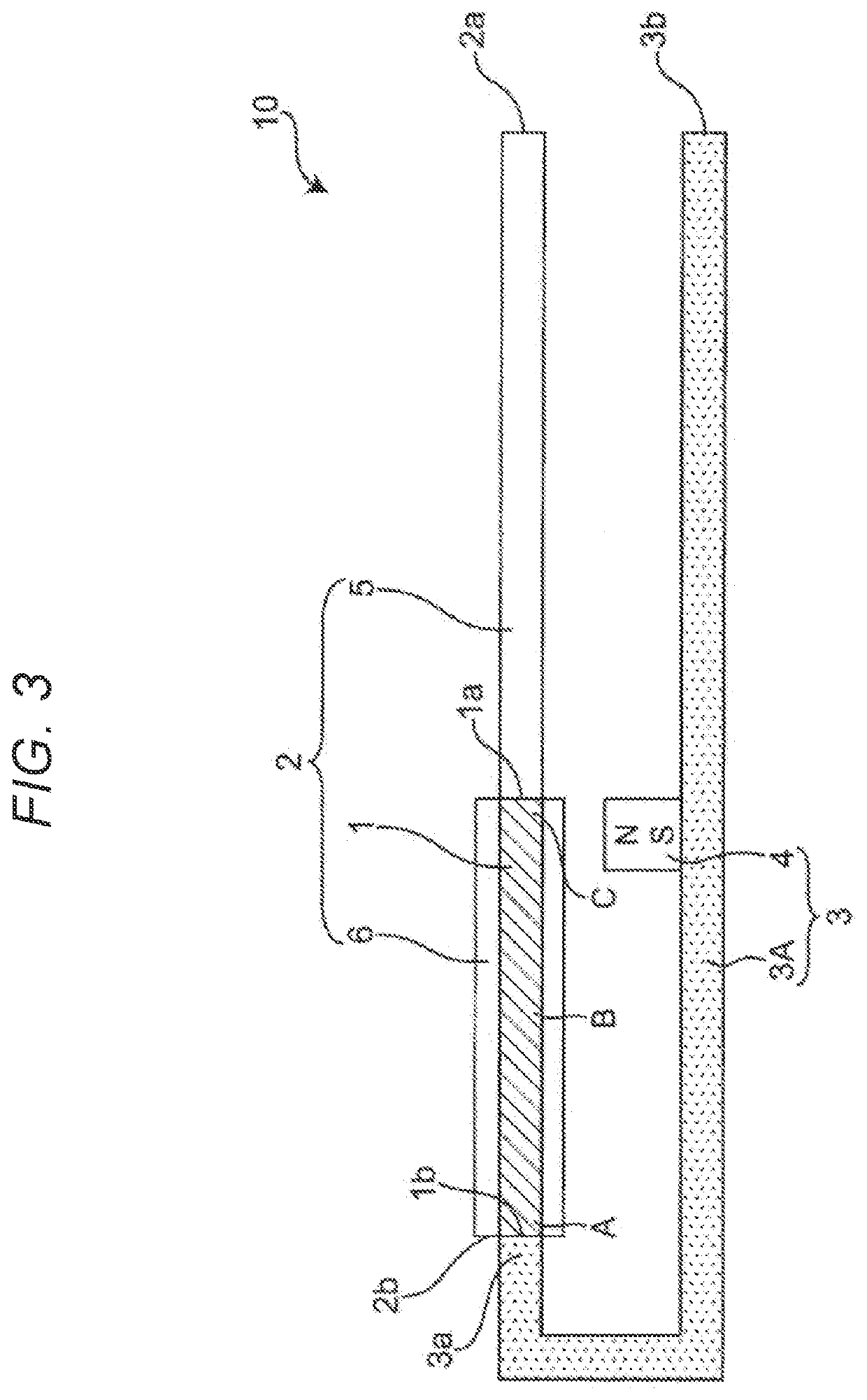

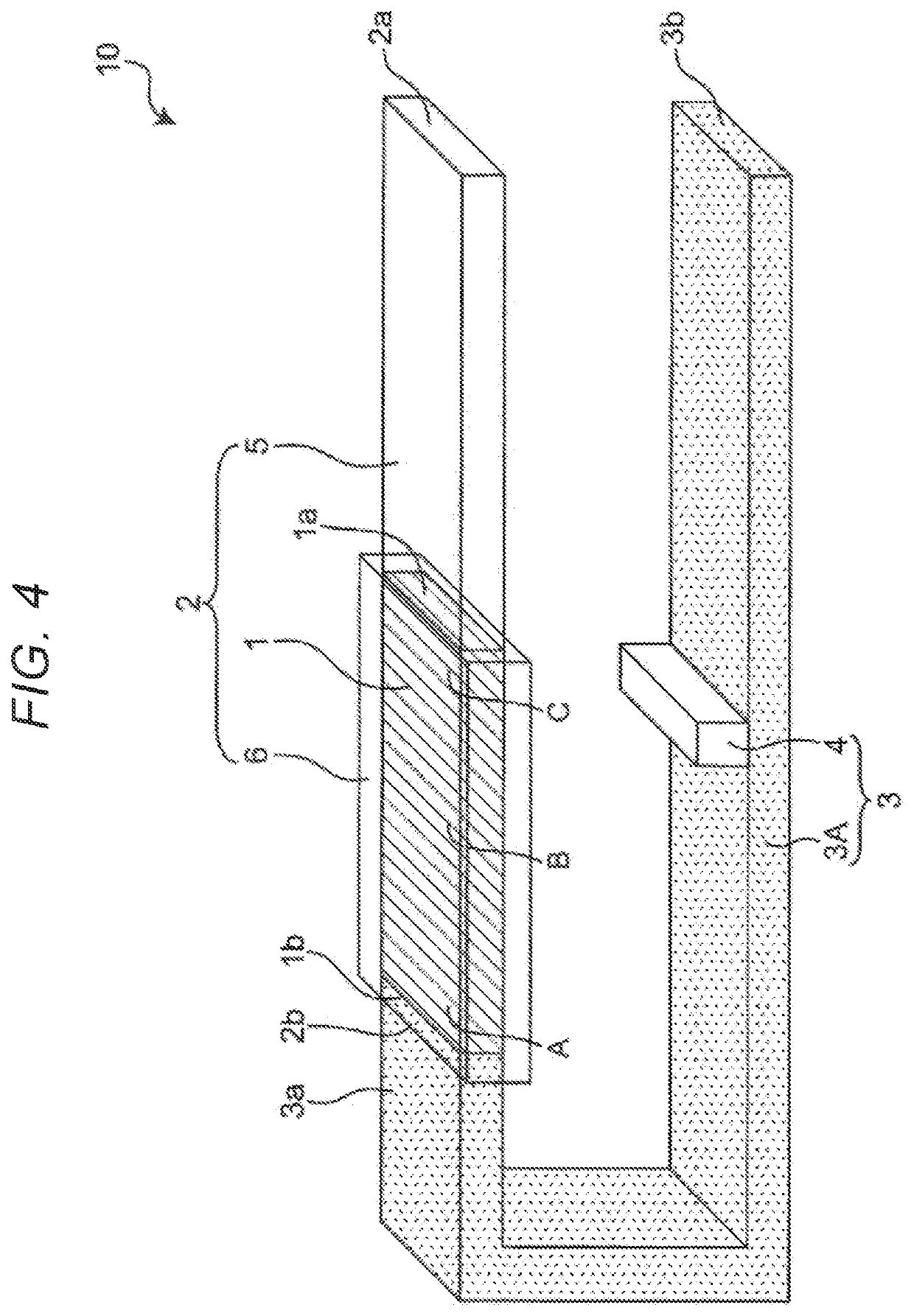

[0074]In Example 2, magnetostriction elements of various Ga concentrations were produced in the same manner as for the FeGa-alloy magnetostriction element of Example 1-1. These were then measured for magnetic flux density under no applied stress and under applied compressional stress, and changes occurring in magnetic flux density were confirmed. For the evaluation of the power density of each magnetostriction element, the magnetostriction element was installed in a magnetostriction-type vibration powered generator of the configuration shown in FIGS. 3 and 4, and measured for power density.

[0075]The magnetostriction elements used for measurement had a plate shape as in Example 1-1. The Ga concentrations in the magnetostriction elements had the values shown in Table 2 at spots A, B, and C as measured by EPMA analysis (the rest is the Fe concentration (at %)). In Examples 2-1 to 2-4, the magnetostriction elements had varying Ga concentrations at spots A, B, and C. The magnetostriction...

example 3

[0084]In Example 3, the Ga concentration of the FeGa alloy of Example 1-1 was varied, and a trace amount of Sm, Cu, or C was added to produce magnetostriction elements. For the evaluation of the power density of the magnetostriction element, the magnetostriction element was installed in the magnetostriction-type vibration powered generator in the same manner as in Example 2, and the power density was measured to confirm the effectiveness of adding these additional elements.

Evaluation of Power Density in Magnetostriction-Type Vibration Powered Generator Equipped with Magnetostriction Element

[0085]The magnetostriction elements used for measurement had a plate shape as in Example 1-1. The Ga concentrations (at %) at spots A, B, and C of the magnetostriction elements had the values shown in Tables 3-1 and 3-2 (spot A: 19; spot B: 17.5; spot C: 16) and in Tables 4-1 and 4-2 (spot A: 17; spot B: 15.5; spot C: 14) as measured by EPMA analysis. Tables 3-1 and 3-2 and Tables 4-1 and 4-2 also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com